What Are EPS Foam Sandwich Panels

EPS foam sandwich panels, also known as EPS insulated wall panels or polystyrene foam panels, are advanced construction materials designed for superior thermal insulation combined with structural strength. These panels consist of a core of expanded polystyrene (EPS) foam securely bonded between two durable outer layers, typically made from galvanized steel or aluminum sheets. This combination creates a lightweight yet robust panel that excels in insulation and protection.

Customers visit the factory

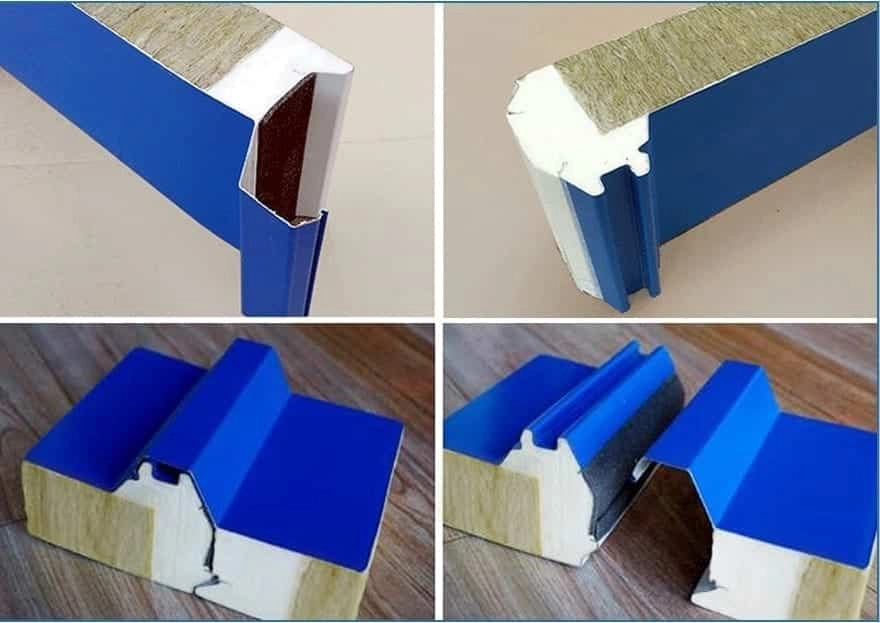

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Manufacturing Process of EPS Foam Sandwich Panels

The manufacturing of EPS foam sandwich panels involves several precise steps to ensure quality and performance:

- EPS Foam Core Production: Expanded polystyrene beads are expanded through a controlled steam process to form a dense, rigid foam block with excellent insulating properties.

- Cutting and Shaping: The EPS foam blocks are cut into uniform panels that meet specific size and thickness requirements.

- Surface Material Preparation: Outer layers, often galvanized steel or aluminum, are treated and prepared to ensure a strong bond and corrosion resistance.

- Lamination and Bonding: The EPS core is sandwiched between the prepared surface sheets and pressed together using heat and pressure, ensuring a seamless, high-strength bond.

- Quality Inspection: Finished panels undergo strict checks for thermal performance, dimensional accuracy, and bonding integrity.

Shanghe’s Unique Features in EPS Foam Sandwich Panels

What sets Shanghe EPS foam sandwich panels apart is their emphasis on innovation, durability, and customer-specific solutions. Key features include:

- High-Quality EPS Core with optimized density that balances lightweight convenience with excellent thermal insulation and fire resistance.

- Customizable Panel Sizes and Thicknesses to fit a wide range of applications from residential to industrial settings.

- Advanced Surface Materials, including galvanized steel sheets treated for anti-corrosion, ensuring longer service life even in harsh environments.

- Strict Quality Control Standards aligned with international certifications, which guarantee safety, durability, and performance.

- Eco-Friendly Production Methods that minimize environmental impact while delivering energy-efficient materials tailored for the U.S. market.

