What Are Fiber Cement Sandwich Panels

Fiber cement sandwich panels are prefabricated building panels made by bonding strong fiber cement or calcium silicate skins to a lightweight foam core. This combination creates a panel that is both sturdy and efficient. The outer layers provide protection and durability, while the core offers excellent thermal insulation and reduces overall weight.

Key features include:

- Fire resistance: Fiber cement skins are non-combustible, making these panels a safe choice for buildings in fire-prone areas.

- Thermal insulation: The foam core offers superior insulation, helping keep energy costs down and maintaining comfortable indoor temperatures.

- Soundproofing: The layered structure dampens noise, ideal for residential and commercial spaces.

- Durability: Resistant to weather, moisture, pests, and impacts, these panels last longer with low maintenance.

Compared to alternatives like wood-based or aluminum sandwich panels, fiber cement sandwich panels stand out for their fire safety and moisture resistance. Wood panels may falter under humidity and are less fireproof, while aluminum panels, although lightweight, often lack comparable insulation and soundproofing. Fiber cement panels balance strength, comfort, and safety effectively, fitting well in harsh climates and demanding environments.

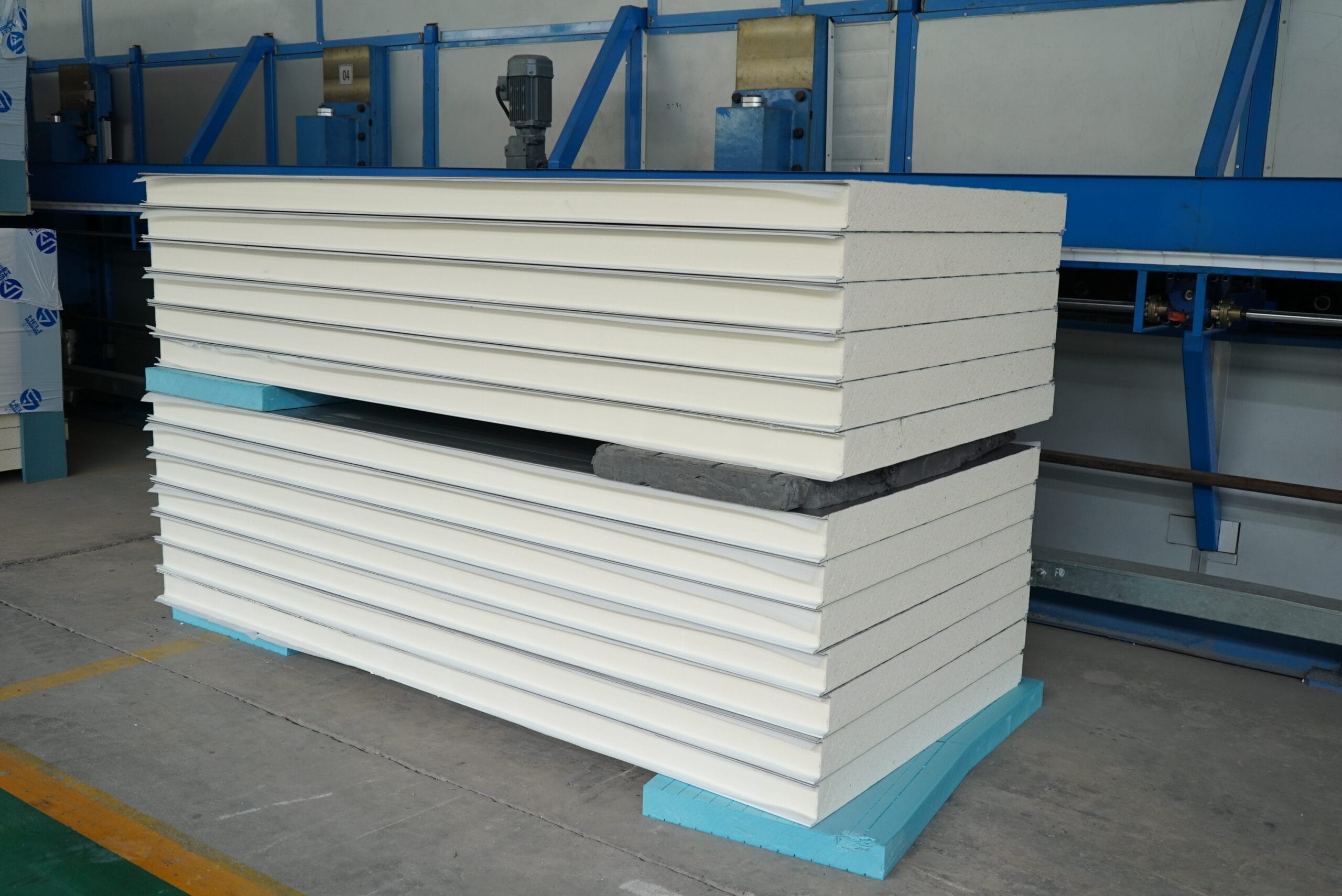

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Benefits of Fiber Cement Sandwich Panels

