Foam Sandwich Panels Composition and Structure

Foam sandwich panels are engineered building materials designed to offer exceptional insulation, strength, and lightweight properties. These panels consist of two main components: the face sheets and the core material. Understanding their composition is essential to selecting the right panel for your project.

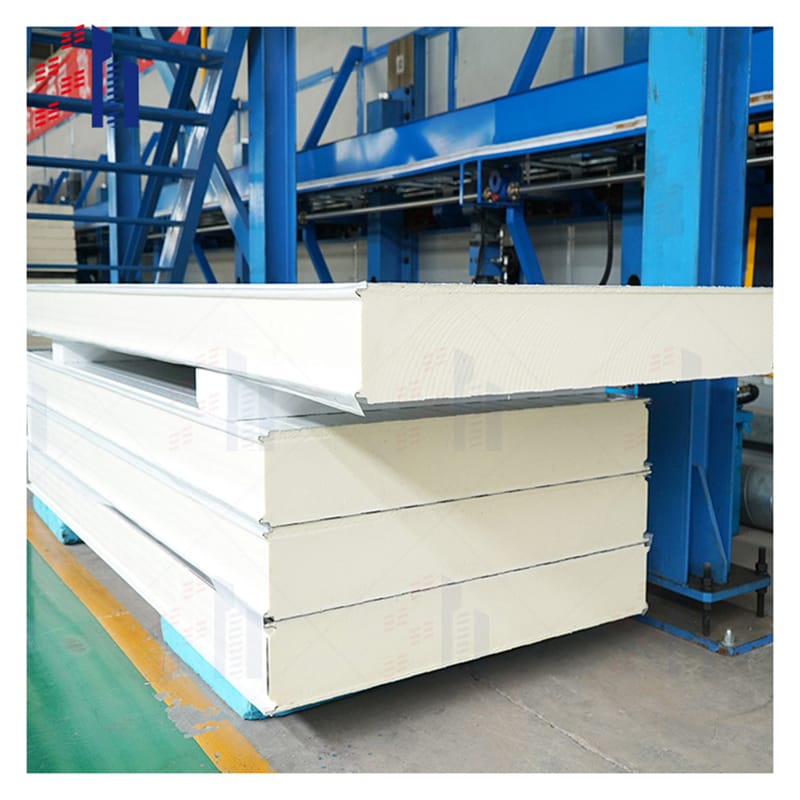

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Face Sheets

The face sheets are the outer layers of foam sandwich panels, providing structural support, durability, and protection. Typically made from steel, aluminum, or fiber-reinforced plastic (FRP), these sheets carry the load and resist external forces, including weather, impact, and wear. The choice of face sheet depends on the application and desired performance:

- Steel face sheets offer high strength, excellent fire resistance, and durability, ideal for commercial construction and industrial buildings.

- Aluminum face sheets are lightweight and corrosion-resistant, perfect for specific transport and marine uses.

- FRP face sheets provide superb chemical resistance and lighter weight, commonly used in specialty applications like cleanrooms.

Core Materials

At the heart of foam sandwich panels is the core material, which defines much of the panel’s performance, especially its thermal insulation, weight reduction, and rigidity. The core is typically made from various foam types, each with unique properties:

- Polyurethane (PUR) foam delivers excellent thermal insulation with a high R-value and good mechanical strength.

- Polyisocyanurate (PIR) foam offers superior fire resistance alongside high insulation performance.

- Expanded Polystyrene (EPS) foam provides cost-effective insulation, lightweight structure, and versatility.

- Extruded Polystyrene (XPS) foam features enhanced moisture resistance and compressive strength, making it suitable for demanding environments.

Each core material is sandwiched between the face sheets and securely bonded during manufacturing for maximum structural integrity. The combination of durable face sheets and high-performance foam cores creates panels that are strong, lightweight, and thermally efficient — ideal for modern construction and industrial use.

Key points to remember about foam sandwich panel composition:

- Face sheets bear structural loads and protect the core.

- Core materials determine insulation efficiency and weight.

- The bonding process ensures durability and stability.

- Material choices depend on application-specific needs such as fire resistance, moisture resistance, or cost.

Selecting the proper face sheet and core type is critical for maximizing the benefits of foam sandwich panels, delivering reliable, energy-efficient building solutions.

Types of Foam Sandwich Panels

Foam sandwich panels come in several types, each offering unique benefits depending on your project needs. Here’s a quick breakdown of the most common foam core options used in insulated sandwich panels:

Polyurethane PUR Panels

Polyurethane (PUR) foam panels are widely used for their excellent thermal insulation and lightweight nature. These panels provide a high R-value, making them ideal for construction foam panels in walls, roofs, and facades where energy efficiency is a priority. PUR panels also offer good fire resistance and a strong bond between the foam core and the metal or composite face sheets.

Polyisocyanurate PIR Panels

Polyisocyanurate (PIR) sandwich panels offer superior thermal insulation compared to standard PUR panels, thanks to a higher R-value. PIR foam panels are also more fire-resistant, making them a great choice for fire-resistant sandwich panels in commercial buildings, warehouses, and cold storage facilities. These panels provide a balance of durability and strength with lightweight building materials applications.

Expanded Polystyrene EPS Panels

Expanded Polystyrene (EPS) foam panels are a cost-effective option in the foam sandwich panels market. EPS foam offers decent thermal insulation but generally has a lower fire resistance rating compared to PIR and PUR panels. EPS panels are commonly used in construction foam panels for residential buildings and interior partitions where budget and thermal performance need to align.

Extruded Polystyrene XPS Panels

Extruded Polystyrene (XPS) sandwich panels provide superior moisture resistance and compressive strength compared to EPS panels. This makes XPS foam panels suitable for cold storage panels and areas prone to humidity. They also boast moderate thermal insulation and are excellent for use in industrial buildings and refrigerated transportation containers.

Choosing the right foam core depends on your project’s thermal insulation needs, fire safety requirements, budget, and environmental conditions. Each type has its place in the U.S. construction and industrial market, ensuring foam sandwich panels deliver performance where it counts.

Foam Sandwich Panels Key Properties

Foam sandwich panels are known for their excellent combination of thermal insulation, fire resistance, strength, and sound insulation. Here’s a closer look at these key properties that make them a go-to choice for many construction and industrial projects in the U.S.

Thermal Insulation and R-value

One of the biggest selling points of foam sandwich panels is their superior thermal insulation performance. The foam core—often polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), or extruded polystyrene (XPS)—provides high R-values, meaning better resistance to heat flow. This translates to:

- Lower energy costs for heating and cooling

- Improved indoor comfort

- Reduced carbon footprint

In fact, panels with PUR or PIR foam cores typically offer R-values of 6 to 7 per inch of thickness, making them highly effective for insulation in walls, roofs, and cold storage facilities.

