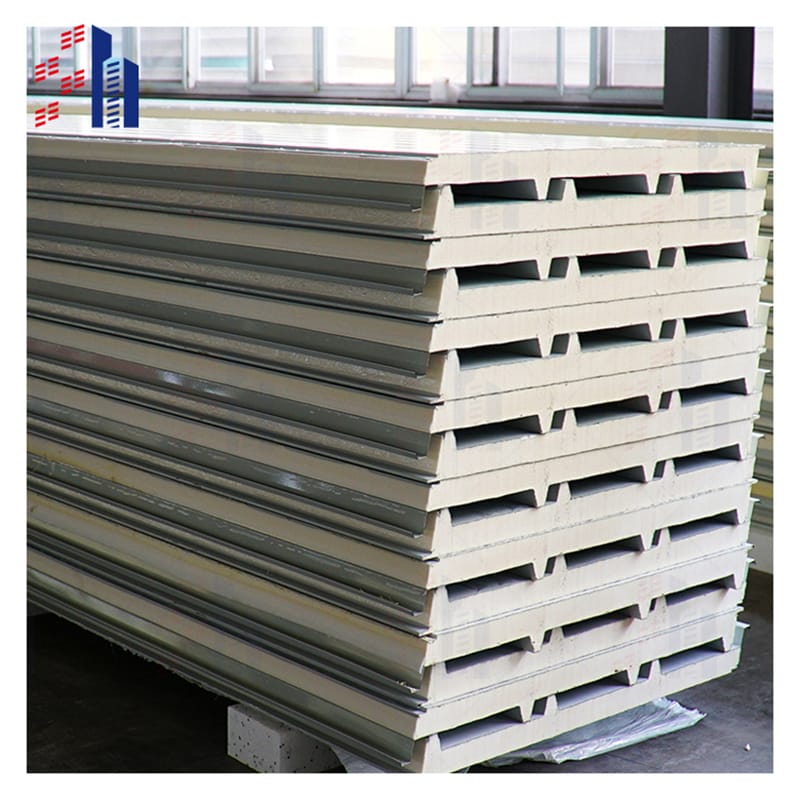

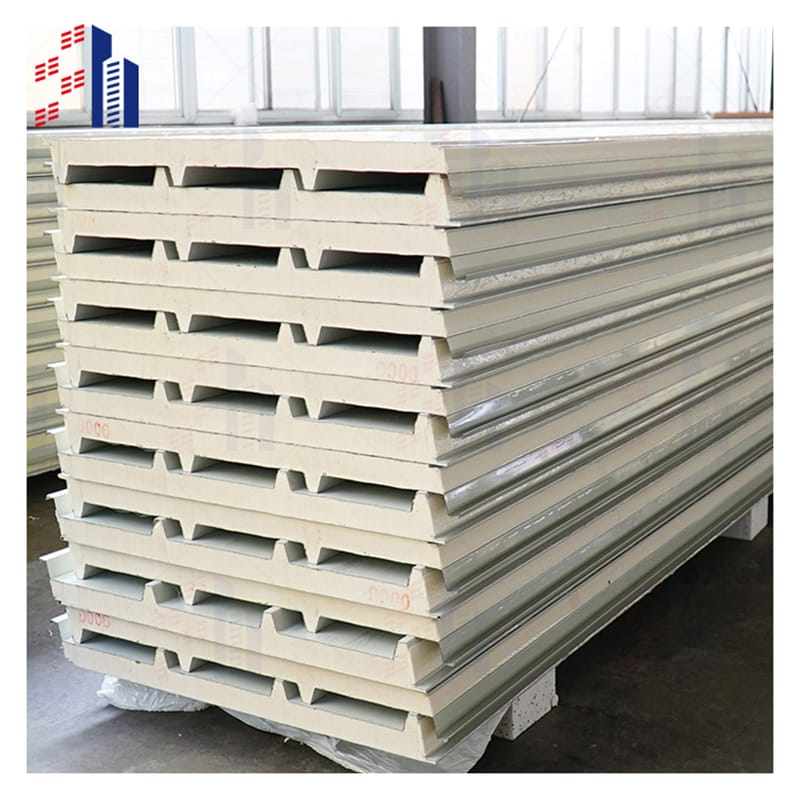

Composite Foam Sandwich Panels EPS: Why They’re the Best Insulation Solution for Your Building Projects

