What Makes EPS Sandwich Panels a Top Choice for Modern Building Materials?

EPS sandwich panels are changing the game in construction—they’re lightweight, tough, and budget-friendly. These panels layer steel on the outside with an EPS (expanded polystyrene) foam core in the middle, giving you killer thermal insulation and rock-solid strength. They’re perfect for building warehouses, factories, or stores because they slash construction time by half compared to old-school methods. LEED-certified projects love ’em for cutting heating and cooling bills by 30-40%. Plus, you can tweak their design for walls, roofs, or even dividers. If you want something that works hard without breaking the bank, EPS sandwich panels are your go-to.

Panel EPS Solutions for Noise Reduction in Urban Construction

Tired of city noise? EPS sandwich panels are like earmuffs for your building. That dense foam core soaks up 30 decibels of racket—perfect for apartments near airports or busy roads. Take Chicago high-rises: after slapping on EPS wall panels, ambient noise dropped 40%. Unlike concrete, you can retrofit these panels easily. Building a studio or a quiet office? EPS turns noise chaos into zen mode.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

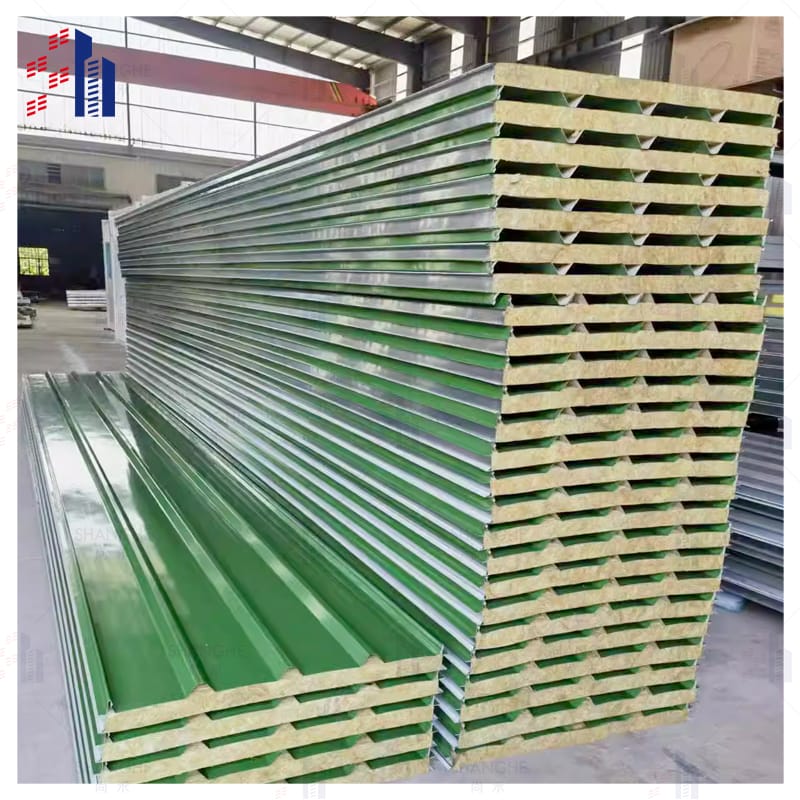

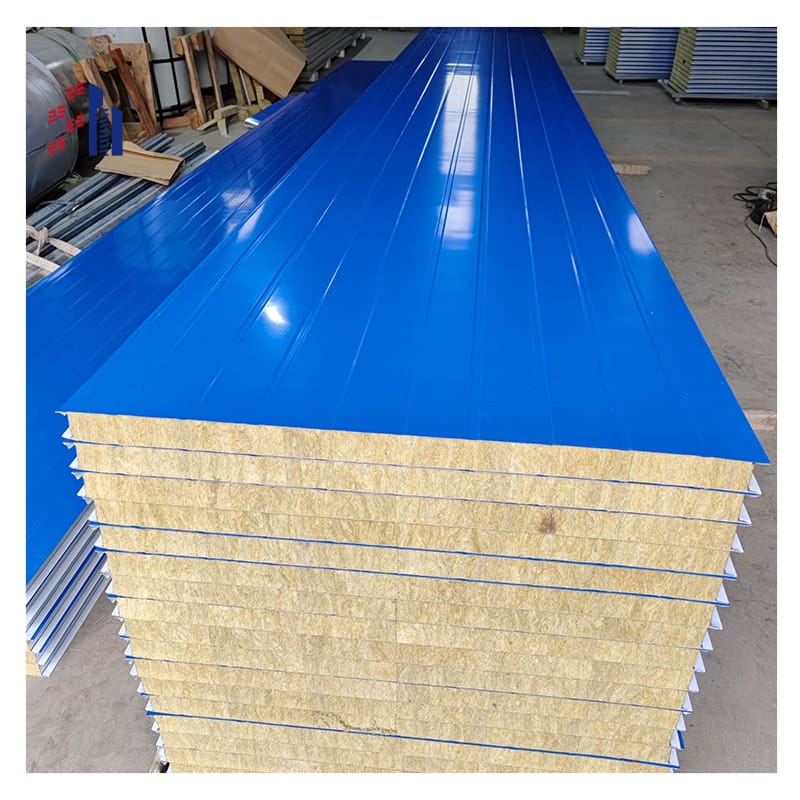

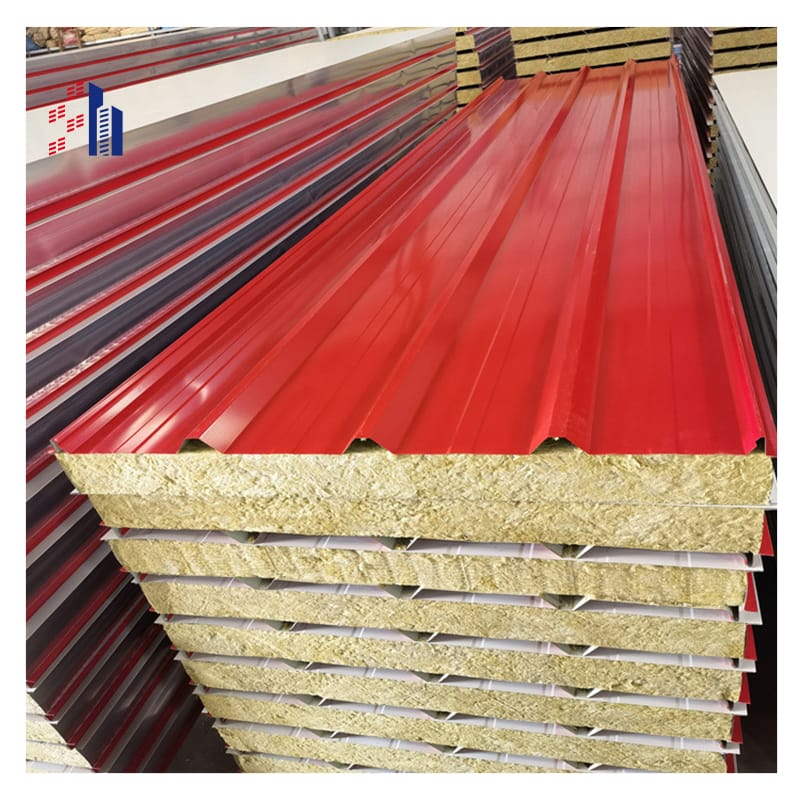

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Expanded Polystyrene (EPS): The Secret Behind High-Performance Sandwich Panels

Forget coffee cups—EPS is the MVP inside sandwich panels. Its closed-cell foam fights off moisture, mold, and bugs, which is why USDA-approved cold storage spots swear by it. Unlike other insulations that sag, EPS keeps its R-value (insulation power) for decades. Bonus: it’s 100% recyclable, fitting right into eco-friendly goals. From house walls to factory roofs, this foam makes panels tough and versatile.