Fire Resistance

Fire safety is critical in construction, especially in commercial and industrial settings. Foam sandwich panels can meet stringent fire resistance standards thanks to:

- Fire-retardant additives in PIR and specific PUR foams

- Ratings that comply with ASTM E84 and UL 94

- Ability to resist flame spread and reduce smoke production

Panels like PIR sandwich panels are notably fire-resistant, making them ideal for applications where fire safety can’t be compromised. For projects demanding extra protection, fireproof options such as rock wool sandwich panels could also be considered. Explore our fireproof sandwich panels.

Lightweight and High Strength-to-Weight Ratio

Foam sandwich panels offer an excellent strength-to-weight ratio. This means they are:

- Lightweight, reducing load on building structures

- Easy to handle and install, speeding up construction time

- Strong enough to withstand wind, impact, and structural loads

This makes them highly desirable for both large-scale buildings and mobile applications like RVs and shipping containers.

Sound Insulation

Besides thermal benefits, these panels help reduce noise transmission, creating quieter, more comfortable interiors. The foam core acts as a sound barrier by:

- Absorbing and dampening noise vibrations

- Reducing echoes in industrial or commercial spaces

This is particularly useful in settings like modular homes, cleanrooms, and warehouses where noise control matters.

When you choose foam sandwich panels, you invest in a versatile material that offers energy efficiency, safety, durability, and comfort. To find panels perfectly suited to your project’s insulation and fire-resistance needs, check out our full range, including premium polyurethane sandwich wall panels and PIR panels.

Benefits of Foam Sandwich Panels Energy Efficiency and Cost Savings

Foam sandwich panels are a smart choice when it comes to energy efficiency in building projects. Thanks to their high-performance thermal insulation, these panels help maintain consistent indoor temperatures by reducing heat transfer. This means less reliance on heating or cooling systems, which directly lowers your utility bills. The R-value of the foam core—whether it’s polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), or extruded polystyrene (XPS)—is key to how well the panel insulates. Panels with higher R-values deliver better energy savings.

How Foam Sandwich Panels Save You Money

- Reduced energy consumption leads to lower monthly heating and cooling costs.

- Their lightweight nature makes installation faster and less labor-intensive, cutting construction costs.

- Excellent air sealing properties minimize drafts and heat loss, which adds to energy savings.

- Long-lasting insulation means fewer replacements or upgrades, reducing maintenance expenses over time.

Using foam sandwich panels can significantly improve the energy performance of walls, roofs, and facades, especially in residential and commercial construction across the U.S. market where energy codes are becoming stricter.

By choosing foam sandwich panels, you invest in a product that not only delivers superior thermal insulation but also helps you cut operational costs and boosts the overall energy efficiency of your building. This makes them an ideal option for projects focused on sustainability and long-term savings.

Benefits of Foam Sandwich Panels Durability and Low Maintenance

One of the biggest advantages of foam sandwich panels is their durability and minimal upkeep needs. These panels are built to last, combining tough outer face sheets with a resilient foam core that resists wear and damage over time.

Long-Lasting Performance

The face sheets—usually made from steel, aluminum, or fiberglass—are designed to withstand harsh weather, UV exposure, and mechanical impacts without corroding or degrading. This protective layer keeps the foam core safe, preserving its insulating properties and structural integrity for years.

Resistant to Moisture and Chemicals

Unlike traditional building materials, these insulated sandwich panels resist moisture absorption. This lowers the risk of mold, mildew, or core damage. Many options, like polyurethane foam panels and PIR sandwich panels, also offer excellent chemical resistance, making them ideal for industrial and refrigerated environments where exposure to chemicals is common.

Low Maintenance Requirements

Because of their durability, foam sandwich panels need little maintenance. Simple cleaning with mild detergent and water is usually enough to keep them looking good and functioning well. No need for frequent repainting, sealing, or repairs, which saves time and reduces ongoing costs.

Impact on Project Longevity and Costs

Using high-quality foam sandwich panels for construction not only improves the lifespan of your building envelope but also lowers long-term maintenance expenses. This makes them a smart investment, especially in U.S. climates where weather conditions can vary widely.

Key points to remember:

- Tough outer skins protect against weather, UV, and physical damage

- Foam cores resist moisture, mold, and chemical impacts

- Minimal cleaning and no frequent repairs needed

- Longer lifespan means cost savings over time

Durability and low maintenance are essential reasons why foam sandwich panels are trusted across commercial, industrial, and residential projects in the United States.

Benefits of Foam Sandwich Panels Versatility Across Applications

Foam sandwich panels offer exceptional versatility, making them a top choice for a wide range of projects throughout the United States. Their unique structure — combining sturdy face sheets with a lightweight foam core — allows these panels to adapt to different requirements across industries.

Multi-Industry Use

- Construction: They’re a favorite for walls, roofs, and facades due to their excellent insulation and structural strength. This versatility helps builders meet energy codes while speeding up installation.

- Cold Storage and Refrigeration: Foam sandwich panels provide superior thermal insulation, keeping storage at consistent low temperatures, essential for perishable goods.

- Industrial Facilities and Warehouses: Their durability and lightweight build make them ideal for large-scale industrial applications where efficiency and strength are key.

- Transportation: From RVs to shipping containers, these panels reduce weight without compromising strength, improving fuel efficiency and ease of handling.

- Specialty Applications: Cleanrooms, modular homes, and other specialized projects benefit from the panels’ customizable size and material options.

Adaptable to Project Needs

- Foam core options like Polyurethane (PUR), Polyisocyanurate (PIR), Expanded Polystyrene (EPS), and Extruded Polystyrene (XPS) allow you to tailor thermal performance and fire resistance.

- Panel thickness and face material choices ensure the right balance of strength, insulation, and aesthetics depending on your unique project needs.

- Custom fabrication means panels can fit precise dimensions, shapes, and even design features, making them practical for both new builds and retrofit work.

Why Versatility Matters for US Buyers

In a market where construction and energy efficiency standards vary by state, having a single product that adapts well to multiple use cases means fewer supply chain headaches and lower overall costs. Plus, foam sandwich panels help streamline projects, reducing labor and materials waste.

In short: Foam sandwich panels combine lightweight strength, high insulation values, and adaptability, making them an all-around solution for diverse building and industrial applications across the US market.

Benefits of Foam Sandwich Panels Eco-Friendly and Sustainable Options

When choosing construction materials today, eco-friendliness and sustainability are crucial factors. Foam sandwich panels offer several key advantages that make them a responsible choice for green building projects and energy-conscious customers in the U.S. market.

Reduced Environmental Impact

Foam sandwich panels, such as polyurethane (PUR) foam panels and expanded polystyrene (EPS) foam panels, are designed to minimize environmental harm by improving energy efficiency in buildings. Their excellent thermal insulation properties help reduce heating and cooling demands, lowering overall energy consumption and carbon emissions.