Shanghe EPS foam sandwich panels combine the best of lightweight construction materials and thermal insulation panels, making them an ideal choice for modern building needs.

Key Benefits of Shanghe EPS Foam Sandwich Panels

Shanghe EPS foam sandwich panels offer a smart, reliable choice for various building needs across the US. Here’s why they stand out:

Superior Thermal Insulation

Our EPS sandwich panels feature excellent thermal insulation thanks to the high-quality expanded polystyrene foam core. This reduces heat transfer, keeping interiors warm in winter and cool in summer. As a result, you save on energy bills while maintaining comfortable spaces year-round. These insulated wall panels are ideal for residential, commercial, and industrial projects that require efficient temperature control.

Lightweight and Durable

Shanghe EPS foam sandwich panels combine lightweight construction materials with strength. They’re easy to handle and install, which speeds up your project timeline and lowers labor costs. Despite their light weight, they are tough and provide long-lasting durability, resisting deformation, cracking, and impact damage.

Fire Resistance

Safety matters, especially in building materials. Our panels feature fire-resistant sandwich panel technology, meeting strict fire rating standards. The EPS core is treated with fire retardants, helping slow flame spread and reduce smoke production, which is crucial for commercial buildings, cold storage, and prefabricated structures seeking compliance with US fire codes.

Sound Insulation

Beyond thermal benefits, these EPS foam panels deliver excellent soundproofing performance. They reduce noise pollution from outside and between rooms, making them perfect for industrial enclosures, office spaces, and transportation units where noise control is essential.

Eco-Friendly

Shanghe EPS foam sandwich panels are made with environmentally friendly materials that are reusable and recyclable. The panels help improve energy efficiency, lowering carbon footprints for your construction projects. Choosing these panels supports sustainable building practices while meeting modern environmental standards.

Cost Effective

Compared to other insulated wall panels like PU or rockwool, our EPS panels offer a great balance of cost and performance. Their ease of installation, longevity, and maintenance savings contribute to lower overall project costs. For budget-conscious projects without sacrificing quality, Shanghe panels deliver strong value.

In short, Shanghe EPS foam sandwich panels provide a winning combination of thermal efficiency, durability, fire and sound resistance, eco-friendliness, and cost savings—a versatile solution tailored to the needs of US builders and developers.

Applications of Shanghe EPS Foam Sandwich Panels

Shanghe EPS foam sandwich panels are incredibly versatile, making them a popular choice across multiple industries in the United States. Their combination of thermal insulation, lightweight design, and durability allows them to fit perfectly in diverse settings. Here’s where you’ll often find these insulated wall panels delivering top performance:

Construction

In building construction, Shanghe EPS foam sandwich panels are widely used for external and internal walls, roofing, and ceilings. They offer excellent thermal insulation, helping reduce heating and cooling costs while providing a lightweight construction material that speeds up installation. Builders appreciate their strength and moisture resistance, making them ideal for residential, commercial, and industrial projects.

Cold Storage

Cold storage facilities demand rigid temperature control. Our cold storage panels provide top-notch thermal insulation that helps maintain consistent low temperatures. The panels resist condensation and humidity, preventing mold growth and keeping products fresh. This makes them a go-to for warehouses, food processing rooms, and refrigerated transport containers.

Prefabricated Structures

For prefab buildings, speed and efficiency are critical. Shanghe’s EPS foam sandwich panels are used in modular homes, offices, and temporary shelters due to their lightweight nature and ease of assembly. They support fast construction without compromising on strength or insulation, which is essential for modern prefab solutions.

Industrial Enclosures

Factories and industrial sites need durable, insulated enclosures for machinery and storage. These panels provide fire-resistant sandwich panels options that meet safety regulations while offering sound insulation to reduce operational noise. They also shield sensitive equipment from environmental factors without adding heavy structural loads.

