Key Features and Benefits of Shanghe EPS Sandwich Panels

Our EPS sandwich panels are designed to meet global construction needs, offering superior performance in multiple aspects:

- Lightweight yet strong – Reduces structural load and simplifies handling.

- Excellent thermal insulation – Maintains stable indoor temperatures, lowering energy costs.

- Moisture and corrosion resistance – Outer steel skins with protective coatings ensure long service life.

- Quick and easy installation – Interlocking design shortens project timelines.

- Cost-effective solution – Ideal for large-scale projects and budget-conscious developments.

- Customizable – Available in various thicknesses, finishes, and colors.

- Eco-friendly – EPS core is recyclable and safe for the environment.

Application Areas and Industry Usage

Shanghe’s EPS core roof and wall panels are used in a wide range of industries and building types. Their versatility makes them suitable for both functional and aesthetic purposes:

- Cold storage and refrigeration facilities – Excellent thermal control maintains desired temperatures efficiently.

- Industrial warehouses – Lightweight construction allows fast installation and large-span solutions.

- Commercial buildings – Offices, shopping centers, and retail outlets benefit from energy savings and modern aesthetics.

- Prefabricated modular buildings – Quick setup for construction site offices, temporary housing, and event structures.

- Agricultural structures – Ideal for livestock shelters, greenhouses, and food processing units.

For specialized fire-resistant requirements, we also provide alternative solutions such as fireproof rock wool sandwich panels.

Quick Specifications Overview

| Property | Specification Range |

|---|

| Core Material | Expanded Polystyrene (EPS) |

| Outer Facing | Color-coated steel, galvanized steel, aluminum |

| Panel Thickness | 50mm – 200mm |

| Standard Width | 950mm / 1150mm |

| Length | Custom up to 12m |

| Thermal Conductivity | 0.035 – 0.041 W/m·K |

| Fire Rating | B1/B2 (custom B-s1-d0 available on request) |

| Density of EPS Core | 8 – 20 kg/m³ |

About Shanghe China EPS Sandwich Panel Manufacturer

Shanghe is a leading EPS sandwich panel manufacturer in China, supplying high-performance building panels to clients in the United States and worldwide. We focus on delivering durable, lightweight, and cost-effective EPS insulated sandwich panels for industrial, commercial, and residential projects. For over a decade, we’ve built our reputation on consistent quality, reliable delivery, and the ability to customize panels for U.S. building codes and application needs.

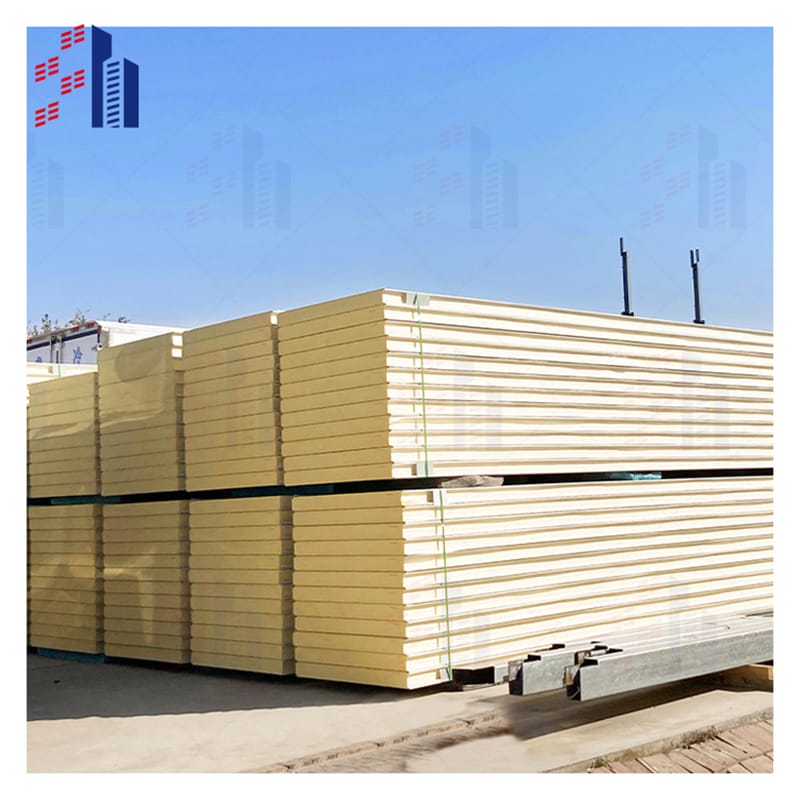

Production Facilities and Capacities

Our manufacturing base operates with modern, fully automated production lines designed for continuous panel production. This ensures better precision, higher efficiency, and uniform quality in every batch.