Use of Recyclable Materials

Many foam sandwich panels are manufactured using materials that can be recycled or reused, reducing landfill waste. For example, EPS core materials can be recycled back into new foam products. Some suppliers, including leading manufacturers like Shanghe, focus on sourcing foam sandwich panel components that comply with environmental protection standards, supporting circular economy goals.

Lightweight Construction Means Less Resource Use

Because foam sandwich panels are lightweight yet strong, they require less structural support compared to traditional heavy materials. This means:

- Reduced use of steel or concrete frameworks

- Lower transportation emissions due to lighter loads

- Easier, faster installation minimizing waste on-site

Low VOC Emissions and Safe Indoor Air Quality

High-quality foam sandwich panels are produced with low or zero volatile organic compounds (VOCs), which improves indoor air quality. Choosing panels certified for low VOC emissions enhances occupant health and meets U.S. green building standards like LEED.

Foam sandwich panels offer a sustainable building solution by combining recycled content, energy efficiency, reduced structural demands, and healthier indoor environments. For eco-conscious builders and developers, these panels contribute not just to project success but to a greener future.

Explore more about Shanghe’s eco-friendly foam sandwich panels and their certifications to make your next project both high-performing and sustainable.

For details on EPS sandwich panels and other options, check out Shanghe’s product lines tailored for energy efficiency and environmental care.

Benefits of Foam Sandwich Panels Why Choose Shanghe’s Foam Sandwich Panels

When it comes to foam sandwich panels, Shanghe stands out by combining innovative manufacturing, tailored solutions, and trusted certifications. Here’s why our panels are a preferred choice for U.S. customers looking for reliable, high-performance insulated sandwich panels.

Advanced Manufacturing Processes

At Shanghe, we use state-of-the-art production techniques to ensure every foam sandwich panel meets strict quality and durability standards. Our process integrates:

- Precision lamination of face sheets and cores, guaranteeing strong bonding and consistent thickness

- Automated cutting and shaping for exact dimensions, reducing waste and speeding up installation

- Rigorous quality control at every stage to avoid defects and improve long-term performance

This superior manufacturing results in panels with excellent thermal insulation, fire resistance, and structural integrity that stand up well under U.S. climate conditions.

Customizable Solutions

We know projects vary — that’s why Shanghe offers custom foam sandwich panels tailored to your needs. Choose from different core materials like PUR, PIR, EPS, or XPS based on your thermal and fire safety requirements. You can also customize:

- Panel thickness and size options to fit specific construction plans or retrofit needs

- Face materials including steel, aluminum, plywood, or fiberglass for varied aesthetics and functionality

- Surface finishes for additional weather protection or sound insulation

Our flexible approach ensures you get the best foam sandwich panel solution that balances performance and budget.

Industry Certifications

Shanghe foam sandwich panels meet key U.S. and international certifications, giving you confidence in product safety and reliability. Our panels are:

- Tested and certified for fire performance, meeting standards for fire-resistant sandwich panels suitable for commercial and residential buildings

- Compliant with insulation requirements to support energy-efficient and sustainable building goals

- Recognized in quality management systems ensuring consistent product excellence and traceability

These certifications assure you of long-lasting, code-compliant foam sandwich panels ideal for walls, roofs, cold storage, and more.

Choosing Shanghe brings together advanced manufacturing, customization, and certified quality — making our foam sandwich panels the smart choice for projects that demand energy efficiency, durability, and peace of mind.

For specific panel options, check out our EPS foam panels and fire protection sandwich panels.

Applications of Foam Sandwich Panels in Construction Walls Roofs Facades

Foam sandwich panels are widely used in construction, offering lightweight building materials that deliver excellent performance for walls, roofs, and facades. Their unique structure—consisting of rigid foam cores bonded between durable face sheets—makes them ideal for a variety of building needs in the United States.

Walls

Foam sandwich panels provide superior thermal insulation with high R-values, helping walls maintain energy efficiency and reduce heating and cooling costs. They are excellent for both commercial and residential buildings, ensuring strong structural integrity while keeping buildings comfortable year-round. Their fire-resistant sandwich panel variants add an essential layer of safety, meeting local building codes and regulations.

Roofs

Using foam sandwich panels for roofs offers benefits like lightweight installation and excellent weather resistance. The panels reduce dead loads on structures, allowing for lighter roof framing and simpler installation. Their thermal insulation panels properties help prevent heat loss or gain, which is critical in maintaining energy savings across climates typical in the US. Moreover, these panels provide strong resistance against moisture, reducing risks of mold and mildew.

Facades

For building facades, foam sandwich panels combine aesthetics with performance. The construction foam panels can be customized with various finishes and textures, enhancing curb appeal while delivering high durability and impact resistance. Additionally, the panels’ insulating core improves overall building comfort and energy use, contributing to sustainability efforts in modern architecture.

foam sandwich panels in walls, roofs, and facades bring:

- Energy efficiency through excellent insulation

- Structural strength with lightweight properties

- Fire resistance compliance with safety standards

- Moisture and weather protection for long-term durability

- Customizable options fitting design needs

For US customers seeking reliable, efficient, and versatile foam sandwich panels for construction, these panels are a top choice for enhancing building performance and reducing operational costs.

Applications of Foam Sandwich Panels Cold Storage and Refrigeration

Foam sandwich panels are a top choice for cold storage and refrigeration facilities in the U.S. market because of their excellent thermal insulation, durability, and ease of installation. These panels help maintain precise temperature control, which is critical for storing perishable goods like food, pharmaceuticals, and other temperature-sensitive products.

Why Foam Sandwich Panels Work for Cold Storage

- Superior Thermal Insulation: The foam core, often made from polyurethane (PUR) or polyisocyanurate (PIR), provides a high R-value that effectively minimizes heat transfer. This means your cold room stays colder longer, reducing energy costs.

- Tight Sealing and Moisture Resistance: Cold storage demands panels that resist moisture infiltration to prevent condensation. Foam sandwich panels offer airtight seals between joints, helping maintain consistent humidity levels.

- Fire-Resistant Options: Certain foam sandwich panels, like PIR panels, come with enhanced fire resistance, meeting strict fire codes often required in commercial refrigeration.

- Lightweight but Sturdy: The combination of lightweight foam cores with durable metal or composite face sheets allows easier handling and quicker installation without sacrificing strength.

- Longevity in Harsh Conditions: These panels withstand harsh environments with minimal wear, which is essential for refrigerated warehouses and processing plants.

Typical Use Cases in Cold Storage

- Exterior and interior walls of walk-in freezers and refrigerated warehouses.

- Insulated ceilings and cold room partitions.