Transportation

Transportation services incorporating thermal regulation, such as refrigerated trucks and shipping containers, benefit from these panels. The polystyrene foam panels help maintain stable temperatures, protect cargo, and reduce vehicle weight, improving fuel efficiency and lowering operating costs.

In all these applications, Shanghe EPS foam sandwich panels stand out because they combine cost-effective performance with eco-friendly materials and consistent quality from a trusted EPS foam sandwich panel manufacturer. Whether you are building, storing, or transporting, these panels are engineered to meet the unique demands of the U.S. market.

Technical Specifications of Shanghe EPS Foam Sandwich Panels

When choosing EPS foam sandwich panels for your project, knowing the technical details is crucial for making the right decision. Here’s a clear breakdown of the key specifications for Shanghe EPS panels, designed to meet diverse needs in the U.S. market.

Thickness Options

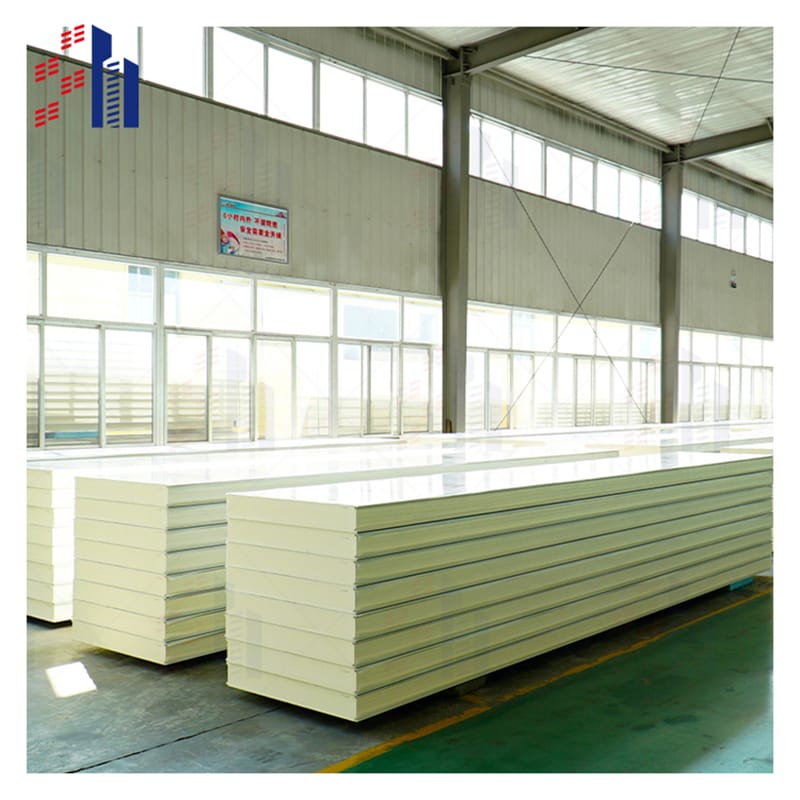

Shanghe offers EPS sandwich panels in a variety of thicknesses, typically ranging from 20mm up to 150mm. This flexibility lets you pick the perfect insulation level for your building, whether it’s cold storage or prefabricated construction.