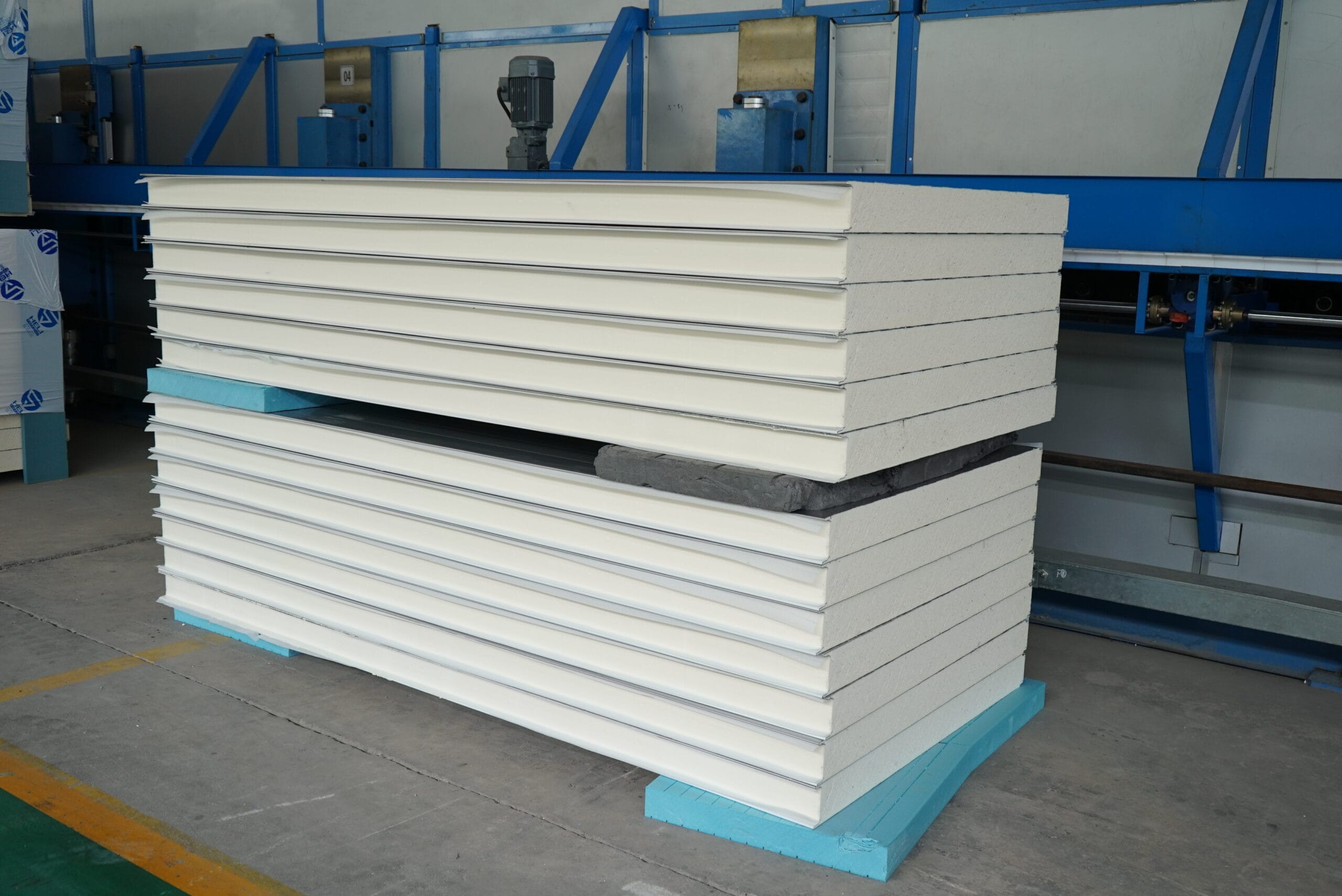

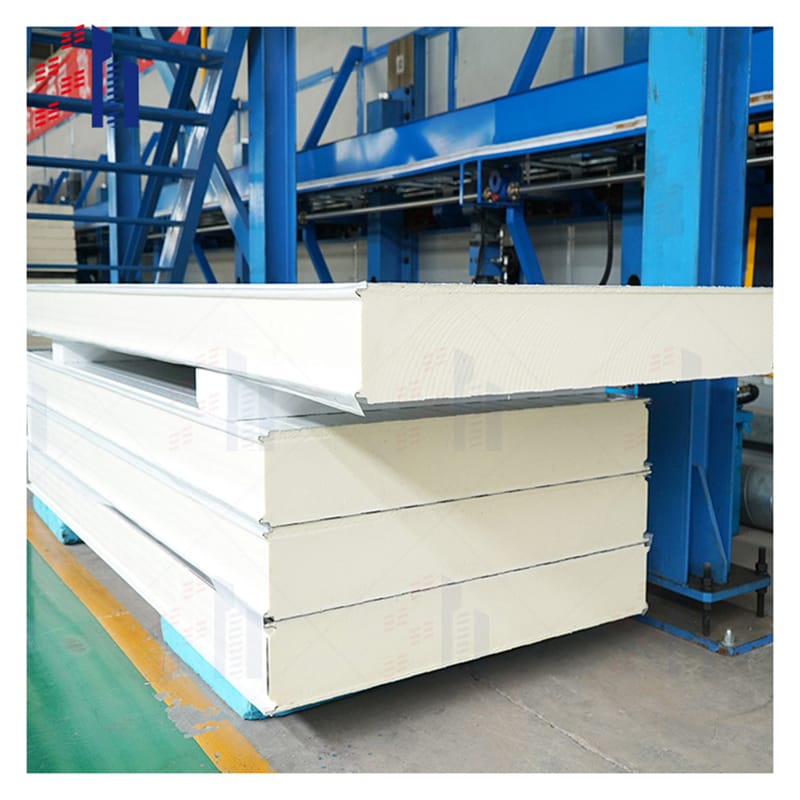

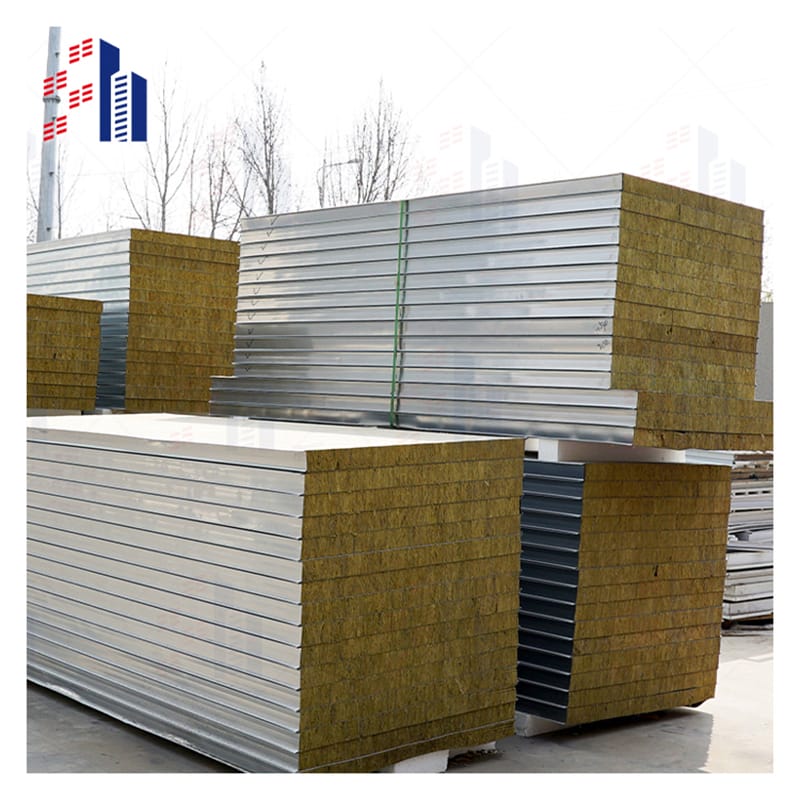

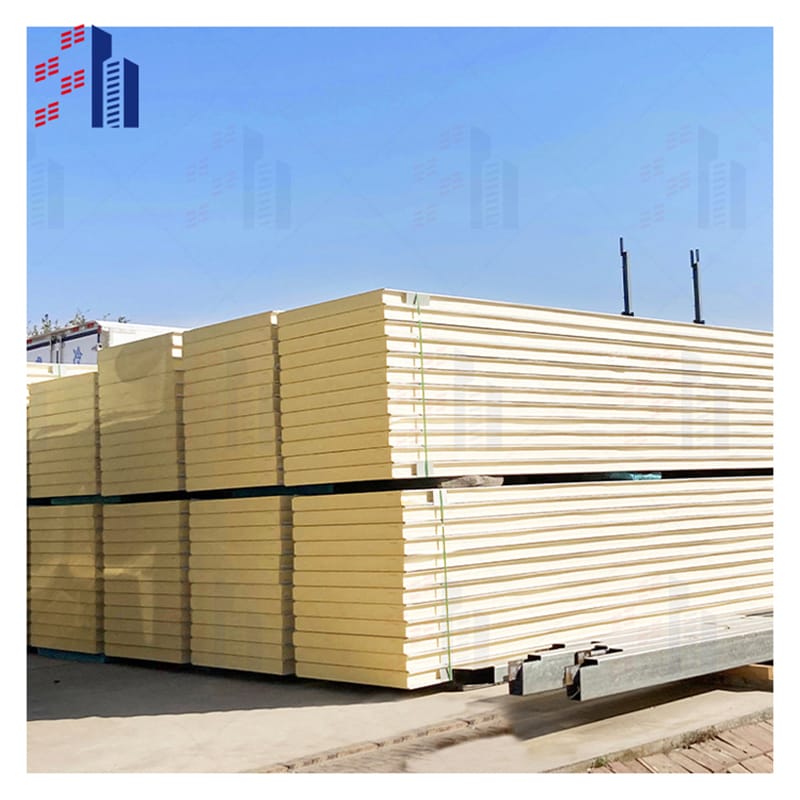

If you’re tired of dealing with poor insulation, high energy costs, and weak structural support in your construction projects, composite foam sandwich panels EPS might just be your answer. These panels are lightweight, super durable, and provide unbeatable thermal insulation—saving you money on heating and cooling while keeping buildings strong. EPS (Expanded Polystyrene) is the secret sauce here, offering high resistance to moisture and mold, which is a huge deal if you’ve ever had to deal with rotting or inefficient walls.