- Prefabricated cold storage units for rapid deployment.

- Refrigerated shipping container walls and doors.

For detailed product specs that fit cold storage needs, check out our PU Foam Sandwich Panels tailored for thermal insulation and durability.

Key Benefits for Refrigeration

- Energy Savings through high-performance insulation reduce operational costs.

- Maintained Product Quality by ensuring stable temperature and humidity.

- Quick Installation minimizes downtime during facility upgrades or new construction.

- Compliance with U.S. building codes for fire safety and insulation standards.

foam sandwich panels are a reliable, efficient solution for all your cold storage and refrigeration insulation needs, combining thermal performance with durability to keep your operation running smoothly.

Applications of Foam Sandwich Panels in Industrial Buildings and Warehouses

Foam sandwich panels are widely used in industrial buildings and warehouses due to their excellent combination of strength, insulation, and ease of installation. These construction foam panels provide a versatile solution that meets the demanding needs of large-scale industrial spaces.

Thermal Insulation and Energy Efficiency

Industrial facilities often require temperature control to protect equipment, goods, and processes. Foam sandwich panels, especially those with polyurethane foam cores (PUR panels) or polyisocyanurate cores (PIR panels), offer a high R-value for superior thermal insulation. This helps reduce heating and cooling costs, making warehouses and factories more energy-efficient.

Structural Strength and Durability

One of the challenges in industrial construction is ensuring panels can withstand heavy use and harsh environments. Foam sandwich panels have a high strength-to-weight ratio, meaning they are strong yet lightweight. The rigid core combined with durable face sheets (typically steel or aluminum) provides excellent impact resistance, structural integrity, and longevity – crucial for warehouse walls, roofing, and partitioning.

Fire Resistance and Safety

In industrial settings, fire safety is critical. PIR sandwich panels, known for their fire-resistant properties, meet strict safety standards. Using these panels helps protect buildings, lowers the risk of fire spreading, and can be a key factor in insurance and compliance.

Noise Reduction and Comfort

Noise from machinery and operations can affect worker comfort. Foam sandwich panels provide effective sound insulation, reducing noise levels inside industrial spaces and creating a more comfortable working environment.

Ease of Installation and Customization

Speed and flexibility are vital on the job site. Foam sandwich panels are designed for quick installation, with interlocking joints and pre-finished surfaces that save time and labor costs. They can be custom-sized and tailored to specific industrial project needs, whether it’s for new builds, expansions, or retrofits.

of Benefits for Industrial Use

- High thermal insulation reduces energy costs

- Lightweight but strong for easier handling and durability

- Fire-resistant options improve safety

- Sound dampening enhances workplace comfort

- Quick installation saves time and money

- Customizable sizes and finishes fit unique industrial requirements

Using foam sandwich panels in warehouses and industrial buildings ensures a balance of performance, safety, and cost-effectiveness—making them a top choice for modern industrial construction projects.

Applications of Foam Sandwich Panels in Transportation

Foam sandwich panels play a crucial role in transportation, especially for applications like RVs, shipping containers, and specialized transport units. Their combination of lightweight structure, thermal insulation, and durability makes them ideal for meeting the demanding requirements of the transportation industry.

Use in Recreational Vehicles (RVs)

For RVs, weight reduction is essential to improve fuel efficiency and maneuverability. Foam sandwich panels deliver an excellent strength-to-weight ratio, reducing the overall vehicle weight without compromising structural integrity. Additionally, the panels offer superior thermal insulation (high R-value), keeping indoor temperatures stable whether you’re on the road in summer or winter.

- Enhanced comfort with consistent temperature control

- Noise reduction from road and engine sounds, thanks to sandwich foam panelling

- Corrosion resistance extends the lifespan when exposed to outdoor elements

Shipping Containers and Transport Units

In shipping containers, maintaining internal conditions is vital, whether for refrigerated goods or dry freight. Foam sandwich panels serve as insulated sandwich panels that provide excellent thermal barriers, reducing energy costs to cool or heat the interiors.

- Durable exterior face sheets protect against impact, moisture, and weather

- Rigid foam cores such as polyurethane foam panels deliver excellent insulation and structural stability

- Enables custom sizes and thicknesses to fit different container designs or transport needs

Specialized Transportation Applications

Beyond RVs and containers, foam sandwich panels are also integral in:

- Mobile medical units, offering clean, insulated environments

- Food trucks and trailers, where hygiene and temperature control are critical

- Cold chain transport trailers, ensuring food and pharmaceuticals stay at safe temperatures

Why Foam Sandwich Panels Are Preferred for Transportation

- Lightweight but high strength for easier handling and transport

- Fire-resistant sandwich panels options available for added safety

- Moisture and corrosion resistant, ideal for harsh transportation environments

- Ability to be customized for size, shape, and insulation requirements by leading manufacturers like Shanghe

In the US market, where transport efficiency and sustainability are rising priorities, foam sandwich panels provide a smart, reliable solution for builders and fleet operators looking to enhance performance and save on energy costs.

Applications of Foam Sandwich Panels Specialty Uses Cleanrooms Modular Homes

Foam sandwich panels are perfect for specialty applications where high performance and reliability matter. Two prime examples are cleanrooms and modular homes, where controlled environments and lightweight, durable materials are crucial.

Cleanrooms

In cleanroom construction, maintaining strict air quality and temperature control is essential. Foam sandwich panels offer:

- Excellent thermal insulation, keeping temperature stable and reducing energy costs.

- Smooth, non-porous surfaces that are easy to clean and resist contamination.

- Fire-resistant core options like PIR panels, providing safety without compromising performance.

- Lightweight yet strong construction, enabling faster assembly and sturdy build quality.

These panels help meet stringent industry regulations in pharmaceuticals, electronics, and food processing by ensuring controlled environments.

Modular Homes

Modular homes benefit from foam sandwich panels due to their fast installation and excellent structural properties:

- Lightweight panels reduce transportation costs and make handling easier on-site.

- High strength-to-weight ratio supports durable, long-lasting structures.

- Superior thermal insulation boosts energy efficiency and comfort in all seasons.

- Moisture-resistant cores limit issues like mold and rot, enhancing home durability.

Using foam sandwich panels in modular homes speeds up construction timelines without sacrificing quality or energy savings.

Overall, the versatility of foam sandwich panels makes them invaluable in specialty uses like cleanrooms and modular homes, where performance, safety, and efficiency are top priorities. For these applications, choosing the right core material and panel type ensures you get the exact balance of insulation, fire resistance, and durability needed.

Applications of Foam Sandwich Panels Case Study Shanghe’s Panels in Specific Project Application

Shanghe’s foam sandwich panels have proven their value in a variety of real-world projects across the United States. Let’s take a deep dive into a specific application to see how these panels deliver on performance, durability, and cost-efficiency.