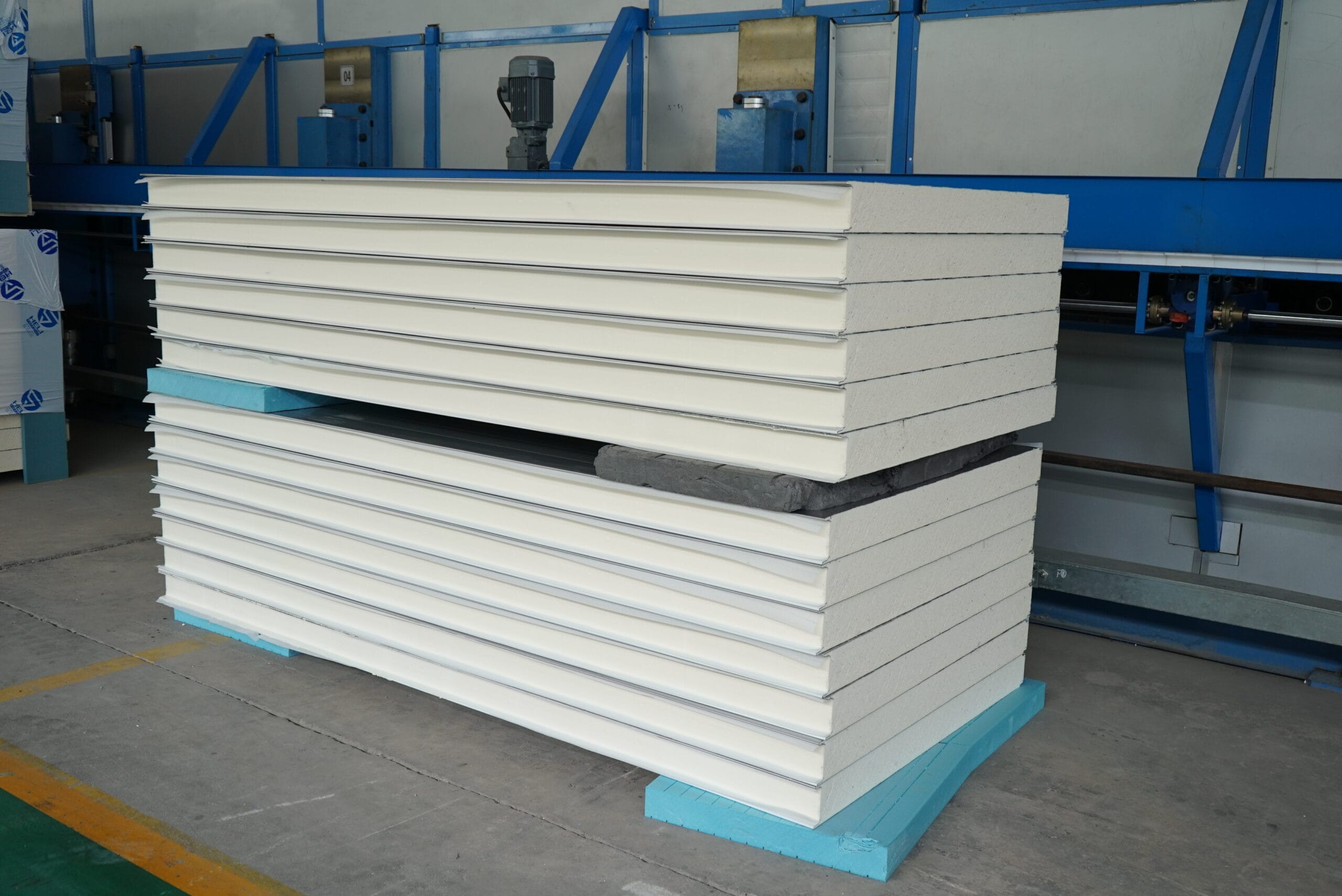

Width Options

The panels are commonly available in widths of 1000mm and 1200mm, which are standard sizes ideal for wall and roofing applications. This sizing optimizes installation efficiency and minimizes waste.

Core Density

The EPS foam core density ranges from 10 kg/m³ to 18 kg/m³. This density range balances thermal insulation performance with lightweight strength, making the panels effective for thermal retention without added bulk.

Surface Materials

Shanghe panels come with several surface options to match your structural and aesthetic needs:

- Galvanized steel for corrosion resistance and durability

- Aluminum sheets for lightweight and weather resistance

- PVC coated steel for enhanced moisture protection and longevity

These surface materials contribute to the panels’ fire resistance, durability, and ease of maintenance.

Length Customization

Panel lengths are customizable from 2 meters to 12 meters, allowing for tailored fits in any construction project. This customization reduces the number of joints and speeds up installation on site.