What makes these panels stand out? Well, they’re LEED-Certified in many cases, meaning they meet strict energy efficiency standards. Plus, they’re a favorite in commercial and industrial builds because they cut labor costs—no need for extra framing or insulation layers. And let’s be real, who doesn’t love a product that speeds up construction without cutting corners? Whether you’re working on cold storage, warehouses, or even residential projects, EPS-based composite panels deliver performance without the headaches.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details (Imperial Units) | Why It Matters |

| Core Material | PIR (Polyiso) / PUR / EPS | PIR = highest R-value (R-8.5/in), PUR = fire-resistant, EPS = budget-friendly |

| Thickness | 2″ to 8″ (custom up to 12″) | Thicker panels = better insulation for sub-zero freezers |

| R-Value | R-16 to R-40 (varies by core) | Beats fiberglass (R-3.1/in) – slashes energy bills |

| Metal Gauge | 22-18 (0.8mm to 1.2mm) | 18-gauge = heavy-duty for high-traffic warehouses |

| Fire Rating | Class A (ASTM E84) / FM Approved | Meets insurance requirements for industrial facilities |

| Temp Range | -40°F to +200°F (-40°C to 93°C) | Handles blast freezers to heated processing rooms |

| Panel Width | 36″ or 42″ (standard) | Wider panels = fewer seams, faster install |

| Custom Lengths | Up to 50′ (no splice needed) | Eliminates weak points in long runs |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Composite Foam Sandwich Panels Eps |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Composite Foam Sandwich Panels: How They Slash Costs & Boost Durability in Construction