Fiber cement sandwich panels offer a range of benefits that make them ideal for many building projects, especially in the US where weather and energy efficiency are top concerns.

- Durability: These panels stand up well against harsh weather, pests, and fire. Whether you’re dealing with storms, humidity, or termites, fiber cement holds strong without warping or rotting.

- Sustainability: Made from eco-friendly materials, fiber cement sandwich panels have low VOC emissions and are recyclable. This supports greener building practices and helps meet environmental standards.

- Energy Efficiency: With excellent thermal insulation, these panels help keep homes and buildings cooler in the summer and warmer in the winter. This means lower energy bills—something homeowners and businesses both appreciate.

- Versatility: You can use fiber cement sandwich panels for exterior walls, interior walls, partitions, and cladding. Their design fits a variety of architectural styles and project needs, from residential to commercial.

- Cost Effectiveness: Thanks to a long lifespan and minimal maintenance requirements, these panels offer great value over time. You save on repairs, replacements, and upkeep compared to other materials like wood or metal.

If you’re also considering other options, check out our wood sandwich panels or metal sandwich panels for side-by-side comparisons.

Applications of Shanghe’s Fiber Cement Sandwich Panels

Shanghe’s fiber cement sandwich panels are a solid fit for many building types across the U.S. market.

Residential Uses

These panels work great in homes — from upscale villas and modular homes to large apartment complexes. They offer strong thermal insulation and weather resistance, making them ideal for varying climates across states. Plus, they give exterior wall cladding a sleek, modern look while keeping maintenance low.

Commercial Applications

Offices, hotels, and retail spaces benefit from the panels’ fire resistance and soundproofing. These features create safer, quieter environments without sacrificing style or efficiency. The lightweight design helps speed up installation on commercial projects, saving time and labor costs.

Industrial Use

Factories, warehouses, and agricultural buildings rely on durable materials that hold up to harsh conditions. Shanghe’s panels resist pests, moisture, and impact, which helps protect these large spaces from damage and costly repairs.

Public Infrastructure

Schools, hospitals, and community centers demand reliable, sustainable construction solutions. Our fiber cement sandwich panels meet strict safety codes and deliver great energy efficiency, supporting long-term operational savings for public facilities.

Case Study

A recent sustainable office building project using Shanghe’s panels showcased their strengths perfectly. The client saw lower energy bills thanks to excellent thermal insulation, plus enhanced fire safety and quick installation times. The result was a well-performing, eco-friendly workspace built on budget and on schedule.

These broad applications highlight why fiber cement sandwich panels from Shanghe are a top choice for many construction needs around the country.

Why Shanghe Stands Out as a Supplier

Shanghe leads the pack by focusing on top-notch manufacturing. They use advanced technology and have strict quality control to make sure every fiber cement sandwich panel meets high standards. This means you get panels that perform consistently, whether you’re building in a harsh climate or a busy city.

Customization is another strong point. Shanghe offers tailored sizes, thicknesses, and finishes to fit your specific project needs. Whether you need thicker panels for extra insulation or a particular finish for aesthetic appeal, they’ve got options that work.

Eco-conscious production is part of their mission. Shanghe uses sustainable materials and follows green manufacturing processes, keeping environmental impact low. This aligns well with growing demand in the U.S. for eco-friendly building materials and sustainable construction solutions.

Their global distribution network covers key markets like the U.S., Europe, and Asia, making it easier to source quality fiber cement sandwich panels no matter where your project is. Plus, Shanghe’s customer support stands out by guiding you every step of the way—from initial design choices to final installation—helping you avoid common pitfalls and get the most from your panels.

