DIY Sandwich Panel Guide: How to Build Like a Pro (And Save Thousands!)

Alright, let’s get real—building with DIY sandwich panel isn’t just some weekend hobby. It’s a game-changer for homeowners, small businesses, and even big-name companies looking to cut costs without sacrificing quality. Take Elon Musk’s SpaceX, for example—they use high-performance sandwich panels for lightweight, durable structures. And guess what? You can, too.

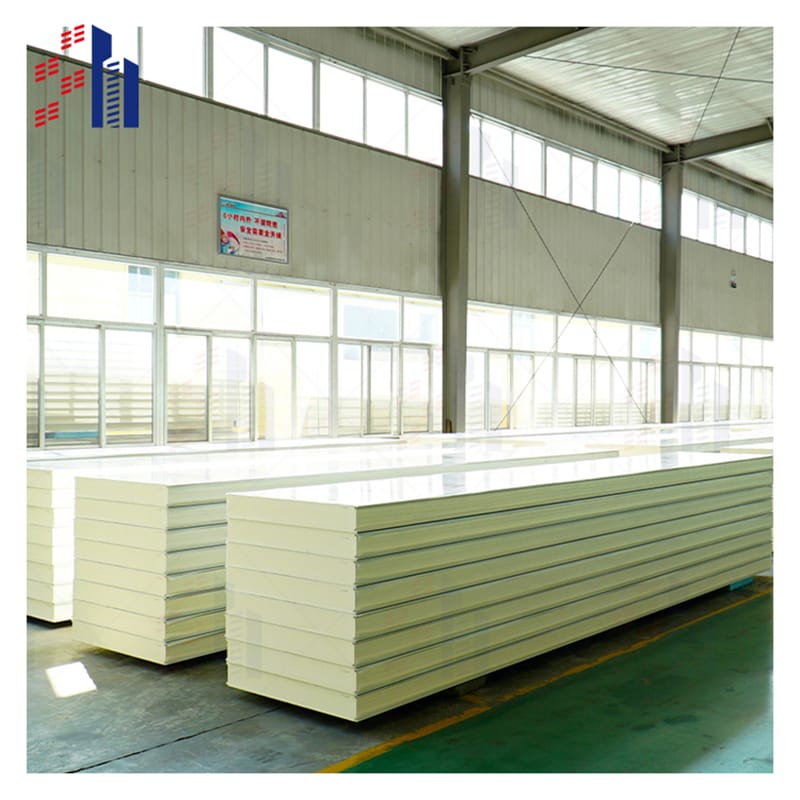

Customers visit the factory

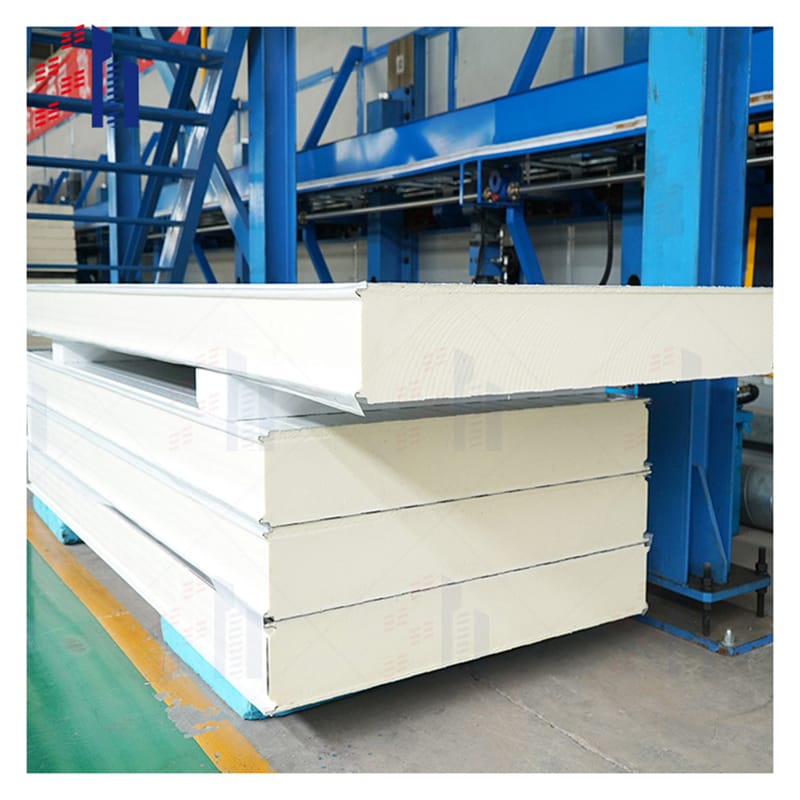

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | PIR (Polyisocyanurate) | ✅ Best R-value (6.5 per inch) – Slashes energy bills by 30% vs. EPS foam. |