Fire Rating

Safety is a priority with Shanghe EPS foam sandwich panels, which hold a Class B1 fire rating under Chinese standards, equating closely to U.S. fire safety requirements for commercial applications. The panels are engineered to be fire-retardant, limiting flame spread and smoke emissions in case of fire.

In , Shanghe’s EPS foam sandwich panels offer a wide range of sizes and materials, delivering lightweight, durable, fire-resistant, and highly insulating solutions tailored for the U.S. market needs. Whether you need thermal insulation panels for cold storage or insulated wall panels for prefab buildings, these technical specs ensure you get a product that fits perfectly.

Why Choose Shanghe EPS Foam Sandwich Panels

When it comes to selecting EPS foam sandwich panels for your projects, Shanghe stands out for several strong reasons that benefit both contractors and end-users in the United States market.

Quality Control and Certifications

At Shanghe, we strictly follow quality control processes at every production step to ensure each panel meets high performance and standards. Our EPS sandwich panels undergo rigorous testing for:

- Thermal insulation efficiency

- Fire resistance

- Mechanical strength

- Moisture and soundproofing capabilities

We hold important international and local certifications that guarantee our products’ compliance with US building codes and safety requirements, including ASTM standards and UL fire ratings. This quality assurance reduces risk during construction and helps meet your project’s regulatory demands.

Comparison with Competitors

Compared to other polystyrene foam panels and suppliers in the US and abroad, Shanghe panels offer:

- Consistent core density and superior bonding between EPS foam and steel facings, resulting in more durable insulated wall panels.

- A wider range of customization options including thickness, surface materials (like galvanized steel or aluminum), and sizes to fit different applications.

- Competitive pricing without compromising quality, thanks to optimized manufacturing and bulk supply capabilities.

- Enhanced fire protection options over typical lightweight construction materials, making Shanghe panels a safer choice.

Customer Support and Delivery

Shopping for the right EPS foam sandwich panel can get complex, but with Shanghe you get more than just panels:

- Expert guidance: Our US-based support team helps you the right panel specs based on your climate, building type, and budget.

- Timely delivery: We partner with reliable logistics providers to offer fast and consistent shipping across the United States, including remote locations.

- After-sales service: From initial inquiry through installation, our team is available to resolve issues and answer questions promptly.

- Flexible ordering: Whether you need wholesale EPS foam sandwich panels or smaller orders, we accommodate your requirements with clear communication and transparent pricing.

Choosing Shanghe means you’re backed by a supplier that understands the US market’s need for fire-resistant sandwich panels, lightweight construction materials, and cost-effective insulated wall panels designed for long-term performance.

Installation and Maintenance Tips for EPS Foam Sandwich Panels

Installation Process for EPS Foam Sandwich Panels

Proper installation is key to getting the most out of your EPS foam sandwich panels. Here’s how to ensure a smooth, efficient setup:

- Prepare the surface: Make sure the supporting frame or wall is clean, level, and free of any debris. This helps the panels align perfectly.

- Panel handling: Lift and carry panels carefully. They are lightweight but can be damaged if dragged or dropped.

- Join panels securely: Use the appropriate fastening system like clips, screws, or adhesive recommended by the manufacturer to join panels tightly and prevent gaps. Overlapping joints and sealing with foam or tape improves insulation and weather resistance.

- Maintain alignment: Check alignment vertically and horizontally during installation to ensure panels sit flush and provide a smooth finished surface.

- Seal joints and edges: Weatherproof seals prevent moisture intrusion. Apply sealants or protective trims where panels meet other structural elements.

Following these steps will maximize the thermal and fire-resistant benefits of polystyrene foam panels in insulated wall panels or prefabricated structures.

Maintenance Advice for EPS Foam Sandwich Panels

Keeping your EPS sandwich panels in top shape is straightforward:

- Regular inspections: Check panels for any signs of damage such as cracks, dents, or water ingress. Early detection can prevent bigger issues.