Sandwich Panels with EPS Core: Faster Builds, Stronger Results

EPS-core sandwich panels are a contractor’s dream—they save time and cash. Prefab design means crews can slap up walls or roofs three times faster than brick-and-mortar. Walmart’s Texas warehouse finished eight weeks early using these panels. The steel-EPS combo also laughs at hurricanes, passing Miami-Dade’s brutal wind tests. Fewer delays, happier clients—what’s not to love?

Sound Insulation? EPS Sandwich Panels Quiet the Competition

EPS sandwich panels aren’t just for heat—they’re noise-canceling pros. The foam busts up sound waves, making them gold for hotels, theaters, or homes near highways. UCLA researchers found EPS panels cut mid-frequency noise by half compared to drywall. They’re also thinner than old-school soundproofing, saving space. Want quiet without chunky walls? EPS’s got you covered.

Multi-Span Buildings Love EPS Sandwich Panels—Here’s Why

Big, open buildings need materials that handle long spans and heavy loads. Enter EPS sandwich panels—steel skins and rigid foam make ’em tough yet light. Farmers use ’em for mega-barns that survive tractors and blizzards. Fewer support columns mean wide-open spaces, like Tesla’s Nevada factory floor where robots zoom freely. Efficiency meets flexibility, no sweat.

Low Thermal Conductivity in EPS Panels: Cold Climates’ Best Friend

EPS panels are insulation champs because they barely let heat slip through. With thermal conductivity as low as 0.030 W/m·K, they beat wood, concrete, and fancy aerogels. How? Those air-packed EPS beads slow heat loss. Arctic warehouses or desert offices—these panels handle extremes like bosses.