- Annual capacity: Over 3 million square meters of EPS core roof and wall panels

- Facilities: Multiple lines for galvanized steel, color-coated steel, and aluminum-faced panels

- Production speed: Capable of handling large-scale U.S. orders with fast turnaround

- Process control: Automated cutting, forming, EPS foaming, and lamination for consistent results

Quality Assurance and Certifications

We follow strict quality management systems to meet both international building standards and U.S. market requirements. Every batch undergoes numerous checks before shipment.

- Certifications: ISO 9001, CE, and SGS tested

- Standards compliance: Meets ASTM standards for insulation and safety where required

- Testing coverage: Thermal performance, structural strength, fire resistance, and surface coating durability

- Traceability: Each panel can be traced back to its raw material lot for quality tracking

EPS Sandwich Panel Specifications

Core Material Expanded Polystyrene EPS

Our EPS insulated sandwich panels use a rigid Expanded Polystyrene (EPS) core. EPS is lightweight, closed-cell foam that offers reliable thermal insulation, stable performance, and moisture resistance. It is ideal for both roof and wall panel systems in commercial, industrial, and cold storage applications.

Key EPS Core Benefits:

- Excellent thermal insulation (low thermal conductivity)

- Resistant to moisture and mold growth

- Lightweight for easier handling and installation

- Stable performance over time without sagging or settling

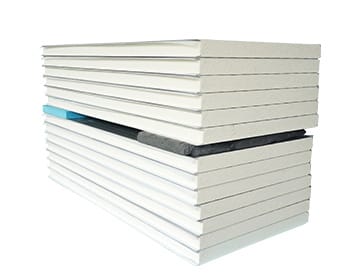

Cover Material Options

We offer multiple facing options to meet different environmental and strength needs:

- Galvanized steel sheets for corrosion resistance and durability

- Color-coated steel sheets for visual appeal and extra protection

- Aluminum sheets for lightweight applications and high corrosion environments

Sizes and Thickness Variants

Shanghe EPS panels come in standard sizes but can also be customized for project requirements.

| Specification | Range / Option |

|---|

| Panel Width | Standard 950 mm, 1150 mm |

| Panel Length | Up to 12 meters (custom available) |

| Panel Thickness | 50 mm, 75 mm, 100 mm, 150 mm, 200 mm |

| Steel Thickness | 0.3 mm – 0.8 mm |

Thermal Insulation Properties

- Thermal Conductivity (K-value): ≤ 0.038 W/m·K

- Estimated R-Value: R-2.6 to R-8 depending on thickness

- Keeps internal temperature stable, reducing HVAC load in U.S. warehouses, cold rooms, and prefab buildings

Fire Resistance and Safety Compliance

- EPS panels can be produced to meet local fire safety codes (options for flame-retardant EPS cores available)

- Meets ASTM and EN fire classifications for safe building use

- Optional fire-retardant additives improve resistance without compromising insulation

Customization and Solutions for EPS Sandwich Panels

As a China EPS sandwich panel manufacturer, Shanghe understands that every project in the U.S. market comes with its own requirements. That’s why we offer fully customizable options to make sure you get panels that match your building specs, climate needs, and design goals.

Custom Panel Thickness and Dimensions

We provide a wide range of thickness and size options to fit different applications — whether you need better insulation for cold storage or stronger load resistance for industrial walls.

| Specification | Options Available |

|---|

| Panel Thickness | 50mm, 75mm, 100mm, 125mm, 150mm, 200mm |

| Standard Width | 950mm, 1000mm, 1150mm |

| Length | Cut-to-size up to 12 meters |

| Core Density | 8–20 kg/m³ EPS |

Key Benefit: Thicker panels improve thermal insulation (higher R-values) and structural strength for heavy-duty use.

Color and Coating Options

Our cover sheets can be finished in galvanized steel, color-coated steel, or aluminum, with a wide selection of colors to match architectural styles used in the U.S.

- Standard RAL color range available

- Anti-corrosion coatings for harsh climates

- Smooth or embossed finishes

Tip: Darker colors work well for industrial buildings, while light tones help reflect heat in hot states like Texas, Arizona, and Florida.

Specialized EPS Panel Solutions

Shanghe develops project-specific EPS insulated sandwich panel solutions for different industries:

- Cold Storage Panels – High-density EPS cores, vapor-tight coatings, and precise joint sealing to maintain temperature control.

- Commercial Buildings – Attractive finishes, smooth facades, and optimal insulation for energy-efficient retail spaces, offices, or showrooms.

- Industrial Warehouses – Stronger skins, load-bearing capability, and impact resistance for heavy-duty environments.