You know what’s frustrating? Spending a fortune on traditional building materials that crack, warp, or lose efficiency over time. That’s where composite foam sandwich panels come in—they’re the game-changer you’ve been waiting for. These panels combine a rigid foam core (like EPS, PU, or XPS) with strong outer layers, usually metal or fiberglass, creating a lightweight yet ultra-durable solution.

Here’s the kicker: they’re way faster to install than conventional materials. No more waiting weeks for multiple layers of insulation and cladding—just one panel does it all. And because they resist moisture, fire, and pests (thanks to advanced manufacturing techniques), they last decades longer than traditional builds. Big names like Dow Chemical and Kingspan have backed this tech for years, and if you’re still on the fence, just check out how many warehouses and airports now rely on them. Bottom line? Fewer repairs, lower bills, and happier clients.

The Secret to Smarter, Safer Electronics & Aerospace Designs

Ever had an electronic device overheat or a sensitive component fail because of poor heat dissipation? That’s exactly why engineers are turning to conductive foam—a lightweight, flexible material that manages heat and static like a pro. Unlike traditional insulation, this stuff doesn’t just sit there; it actively redirects heat away from critical parts, preventing meltdowns and extending product life.

From NASA’s spacecraft to your latest smartphone, conductive foam is everywhere because it works. It’s often made with carbon or metal additives, giving it that extra conductivity without adding bulk. And for industries like aerospace or medical devices, where safety is non-negotiable, this material is a lifesaver—literally. So if you’re tired of playing trial-and-error with thermal management, it’s time to switch to foam that pulls its weight.

EPP Foam Molding: Why It’s Revolutionizing Automotive & Packaging Industries

Let’s face it—traditional packaging and car interiors are either too fragile or way too heavy. Enter EPP foam molding, the lightweight, shock-absorbing hero you didn’t know you needed. Expanded Polypropylene (EPP) is that rare material that’s both tough and cushiony, perfect for everything from BMW door panels to eco-friendly packaging that survives rough shipping.

Why’s it so good? Well, it bounces back after impact (unlike Styrofoam, which just cracks), and it’s 100% recyclable—a big deal in today’s green-focused market. Companies like Toyota and Amazon have already switched to EPP for its cost efficiency and durability. So whether you’re designing car parts or shipping delicate gear, this foam cuts waste and damage claims like nothing else.

Plastic Foam: Busting Myths & Choosing the Right Type for Your Project

Plastic foam gets a bad rap—some say it’s weak, others complain it’s not eco-friendly. But here’s the truth: not all plastic foams are created equal, and picking the right one can make or break your project. EPS (for insulation), EPP (for impact resistance), and PU (for structural strength) all have unique perks.

Take LEED-certified buildings—they often use EPS because it’s energy-efficient and recyclable. Meanwhile, surfboards and flotation devices rely on PU foam for its rigidity. And with new bio-based foams hitting the market, sustainability is no longer an issue. The key? Know your needs. Insulation? Go EPS. Need something that takes a beating? EPP’s your guy. Stop settling for one-size-fits-all solutions and get foam that actually works for you.

Plastic Foaming 101: How It Saves Time & Money in Manufacturing

If you’re still molding parts the old-school way, you’re wasting time and material. Plastic foaming—where gas expands plastic to create lightweight, strong structures—is the shortcut smart manufacturers are using. This process cuts material use by up to 40% (yes, really) while maintaining strength, which means lower shipping costs and faster production times.

Companies like BASF and SABIC have perfected foaming techniques for everything from car bumpers to furniture. And because foamed parts often need less assembly (no screws or extra supports), you’re looking at fewer production steps and happier engineers. So if efficiency is your goal, it’s time to foam—or get left behind.