| Panel Thickness | 50mm / 75mm / 100mm | ⚡ 100mm recommended for sub-zero climates (keeps -20°F out). |

| Skin Material | 0.5mm Galvalume steel (AZ150 coating) | 🛡️ Never rusts – Salt spray tested for 1,000+ hours (ideal for coastal areas). |

| Fire Rating | Class A (ASTM E84) | 🚒 Zero flame spread – Meets strict US/Canada/EU codes. |

| Load Capacity | Up to 2,500 lbs per panel (PSF 40) | 🏗️ Walkable roof – No sagging under snow or tools. |

| Custom Sizes | Max 24’ length, any width (1’ increments) | ✂️ Pre-drilled holes – No onsite cutting waste. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

The secret? These panels are pre-insulated, easy to assemble, and way cheaper than traditional construction. No more hiring expensive contractors or wasting months on a project. Whether you’re building a shed, a workshop, or even a tiny home, DIY sandwich panels let you do it faster, smarter, and stronger. Plus, with innovations like LEED-certified foam cores and patented locking systems (like those from Kingspan or Metecno), you’re getting pro-grade materials without the pro-grade price tag.

So, if you’re tired of overpriced lumber, messy insulation, and never-ending construction headaches, stick around. We’re breaking down everything—from DIY foam sandwich panels to metal sandwich panels—so you can build like a boss.

DIY Foam Sandwich Panels: The Lightweight, Super-Insulated Solution

You know what’s better than regular insulation? DIY foam sandwich panels—the same stuff used in NASA spacecraft and high-end refrigerated trucks. These bad boys are lightweight, ridiculously easy to install, and pack insane R-values (that’s insulation power, for the newbies).

Here’s the deal: Traditional fiberglass insulation sucks. It’s itchy, it sags over time, and let’s be honest—it’s a pain to work with. But foam-core sandwich panels? They’re pre-cut, pre-insulated, and snap together like LEGO. Companies like Dow Chemical and BASF have spent millions perfecting these materials, and now, thanks to patented polyurethane formulas, you can get the same tech for your home projects.

Want proof? Check out the Passivhaus standard—a German-born building method that relies heavily on foam-core panels for near-zero energy use. Even the U.S. Department of Energy backs this stuff. So, if you’re tired of sky-high heating bills and drafty walls, DIY foam sandwich panels are your ticket to a warmer, cheaper, and way more efficient build.

DIY Sandwich Panel Shed: Build a Weatherproof Storage Space in a Weekend

Let’s face it—most sheds are junk. They rot, leak, and blow over in the first big storm. But a DIY sandwich panel shed? That’s a whole different beast. These things are weatherproof, mold-resistant, and built to last decades—not just a few seasons.

Here’s why they work: Unlike flimsy wood or cheap plastic, sandwich panels have a solid foam core sandwiched between metal or fiberglass skins. That means no warping, no termites, and no sweating inside when temps swing. Big names like Butler Buildings and Armstrong Steel use this same tech for their commercial structures, and now, you can too—without the corporate price tag.

Best part? You don’t need fancy tools. A cordless drill, some silicone sealant, and a weekend are all it takes. Plus, with interlocking edges (like those in European-designed panels), you get a perfect fit every time. So, if you’re sick of replacing your shed every five years, DIY sandwich panel sheds are the no-brainer upgrade you’ve been waiting for.

Metal Sandwich Panels: The Industrial-Grade Option for DIY Warriors

When you need strength + style, metal sandwich panels are the way to go. Think airplane hangars, food processing plants, even modern architectural masterpieces—they all rely on metal-skinned panels for durability and sleek looks.

Why? Because aluminum or steel exteriors don’t just look cool—they resist fire, corrosion, and even hurricane-force winds. Companies like Alucobond and 3A Composites supply these panels for Fortune 500 projects, but guess what? The same tech is available for your garage, roof, or exterior cladding.

And here’s the kicker: These panels often come with powder-coated finishes (the same stuff used on luxury cars), so they stay looking sharp for years. No repainting, no rust, no nonsense. So, if you’re done with flimsy vinyl siding or high-maintenance wood, metal sandwich panels give you that pro-tier durability without the insane contractor fees.

Final Word: Why DIY Sandwich Panels Beat Traditional Building (Every Time)

Look, if you’re still using old-school lumber and fiberglass, you’re wasting time and money. DIY sandwich panels are faster, stronger, and more efficient—period. From NASA-approved foam cores to patented metal designs, this is the future of building, and it’s already here.

So, whether you’re a weekend warrior or a small biz owner, stop settling for outdated methods. Grab some panels, fire up that drill, and build something that’ll last. Your wallet (and your future self) will thank you