Project Overview

In a recent cold storage warehouse project in Texas, Shanghe supplied insulated sandwich panels featuring high-performance polyurethane foam cores with galvanized steel face sheets. This facility required superior thermal insulation, fire resistance, and quick installation to meet tight schedules and energy-saving goals.

Key Parameters of Shanghe’s Panels Used

- Core Material: Polyurethane (PUR) foam with an R-value of 7.2 per inch

- Face Sheets: 0.5 mm galvanized steel coating, corrosion-resistant

- Panel Thickness: 4 inches (customizable based on insulation needs)

- Fire Rating: Class A fire resistance certification

- Panel Width: 48 inches standard width, available in custom lengths

- Weight: Lightweight at approximately 3.6 lbs per square foot for easy handling and installation

Why Shanghe’s Foam Sandwich Panels Worked Perfectly

- Energy Efficiency: The high R-value foam core helped maintain consistent low temperatures inside the cold storage area, reducing energy costs dramatically.

- Durability: The galvanized steel face sheets provided robust protection against wear and moisture—a must in cold storage environments prone to condensation.

- Fast Installation: The panels were lightweight and easy to handle, allowing the construction team to finish walls and roof assemblies 20% faster than with traditional materials.

- Customization: Shanghe tailored panel sizes and thicknesses to fit design specs exactly, minimizing waste and simplifying the on-site workflow.

- Compliance: The panels met stringent fire safety and building code requirements, ensuring long-term safety and regulatory approval.

Results and Feedback

Thanks to Shanghe’s foam sandwich panels, the cold storage warehouse achieved:

- A 30% reduction in energy consumption compared to previous facilities

- Faster project completion without compromising quality

- Lower maintenance over the lifetime of the building thanks to the panels’ resilience

- Improved insulation performance, contributing to product safety and shelf life

The client praised Shanghe’s local support and timely delivery, highlighting the importance of working with a trusted US-based supplier familiar with market needs.

This case study shows how Shanghe foam sandwich panels are not just materials—you get a complete solution that fits tight schedules, budget demands, and performance targets typical of today’s US construction and industrial projects. Whether you’re tackling cold storage, industrial buildings, or modular construction, these panels deliver measurable benefits that stand the test of time.

Comparing Foam Sandwich Panels Which Type is Right for You PUR vs PIR Fire Resistance and Insulation

When choosing between PUR (Polyurethane) and PIR (Polyisocyanurate) foam sandwich panels, understanding their fire resistance and insulation performance is crucial for making the right choice for your project.

Fire Resistance

PIR panels offer superior fire resistance compared to PUR panels. This is because PIR foam has a modified chemical composition that forms a protective char when exposed to high temperatures. This char layer slows down flame spread and limits smoke production, making PIR sandwich panels a better option for applications requiring higher fire safety standards such as commercial buildings, warehouses, and public facilities.

In contrast, PUR sandwich panels, while still providing some fire resistance, burn more readily and produce more smoke and toxic gases under fire conditions. PUR panels commonly meet lower fire ratings and are better suited for projects with less stringent fire code requirements.

Insulation Performance

Both PUR and PIR foam sandwich panels deliver high thermal insulation, but there are subtle differences in their R-values (a measure of thermal resistance):

- PUR sandwich panels typically have an R-value around 6.0 to 7.0 per inch, making them excellent for standard insulation needs in residential and light commercial buildings.

- PIR panels usually offer slightly higher R-values, approximately 6.5 to 7.5 per inch, thanks to their denser molecular structure. This means PIR panels provide better thermal insulation per inch of thickness, helping improve energy efficiency in demanding environments.

of Key Differences

| Feature | PUR Sandwich Panels | PIR Sandwich Panels |

|---|

| Fire Resistance | Moderate fire resistance | High fire resistance with char formation |

| Thermal Insulation | Good R-value (~6.0–7.0/in) | Higher R-value (~6.5–7.5/in) |

| Smoke Emission | Higher smoke and toxic gases | Lower smoke production |

| Best Use Cases | Residential, light commercial | Industrial, commercial, high fire safety zones |

Which Panel to Choose

- Choose PIR foam sandwich panels if your project demands enhanced fire safety and better insulation performance, especially in commercial or industrial construction.

- Opt for PUR sandwich panels if you need a cost-effective insulation solution for residential buildings or less fire-sensitive applications.

Both panels improve energy efficiency and building comfort, but knowing these differences helps you pick the right foam sandwich panel tailored to your project’s safety and insulation needs.

Comparing Foam Sandwich Panels EPS vs XPS Cost vs Performance

When choosing between EPS foam panels and XPS sandwich panels, understanding the balance between cost and performance is key. Both types are popular in the U.S. market for insulated sandwich panels, but each has unique strengths that suit different project needs.

EPS Foam Panels Cost and Benefits

Expanded Polystyrene (EPS) is widely used because it offers a cost-effective solution with decent thermal insulation. EPS panels are generally more affordable than XPS, making them a favorite for large-scale construction projects where budget is critical.

- Lower price point reduces upfront costs

- Good thermal insulation (R-value) typically around 4.0 per inch

- Lightweight and easy to install

- Suitable for wall and roof panels in commercial and residential buildings

- Less moisture resistant than XPS; can absorb water if exposed

XPS Sandwich Panels Cost and Benefits

Extruded Polystyrene (XPS) panels usually come at a higher price but deliver enhanced performance features. XPS is preferred when long-term durability and moisture resistance are essential.

- Higher cost reflects superior quality and performance

- Better moisture resistance, making it ideal for environments with high humidity or potential exposure to water

- Slightly higher R-value (around 5.0 per inch) offers better insulation efficiency

- Stronger compressive strength lends itself well to demanding industrial or cold storage uses

- Provides excellent sound insulation and structural rigidity

Cost vs Performance

| Feature | EPS Foam Panels | XPS Sandwich Panels |

|---|

| Cost | More affordable | Higher upfront investment |

| Thermal Insulation | R-value ~4.0 per inch | R-value ~5.0 per inch |

| Moisture Resistance | Moderate | Excellent |

| Compressive Strength | Adequate for many uses | Superior for heavy-duty needs |

| Installation | Lightweight and easy | Slightly heavier but manageable |

| Best Use Cases | Cost-conscious projects, general construction | Moisture-prone environments, cold storage, industrial |

Which Panel Is Right for You

- Choose EPS foam sandwich panels if budget is a major factor and your project doesn’t involve high moisture exposure.

- Opt for XPS sandwich panels if you need long-lasting performance, better moisture resistance, and a bit more thermal efficiency for specialized or industrial-grade buildings.

At Shanghe, we offer a full range of foam sandwich panels tailored to your project’s price and performance needs. Our experts can help you find the right fit for your construction foam panels or cold storage projects, balancing cost with durability and efficiency.