- Cleaning: Use mild soap and water to clean surfaces. Avoid harsh chemicals that may degrade the panel’s surface materials.

- Repair minor damage: Small holes or cracks can be patched with compatible foam fillers or sealants to restore insulation and appearance.

- Protect from prolonged UV exposure: If your panels are exposed outdoors, consider applying a UV-resistant coating or install protective cladding.

Proper maintenance ensures your panels remain lightweight, durable, and perform well in thermal and sound insulation over time.

Safety Tips During Installation and Maintenance

Safety comes first with any building material handling:

- Wear protective gear: Gloves, safety glasses, and dust masks help protect against irritation from foam particles or sharp edges on galvanized steel sandwich panels.

- Handle panels carefully: Avoid dropping or bending panels to prevent damage and injury.

- Work in well-ventilated areas: If adhesives or sealants are used, ensure good airflow to minimize inhaling fumes.

- Keep fire safety in mind: Although fire-resistant sandwich panels have enhanced safety features, avoid open flames or sparks near panels during installation or repair.

By sticking to these guidelines, you’ll enjoy a hassle-free installation and long-lasting performance from your Shanghe EPS foam sandwich panels.

Comparing EPS Foam Sandwich Panels to Other Materials

When choosing insulated wall panels for your project, it’s important to understand how EPS foam sandwich panels stack up against other popular materials like PU panels, rockwool panels, and traditional options. Here’s a detailed look to help you make the right call.

EPS Foam Sandwich Panels vs PU Panels

- Thermal Insulation: Both EPS and PU panels offer good insulation, but PU (polyurethane) panels generally provide a slightly better R-value per inch. However, EPS panels remain highly effective, especially considering their cost advantage.

- Cost-Effectiveness: EPS panels are typically more affordable than PU panels, making them a smart choice for projects with tight budgets.

- Environmental Impact: EPS is more eco-friendly and easier to recycle compared to PU, which involves more complex chemicals.

- Fire Resistance: EPS panels from Shanghe come with reliable fire resistance, though PU panels often have improved fire-retardant properties by default.

- Moisture Resistance: PU panels tend to resist moisture better, but Shanghe EPS panels still offer good protection with proper surface coatings.

EPS Foam Sandwich Panels vs Rockwool Panels

- Sound Insulation: Rockwool sandwich panels excel at soundproofing due to their dense, fibrous core. EPS panels provide decent sound insulation but are not the top choice for noise-sensitive projects.

- Fire Resistance: Rockwool panels are naturally fire-resistant and can withstand higher temperatures, offering excellent flame retardancy.

- Weight: EPS panels are much lighter, simplifying handling and installation compared to the heavier rockwool panels.

- Cost: EPS panels are generally more affordable, while rockwool panels can be pricier due to raw material and manufacturing complexity.

- Moisture Behavior: EPS resists moisture better, preventing mold and mildew, whereas rockwool’s open structure can absorb water if not properly sealed.

EPS Foam Sandwich Panels vs Traditional Materials

- Thermal Efficiency: Traditional building materials like brick or concrete lack the built-in insulation that EPS sandwich panels offer, often requiring extra insulation layers.

- Installation Speed: EPS foam sandwich panels deliver quick, easy installation due to their lightweight and prefab nature, reducing labor costs and project timelines.

- Durability: While traditional materials are sturdy, EPS panels combine strength with flexibility, resisting impact and weather damage effectively.

- Cost and Maintenance: EPS panels usually offer lower overall costs when factoring in installation time, insulation value, and maintenance, compared to traditional walls that may require frequent upkeep.

- Sustainability: EPS panels can be reused and generate less construction waste, aligning better with green building practices common in the U.S. market.

Shanghe EPS foam sandwich panels provide a balanced choice — combining strong thermal insulation, lightweight construction, cost-effectiveness, and eco-friendly benefits. While PU and rockwool panels offer specific advantages in fire resistance and soundproofing, EPS panels are a versatile, reliable solution for many commercial, residential, and industrial applications. Compared to traditional materials, EPS panels streamline construction projects and enhance energy efficiency, making them well-suited for modern building demands.