Installation and Maintenance Tips

Installation Guide

Installing fiber cement sandwich panels right ensures they perform well and last long. Here’s a simple step-by-step:

- Tools Needed: Use a circular saw with a diamond blade or fiber cement blade for clean cuts. You’ll also need a drill, screwdrivers, measuring tape, level, and safety gear like gloves and goggles.

- Cutting Techniques: Always cut panels outside or in a well-ventilated area to avoid dust buildup. Score lightly first, then snap for cleaner edges. Avoid chipping by cutting slowly and steadily.

- Panel Fixing: Secure panels to the supporting frame with corrosion-resistant screws. Leave slight gaps (about 3-5mm) between panels to allow for expansion.

- Sealing Joints: Use high-quality, weatherproof sealant on joints to prevent water infiltration and improve insulation.

- Safety Precautions: Work with proper safety gear. Fiber cement dust can be harmful if inhaled, so wear a mask and keep the area ventilated.

Maintenance Tips

Keeping your panels in good shape takes just a bit of care:

- Cleaning: Wash panels periodically with mild soap and water to remove dirt and prevent buildup.

- Check Joints: Inspect seals and joints every few months. Reapply sealant where cracks or gaps appear.

- Minor Repairs: Fill small chips or holes with fiber cement patching compounds promptly to stop damage from spreading.

- Avoid Harsh Chemicals: Use gentle cleaning products to maintain the panels’ integrity.

Professional vs DIY Installation

For best results, hiring a certified installer is usually the way to go because:

- Experience: Professionals know the correct techniques to avoid common mistakes.

- Warranty: Many manufacturers require certified installation for warranty coverage.

- Time and Efficiency: Pros get the job done faster and often with less waste.

If budgeting for DIY, make sure you have the right tools, skills, and safety measures in place. Don’t forget to check local building codes before starting.

For detailed specs and product options, check out our thermal insulation sandwich panel and fireproof sandwich panel product pages.

Comparing Fiber Cement Sandwich Panels to Alternatives

When choosing building materials, it helps to see how fiber cement sandwich panels stack up against other popular options.

Fiber Cement vs EPS Cement Panels

- Core material difference: Fiber cement panels use foam cores but typically have stronger, denser fiber cement or calcium silicate skins. EPS panels have expanded polystyrene cores, which are lighter but less fire-resistant.

- Performance: Fiber cement panels offer better fire resistance and durability, while EPS panels are more lightweight but can be less sturdy under impact.

Fiber Cement vs Wood-Based Panels

- Moisture resistance: Fiber cement panels handle moisture much better, making them ideal for humid or wet climates common in many U.S. regions.

- Pest resistance: Unlike wood panels, fiber cement is naturally resistant to termites and other pests, reducing maintenance and replacement costs.

Fiber Cement vs Metal Panels

- Weight and insulation: Fiber cement panels are lighter than metal panels and provide better thermal insulation, helping improve energy efficiency.

- Corrosion: Metal panels may corrode over time, especially in coastal areas, while fiber cement resists rust and degradation.

Materials Cost and Performance

| Panel Type | Weight | Fire Resistance | Moisture Resistance | Pest Resistance | Thermal Insulation | Average Cost |

|---|

| Fiber Cement Sandwich | Medium | High | High | High | High | Moderate |

| EPS Cement | Low | Moderate | Moderate | Moderate | Moderate | Low |

| Wood-Based | Medium | Low | Low | Low | Moderate | Moderate |

| Metal | High | Moderate | High | High | Low | High |

Fiber cement sandwich panels offer a solid balance of durability, insulation, and cost, making them a smart choice for American builders facing diverse weather and building demands.

How to Choose the Right Fiber Cement Sandwich Panel

Picking the right fiber cement sandwich panel means thinking about a few key factors. First, consider the thickness—panels usually come in 50mm, 70mm, or 100mm. Thicker panels offer better insulation and strength but might cost more and weigh a bit more. Next, look at the core type, like foam or other insulating materials, since this affects thermal performance and soundproofing. The skin material matters too, especially if you need extra durability or specific finish options for your project.

At Shanghe, we offer a solid range of panels that fit different needs, whether you’re working on a residential, commercial, or industrial build. Our panels come in various thicknesses to match your insulation requirements and budget.

When sourcing fiber cement sandwich panels, keep these tips in mind:

- Verify certifications to ensure quality and safety standards.

- Request samples so you can check the finish and feel before buying.

- Read customer reviews to learn about real-world performance and supplier support.

This approach helps you choose the right panel that fits your project and lasts for years in tough U.S. weather conditions.