Comparing Foam Sandwich Panels Which Type is Right for You Shanghe’s Expert Recommendations

Choosing the right foam sandwich panels for your project can be challenging given the variety of options like PUR panels, PIR panels, EPS panels, and XPS panels. At Shanghe, we focus on matching your specific needs with the best panel type to deliver optimal performance, cost-efficiency, and compliance with U.S. building codes.

Understand Your Project Needs First

- Thermal Insulation: For projects where high R-value is critical—like cold storage or energy-efficient buildings—PIR or PUR panels are recommended. They provide superior insulation with thinner profiles compared to EPS or XPS.

- Fire Resistance: Where fire safety is a major concern, especially in commercial or industrial buildings, PIR panels are preferred due to their enhanced fire-resistant properties, compliant with strict U.S. fire codes.

- Budget Constraints: If cost is a primary factor, EPS panels offer a great balance of affordability and insulation. For slightly higher budget and better moisture resistance, XPS panels are a solid step up.

Shanghe’s Expert Recommendations

- For residential and commercial construction, we advise polyurethane foam panels (PUR) because of their excellent thermal insulation and high strength-to-weight ratio.

- For industrial buildings, warehouses, or environments requiring strict fire performance, PIR sandwich panels are your best bet. They meet rigorous fire standards and maintain thermal performance over time.

- When working on cold storage or refrigeration projects, EPS foam panels provide effective insulation at an economical price point, but if moisture exposure is high, consider XPS sandwich panels for improved durability.

- For transportation uses like RVs or shipping containers, panels need to be lightweight yet durable. PUR and PIR panels fit this role well without adding unnecessary weight.

Customized Solutions from Shanghe

We offer custom panel thickness, facings, and core material options, helping you hit precise project specs whether you need roof panels, wall panels, or insulated facades. Our panels come with:

- Strict quality control

- Industry certifications

- Compliance with ASTM and U.S. building standards

Why Trust Shanghe for Your Foam Sandwich Panels

- Advanced manufacturing processes ensure consistent foam density and strong adhesion for long-lasting panels.

- We provide technical support and on-site consultation to guide you through material selection and installation.

- Competitive pricing combined with fast delivery services across the United States.

- Tested and proven in diverse U.S. applications from commercial buildings to specialty cleanrooms.

Choosing between PUR, PIR, EPS, and XPS panels depends heavily on your insulation needs, fire safety requirements, moisture exposure, and budget. Shanghe is here to help you make the right call by offering tailored recommendations informed by your project’s unique demands and local standards. Contact us to get expert advice on the perfect foam sandwich panels for your next build.

How to Choose a Foam Sandwich Panel Supplier Quality Customization Delivery

Choosing the right foam sandwich panel supplier is vital for getting reliable and efficient insulated sandwich panels that suit your project needs. Here are the key factors to consider when deciding on a supplier:

Quality and Certifications

Quality is non-negotiable when selecting foam sandwich panels for construction, cold storage, or industrial use. Make sure your supplier provides:

- Verified product certifications such as ASTM, ISO, FM approvals, or UL listings, which guarantee panel performance, fire resistance, and safety.

- Consistently tested thermal insulation R-values and structural strength data to match your specific requirements.

- Panels manufactured using advanced foam core technologies like polyurethane foam panels (PUR) or polyisocyanurate PIR sandwich panels, known for durability and insulation.

- Transparent quality control processes ensuring each batch meets strict standards.

Customization Options

Looking for panels that fit your project exactly? Customization can make all the difference. When evaluating suppliers, confirm they offer:

- Custom sizing for walls, roofs, or facades to minimize waste and improve installation efficiency.

- Variety in core materials (PUR, PIR, EPS, or XPS foam sandwich panels) matching your project’s thermal, fire, and budget needs.

- Flexible face sheet materials and finishes for aesthetics or added protection.

- Ability to handle specialty orders like cold storage panels or transportation-grade sandwich panel foam.

Delivery and Support

Reliable delivery and solid post-purchase support save time and headaches during your build. Choose a supplier who provides:

- Timely and transparent shipping schedules with tracking for your foam sandwich panel order.

- Expert customer support that can advise on panel selection, installation tips, and troubleshooting.

- Comprehensive warranty policies and easy claims for defective panels.

- After-sales services, including installation assistance or maintenance guidance.

By focusing on these factors—quality and certifications, customization options, and dependable delivery and customer support—you ensure your foam sandwich panels meet both performance standards and project timelines. This makes your building process smoother and guarantees long-lasting results.

How to Choose a Foam Sandwich Panel Supplier Why Shanghe Stands Out

When picking a foam sandwich panel supplier, it’s crucial to find a partner who combines quality, service, and value. Shanghe is a name that consistently stands out in the U.S. market for good reasons.

Global Reach Local Expertise

Shanghe offers the best of both worlds:

- Global sourcing and manufacturing capability ensure access to premium materials like polyurethane foam panels, PIR sandwich panels, EPS foam panels, and XPS sandwich panels.

- Their extensive international experience means they understand market trends and regulations.

- Plus, Shanghe provides local expertise through U.S.-based support teams, helping customers navigate project requirements and installation specifics smoothly.

Competitive Pricing Without Compromise

Shanghe leverages economies of scale and efficient production methods to offer high-quality foam sandwich panels at competitive prices. This means you get superior insulation panels without overspending. Their pricing structure is transparent, avoiding hidden fees or surprise costs — crucial for budgeting construction projects, cold storage setups, or transportation panel needs.

Customer Testimonials Prove Reliability

Many American companies trust Shanghe for their foam sandwich panel supply. Customer reviews highlight:

- Consistent product quality, with panels meeting or exceeding insulation and fire-resistance standards.

- Responsive service teams who provide timely answers and technical support.

- Customization options that help tailor foam sandwich panel solutions for unique applications like modular homes or industrial warehouses.

These testimonials back up Shanghe’s reputation as a dependable, trusted supplier in the foam sandwich panel market.

By choosing Shanghe, you benefit from a supplier who understands U.S. construction needs, offers versatile insulated sandwich panels, and supports your project every step of the way — making them a smart choice for your foam sandwich panel needs.

Installation Best Practices for Foam Sandwich Panels

Installing foam sandwich panels correctly is crucial to ensure they deliver their full benefits like thermal insulation, fire resistance, and structural strength. Whether you’re working with polyurethane foam panels, PIR sandwich panels, or EPS foam panels, following best practices will boost performance and extend panel life.

Plan and Prepare the Site

- Inspect the surface: Make sure the substrate or framing is clean, even, and structurally sound to support the panels without flexing.

- Check panel specifications: Confirm panel sizes, thicknesses, and types align with your project requirements. This prevents mismatches during installation.