How to Order Shanghe EPS Foam Sandwich Panels

Ordering Shanghe EPS foam sandwich panels is straightforward and designed to fit your project needs, whether you’re in construction, cold storage, or prefabricated building sectors. Here’s how to get started:

Contact and Request a Quote

Reach out to our sales team for a personalized consultation and a precise quote. Provide details such as:

- Panel thickness, size, and core density requirements

- Surface material preference (galvanized steel, aluminum, etc.)

- Project scope and application

This helps us tailor the best solution, ensuring you get cost-effective insulated wall panels that meet your specifications. You can contact us directly through our website or email, where we respond promptly to inquiries.

Global Shipping and Consultation

Shanghe EPS foam sandwich panels are available for shipment worldwide. We support logistics to the United States and other regions, ensuring your order arrives on time and in perfect condition. Our team offers:

- Guidance on shipping options and delivery schedules

- Consultation on panel selection based on climate, fire safety, and soundproofing needs

- Assistance with customs paperwork and compliance

By handling these details, we simplify the purchasing process, so you get peace of mind from order to delivery.

Call to Action

Ready to improve your build with lightweight fire-resistant EPS sandwich panels from a trusted supplier? Contact Shanghe today for your quote and expert advice.

Visit our product pages like insulated sandwich panels or cold room sandwich panel to view options and specifications, then get in touch to place your order.

Choose Shanghe for reliable quality, competitive pricing, and worldwide support on all your EPS foam sandwich panel needs.

Frequently Asked Questions About EPS Foam Sandwich Panels

Fire Safety Ratings of EPS Foam Sandwich Panels

Shanghe EPS foam sandwich panels meet stringent fire safety standards required across the U.S. market. Our panels are tested for compliance with ASTM E84, showing excellent flame spread and smoke development ratings. While EPS itself is combustible, our sandwich panel design incorporates fire-resistant facings and fire retardant additives in the core to improve safety. This ensures reliable protection for commercial and residential insulated wall panels applications.

Usage in Extreme Climates

Our EPS foam sandwich panels perform consistently in extreme weather, from frigid cold storage to hot, humid conditions. The high thermal insulation capability keeps interiors stable, reducing energy costs year-round. The panels also resist moisture absorption, preventing issues like mold or warping, making them suitable for prefabricated building panels used in areas with large temperature swings.

Price Comparison with Other Insulated Panels

EPS foam sandwich panels offer a cost-effective solution compared to PU (polyurethane) andwool panels. Although PU panels may have slightly better insulation values, EPS panels balance price and performance, providing excellent value without compromising durability. When looking at lightweight construction materials, EPS panels typically cost less upfront and require less structural support, lowering overall project expenses.

Lifespan and Durability

Shanghe EPS panels are designed to last 20 to 30 years with proper installation and maintenance. Their durable facings—usually galvanized steel or aluminum—protect the polystyrene core from physical damage and environmental wear. This longevity makes EPS foam sandwich panels a smart investment for long-term projects like industrial enclosures and transportation containers.

Customization Options for EPS Foam Sandwich Panels

We understand different projects have unique needs. That’s why Shanghe offers wide customization options including:

- Thickness ranging from 1 to 6 inches for varied insulation needs

- Flexible panel widths and lengths to fit any space

- Various surface materials like galvanized steel, aluminum, or PVC coatings

- Custom core densities tailored for specific strength and insulation requirements

- Optional fire retardant treatments and color matching

This flexibility ensures our panels meet your exact project specs whether for commercial or residential use.

For reliable thermal insulation panels that combine affordability, durability, and flexibility, Shanghe EPS foam sandwich panels stand out as a top choice in the U.S. market. Feel free to reach out for any other questions or detailed specifications.