- Prefabricated Structures – Lightweight panels for quick assembly and easy transportation, ideal for temporary or modular buildings.

Why Customization Matters

Customizing EPS sandwich panels ensures you pay only for the performance you need — whether it’s maximum insulation, structural strength, or specific design aesthetics. U.S. customers benefit from lightweight construction, reduced energy costs, and compliance with local building codes.

Manufacturing and Quality Control Process for EPS Sandwich Panels

Raw Material Sourcing

As a leading China EPS sandwich panel manufacturer, Shanghe sources only premium-grade expanded polystyrene (EPS) from trusted suppliers. The steel skins—whether galvanized, pre-painted color-coated, or aluminum—are procured from mills that meet ISO and CE standards. This ensures each panel has a consistent EPS core density and durable metal exterior for long-term performance.

Production Line Technology

We operate fully automated continuous production lines in our modern EPS sandwich panel factory. The process ensures:

- Consistent EPS core bonding with metal sheets

- High-speed precision cutting for custom sizes without edge defects

- Uniform thickness with tight tolerances

- Smooth, even coating finishes on all panels

Our technology covers both roofing and wall-type EPS insulated sandwich panels for commercial, industrial, and cold storage usage.

Quality Testing Procedures

Every EPS panel batch undergoes strict in-house testing to meet U.S. and international standards:

- Mechanical Strength Test – Checks load-bearing capacity for structural use

- Thermal Performance Test – Measures insulation efficiency (R-value, thermal conductivity)

- Fire Resistance Test – Ensures compliance with safety codes for building applications

- Surface Adhesion & Finish Inspection – Guarantees paint quality and lamination durability

Our QC team uses SGS-certified measuring equipment to verify all parameters before shipment.

Packaging Handling and Logistics

To protect panels during transport, we use:

- PE film wrapping for moisture protection

- Foam corner guards to prevent dents or edge damage

- Palletized bundling for easy forklift handling

For U.S. buyers, we offer export-ready packaging with fumigation-compliant wooden pallets. Panels are shipped via sea freight or intermodal transport, ensuring safe delivery to your project site, whether it’s a prefabricated building, cold storage facility, or warehouse expansion.

Pricing and Ordering Information for China EPS Sandwich Panel Manufacturer

Price Ranges Based on Specification

As a leading EPS sandwich panel manufacturer in China, Shanghe offers competitive pricing tailored to your project needs. Prices depend on factors like core thickness, facing material, coating type, and order volume.

Typical price considerations:

- Core thickness: Thicker EPS cores cost more but offer higher insulation.

- Facing material: Color-coated steel is typically more affordable than aluminum.

- Custom finishes: Non-standard colors or special coatings may raise unit costs.

| Specification | Price Influence | Notes |

|---|

| EPS Core Thickness (50mm – 200mm) | Higher thickness → higher cost | Improves insulation performance |

| Facing Material (PPGI, Galvanized Steel, Aluminum) | Aluminum is premium option | Choice impacts durability and aesthetics |

| Coating Type | Polyester, PVDF | PVDF offers better weather resistance |

| Order Quantity | Larger volumes lower unit price | Advisable for big projects |

Minimum Order Quantity

Our MOQ starts at 500㎡ for standard EPS insulated sandwich panels. Custom sizes, non-standard colors, or special applications (such as cold storage sandwich panels) may require different MOQs.

Delivery Options Domestic and Export

We ship domestically within China and export worldwide, including to the United States market.

- Lead time: Typically 7–15 days for standard production orders. Large or custom orders may take longer.

- Shipping methods: Sea freight, rail, and containerized truck delivery.

- Packaging: Panels are packed with protective films and bundled for safe transit.

Samples and Technical Support

- Samples: Available upon request to verify core density, facing finish, and overall quality before placing bulk orders.

- Technical Assistance: Our team provides installation guidance, load calculations, and thermal performance advice tailored to U.S. building codes.

- Custom Orders: Full design and production support for special panel applications, including steel foam sandwich panel solutions and other advanced insulated panel options.

After Sales Service for Shanghe EPS Sandwich Panels

Warranty Terms

We stand behind every EPS insulated sandwich panel we produce. All Shanghe panels come with a standard 10-year warranty covering:

- Structural integrity against warping or delamination

- Thermal insulation performance within rated R-value range

- Coating adhesion for galvanized and color-coated steel option panels

Extended warranties are available for large-scale U.S. projects or custom orders.

Technical Support

Our technical team works with U.S. customers directly to ensure smooth installation and performance. We provide:

- Pre-installation consultations for design and load calculations

- Material compatibility advice for roofing, wall, and cold storage systems

- Troubleshooting assistance during or after project completion

Support is available via email, phone, or live video call during U.S. business hours.