- Schedule installation during dry weather when possible. Moisture can affect adhesives and panel edges.

Handle with Care

- Use proper lifting equipment like suction lifters or forklifts to move panels.

- Avoid dropping or sliding panels on rough surfaces to prevent damage to the face sheets or foam core.

- Store panels flat, off the ground, and covered to prevent warping and water absorption.

Correct Fastening Techniques

- Use appropriate fasteners for the panel’s face sheet material (metal, plywood, or other).

- Maintain manufacturer-recommended spacing between fasteners to avoid compression or deformation.

- Seal all fastener penetrations properly to prevent thermal bridging and moisture ingress.

Panel Joint Installation

- Overlap panels or use tongue-and-groove edges where applicable to form tight joints.

- Seal joints with compatible weatherproofing tapes or sealants to maintain insulation integrity.

- Follow specific instructions for installing corner panels and end caps to minimize thermal leaks and ensure airtightness.

Thermal and Moisture Considerations

- Install vapor barriers or membranes as prescribed, especially for cold storage panels or humid environments.

- Ensure flashing and drip edges are integrated to guide water away from joints and fasteners.

Final Inspection and Testing

- Check for gaps, misalignments, or damaged areas after installation.

- Perform water spray tests or infrared thermal imaging (if possible) to confirm airtightness and insulation continuity.

Installing foam sandwich panels right means fewer maintenance issues and long-lasting performance for applications ranging from roof sandwich panels to cold storage and industrial buildings. For more detailed installation guidance, consider Shanghe’s installation services and support, which can help make sure your project goes smoothly from start to finish.

Maintaining Your Foam Sandwich Panels for Longevity

Proper maintenance is essential to maximize the lifespan and performance of your foam sandwich panels. These insulated sandwich panels, whether used in walls, roofs, or refrigerated units, require regular care to keep their thermal insulation and structural integrity intact.

Regular Inspections

- Check for surface damage such as dents, scratches, or punctures in the face sheets. Even minor damage can compromise insulation and allow moisture infiltration.

- Inspect panel joints and seams for any signs of gaps, loose fittings, or sealant deterioration. Tight joints help maintain airtightness and energy efficiency.

- Look for moisture buildup or mold, especially in humid environments or cold storage panels, to prevent corrosion or panel degradation.

Cleaning Guidelines

- Use a soft cloth or sponge with mild detergent to clean panel surfaces. Avoid abrasive cleaners or harsh chemicals that can damage the protective finish of the sandwich panel foam or face sheets.

- Rinse thoroughly with clean water and dry to prevent water spots or mold.

- Regular cleaning helps preserve the panel’s appearance and fire-resistant properties.

Managing Repairs and Replacements

- Promptly address any damage to the face sheets or core materials. Your foam sandwich panel supplier can provide repair kits or replacement panels if needed to maintain insulation and fire resistance.

- For fire-resistant sandwich panels or those with specialized cores like PUR or PIR, always use repair materials compatible with the original panel to maintain performance.

Environmental Considerations

- Avoid prolonged exposure to direct UV light unless panels have UV protection coatings.

- Protect panels from chemical spills or extreme temperature fluctuations that may impact foam core stability or face sheet adhesion.

of Maintenance Best Practices

- Regularly inspect for damage and moisture

- Clean gently with mild detergent and water

- Seal and repair joints or damaged areas quickly

- Use compatible repair materials matching panel types (PUR, PIR, EPS, or XPS)

- Protect panels from harsh environmental conditions

By following these simple but effective maintenance tips, your foam sandwich panels will deliver long-lasting thermal insulation, fire resistance, and structural strength, ensuring excellent return on investment.

For more on installation best practices that complement panel care, visit our detailed guide on metal insulated sandwich panel installation.

Installation and Maintenance Tips Shanghe’s Support for Foam Sandwich Panel Installation and Aftercare

At Shanghe, we know that the success of your project depends not just on the quality of foam sandwich panels, but also on precise installation and ongoing care. Our team offers comprehensive support to ensure your insulated sandwich panels perform at their best from day one.

Expert Guidance for Smooth Installation

We provide detailed installation instructions tailored to each type of foam sandwich panel, including polyurethane foam panels, PIR sandwich panels, EPS foam panels, and XPS sandwich panels. Our technical support covers:

- Site preparation advice to ensure a clean, even surface

- Panel handling tips to prevent damage during transport and fitting

- Correct fastening and sealing methods to maintain thermal insulation and fire resistance

- Guidance on compatible accessories like joints and fixing systems for walls, roofs, and facades

This support helps avoid common problems such as panel warping, thermal bridging, or compromised fire performance, keeping your construction foam panels fully effective over time.

Maintenance Advice for Longevity

To get the most out of your foam sandwich panels, regular maintenance is key. Shanghe provides recommendations focused on:

- Routine inspections of panel surfaces for signs of damage, moisture intrusion, or wear

- Safe cleaning techniques that protect the panel’s outer face sheets without degrading the core foam

- Timely repairs of any sealants or joints to maintain sound insulation and durability

- Preventive measures against environmental factors common in the U.S., like UV exposure and temperature fluctuations

Keeping up with these practices ensures your thermal insulation panels continue to deliver energy efficiency and structural integrity.

Aftercare Support From Shanghe

We offer continuous after-sales service for our foam sandwich panel products, including:

- Access to replacement parts and compatible accessories

- Technical support for troubleshooting installation or maintenance issues

- Customized advice for specific project needs or unusual environmental conditions

- Fast response times and reliable shipping across the U.S.

Choosing Shanghe means you’re backed by a partner dedicated to helping you maximize the value of your foam sandwich panels throughout their lifespan.

For more details on our foam sandwich panels and support services, check out our polyurethane wall panels and sandwich panels for walls to find solutions suited for your project.

Lifespan of Foam Sandwich Panels

When you’re investing in foam sandwich panels, knowing how long they last is essential for planning and cost management. Typically, these insulated sandwich panels have a lifespan of 25 to 30 years, sometimes even longer with proper care and maintenance.

Factors Influencing Lifespan

- Quality of Materials: Panels made with high-grade foam cores like PUR (polyurethane) or PIR (polyisocyanurate) and strong face sheets tend to last longer.

- Installation: Correct installation impacts durability significantly. Poor installation can lead to moisture infiltration, reducing panel life.

- Exposure Conditions: Panels exposed to harsh weather, UV rays, or chemical environments might experience faster aging compared to those in controlled conditions.

- Maintenance: Regular inspection and upkeep prevent issues such as surface damage or core degradation, effectively extending panel life.

Why Foam Sandwich Panels Last Long

- Durable Core Materials: Foam cores like PUR, PIR, EPS, and XPS resist compression, moisture, and thermal degradation.

- Protective Face Sheets: Steel, aluminum, or fiberglass face sheets shield the core, adding mechanical strength and weather resistance.

- Thermal Stability: These panels maintain their insulation properties over time, preserving energy efficiency.

You can expect foam sandwich panels to provide reliable performance for around three decades. For commercial and residential construction, this makes them a long-term, cost-effective solution. To maximize lifespan, opt for quality products with appropriate certifications, ensure professional installation, and follow routine maintenance schedules.

For more details about durable foam sandwich panels and options that fit your project needs, check out our Prefabricated Sandwich Panel page.

Are Foam Sandwich Panels Fire Resistant

When it comes to fire resistance, foam sandwich panels vary based on the type of foam core and outer materials used. Not all foam panels are equally fire-resistant, so choosing the right one is crucial for safety and building code compliance.

Foam Core Fire Resistance Overview

- Polyurethane (PUR) panels offer good insulation but have moderate fire resistance. They can be treated with fire retardants but tend to burn faster than other foam types if exposed directly to flame.

- Polyisocyanurate (PIR) panels are known for better fire resistance compared to PUR. PIR foam forms a char layer when exposed to fire, slowing combustion and lowering heat release. This makes PIR sandwich panels a preferred choice where fire safety is a priority.

- Expanded Polystyrene (EPS) panels generally have poor fire resistance without treatment. They burn quickly and release dense smoke, so special fire-retardant additives or protective facings are required.

- Extruded Polystyrene (XPS) panels show slightly better fire performance than EPS but still need fire retardant treatments or coatings to meet fire safety standards.

Face Sheets Impact on Fire Resistance

The face sheets—usually steel, aluminum, or fiber-reinforced plastic—also play a vital role. Metal face sheets can help slow fire spread by acting as a barrier, while certain coated or treated facings add extra fire protection.

Fire Ratings and Compliance

Most foam sandwich panels should meet national fire safety ratings such as ASTM E84 (Surface Burning Characteristics), NFPA standards, or local building codes in the U.S. When selecting panels, check for:

- Class A or Class 1 fire rating for construction panels used in walls and roofs.

- Certification verifying compliance with fire-resistance standards.

- Additional fire-retardant treatments or facings depending on application.

- PIR foam sandwich panels offer the best fire resistance among foam cores.

- PUR panels provide moderate fire protection with possible treatment.

- EPS and XPS panels need fire-retardant additives and careful handling.

- Metal or treated face sheets enhance overall fire safety.

- Always choose panels with standard fire certifications for your specific project.

At Shanghe, we provide foam sandwich panels tested and certified to meet strict fire resistance requirements, ensuring safety without compromising insulation and durability.

How Foam Sandwich Panels Compare to Traditional Materials

When it comes to choosing building materials, foam sandwich panels stand out as a modern alternative to traditional options like concrete, brick, or timber. Here’s how they stack up across key factors that matter most in construction and insulation:

Superior Insulation Performance

Foam sandwich panels provide excellent thermal insulation thanks to their rigid foam cores such as polyurethane (PUR) and polyisocyanurate (PIR). This means buildings stay warmer in winter and cooler in summer, reducing energy costs significantly. Compared to traditional materials that rely heavily on separate insulation layers, foam panels deliver better R-values within a thinner profile.

Lightweight Yet Strong

Unlike heavy concrete or brick walls, foam sandwich panels are lightweight but offer a high strength-to-weight ratio. This makes installation faster and easier, lowers transportation costs, and puts less stress on structural frameworks. Yet, they maintain robustness for long-term durability.

Enhanced Fire Resistance

Certain types like PIR panels offer improved fire resistance compared to wood and some traditional insulation. While foam panels may vary in fire ratings, they often include fire-retardant additives that meet stringent codes, making them safer choices for many construction foam panels applications.

Moisture Resistance and Durability

Traditional materials like wood are susceptible to rot, mold, or warping over time. Foam sandwich panels, especially those with closed-cell core foams like extruded polystyrene (XPS), resist moisture, which extends panel life and reduces maintenance needs.

Noise Reduction

The composite structure of foam sandwich panels provides better sound insulation than many conventional walls, creating quieter indoor environments—an important factor for offices, homes, and hospitals.

Customization and Versatility

Foam sandwich panels are easily customized in size, thickness, and face material to fit diverse uses, from cold storage panels to roofing and walls. Traditional materials often require multiple steps and products to achieve similar finishes.

Cost Efficiency Over Time

While the upfront cost of foam sandwich panels may be slightly higher than some traditional materials, the energy savings, reduced labor, and lower maintenance costs balance the budget over the building’s lifespan.

In , foam sandwich panels combine better insulation, lighter weight, durability, and design flexibility compared to traditional materials like brick, concrete, or timber. For U.S. projects focused on energy efficiency, speed, and quality, foam sandwich panels offer a clear advantage as modern thermal insulation panels and structural components.

FAQs About Foam Sandwich Panels

Can Shanghe Customize Panel Sizes and Designs

Yes, Shanghe offers fully customizable foam sandwich panels tailored to your specific project needs. Whether you require unique dimensions, specific core materials like polyurethane foam panels or PIR sandwich panels, or varying face sheets, Shanghe can deliver the right solution.

Customization Options Include

- Panel Sizes: Length, width, and thickness can be adjusted to fit any building requirement—from small modular units to large industrial walls and roofing panels.

- Core Material Selection: Choose from PUR (polyurethane), PIR (polyisocyanurate), EPS (expanded polystyrene), or XPS (extruded polystyrene) foam cores depending on your insulation and fire-resistance preferences.

- Face Sheets: Options for metal, aluminum, galvanized steel, or other composite materials based on durability and aesthetic needs.

- Surface Finishes: Matte, glossy, textured finishes, or coatings for enhanced weather resistance and appearance.

- Additional Features: Integration of fire retardants, vapor barriers, or anti-microbial treatments for specialized applications like cold storage or cleanrooms.

Why Customization Matters

- Optimized Performance: Get the exact R-value and fire-resistance rating required for your climate and code compliance.

- Cost Efficiency: Avoid overpaying for standard sizes by matching panel dimensions precisely to your project.

- Ease of Installation: Panels tailored to fit your structure reduce waste and speed up assembly.

- Aesthetic Flexibility: Custom face sheets and finishes support your design vision, whether for commercial facades or residential modular homes.

How to Proceed with Custom Orders

- Consult with Shanghe’s expert team to discuss your project specifications and technical requirements.

- Provide detailed measurements and performance criteria.

- Receive a tailored quote and design proposal.

- Approve prototypes or samples, if needed, before full production.

By choosing Shanghe’s customizable foam sandwich panels, you ensure your project benefits from high-quality, precisely engineered insulated sandwich panels that meet U.S. building standards and your unique application needs.

For personalized assistance and quotes, contact Shanghe directly to explore your options.