Installation Guidance and Resources

Even though our lightweight EPS panels are straightforward to install, we make sure you get it right the first time. We offer:

- Step-by-step installation manuals for roof and wall applications

- Video tutorials with practical tips for cutting, sealing, and fastening

- On-site supervision for large-scale commercial or industrial builds (by request)

- Best practices for fire safety compliance and long-term durability

Customer Testimonials and Case Studies

Our EPS sandwich panels are already serving various industries across the United States:

- Cold storage warehouses in Texas maintained stable temperature even in peak summer

- Prefabricated housing projects in Florida withstood hurricane season without damage

- Industrial workshop builds in California improved energy efficiency by over 30%

Example: A national food distributor in Ohio replaced older insulated panels with Shanghe’s fire-resistant EPS wall panels and cut cooling costs by $15,000 annually.

FAQs about Shanghe EPS Sandwich Panels

What is an EPS Sandwich Panel

An EPS sandwich panel is a lightweight, insulated building panel made with an expanded polystyrene (EPS) foam core between two layers of metal, usually color-coated steel, galvanized steel, or aluminum. It’s designed to provide thermal insulation, structural strength, and a finished surface in one product.

Common uses include cold storage facilities, warehouses, prefab buildings, roofing, and wall cladding.

How Shanghe EPS Panels Compare with Other Core Materials

Shanghe’s EPS panels deliver a cost-effective, highly lightweight, and easy-to-install option compared to other cores like polyurethane (PU) or rock wool.

- Better value for general insulation where extreme fire resistance is not the main requirement

- Lower weight for easier transport and installation

- Good thermal performance for moderate to cold climates

- Faster production & delivery due to simpler processing compared to PU or PIR panels

For projects needing ultra-high fire resistance, mineral wool cores may be considered. But for most commercial, industrial, and agricultural buildings in the U.S., EPS cores meet performance and budget needs effectively.

Are Customized Panels Available

Yes. Shanghe provides custom EPS sandwich panel manufacturing with options for:

- Length, width, and thickness according to building design

- Panel colors matched to project branding or aesthetic needs

- Surface coatings for corrosion resistance, UV stability, or enhanced hygiene

- Special panel types for cold rooms, roofing systems, or soundproofing applications

Typical Lead Time for Orders

Lead times depend on panel size, quantity, and customization level:

- Standard sizes & colors: usually 7–10 days after order confirmation

- Custom sizes/colors: typically 10–15 days

- Large export projects: may require additional production and shipping time

Shanghe’s high-capacity production lines help ensure a consistent and reliable supply, even for bulk orders.

How to Maintain EPS Sandwich Panels

EPS panels require minimal upkeep, but following basic care helps extend lifespan:

- Clean periodically with mild soap and water to remove dirt and debris

- Inspect joints and fasteners for any damage or loosening

- Avoid high-pressure washing directly at seams to prevent water infiltration

- Touch up scratches on coated steel surfaces to avoid corrosion

- Keep panels free from prolonged contact with strong solvents or chemicals that can damage the EPS core

Contact and Inquiry for China EPS Sandwich Panel Manufacturer

If you’re looking for a reliable China EPS sandwich panel manufacturer for your building or insulation projects, we’ve made it easy to get in touch. Whether you need quick pricing, technical details, or want to arrange a factory visit, we respond quickly and provide accurate information.

Direct Contact Information

You can reach our sales and technical support team directly for all inquiries on EPS insulated sandwich panels:

- Phone (International): +86-XXX-XXXX-XXXX

- Email: sales@shanghepanel.com

- WeChat/WhatsApp: +86-XXX-XXXX-XXXX

- Address: Shanghe Industrial Zone, [City], China

Business Hours: Monday–Saturday, 8:00 AM–6:00 PM (China Standard Time)

U.S. Customers: We adapt to time zones and can schedule late-evening or early-morning calls for your convenience.

Online Inquiry Form

For fast quotes or technical documentation, use our online inquiry form on our official website.

- Fill in panel type, thickness, color, length, and quantity

- Add delivery location (U.S. port or warehouse)

- We reply within 24 hours with prices, lead times, and shipping options

Factory Visits and Consultation

Visiting our EPS sandwich panel manufacturing plant in China allows you to:

- Inspect production lines for EPS core roof and wall panels

- Review quality control procedures and certifications (ISO, CE, SGS)

- Discuss customization options for specific U.S. climate conditions (cold storage, industrial, commercial use)

- See ready-made cold storage sandwich panels and prefabricated building solutions in stock

Note: International clients can request virtual factory tours if traveling to China isn’t possible.