Why Are Fibreglass Sandwich Panels Revolutionizing Composite Panel Technology?

Fibreglass sandwich panels are taking the composite panel industry by storm—and here’s why. These panels combine a lightweight fibreglass outer layer with a high-strength core material (like foam or honeycomb), creating a rigid yet surprisingly light structure. Think of them as the Swiss Army knife of building materials: they’re used in everything from boat hulls to aircraft interiors because they resist corrosion, won’t rust, and handle extreme temps like a champ. Boeing even uses fibreglass panels in cargo planes for their durability-to-weight ratio. If you’re tired of heavy steel or flimsy plastics, these panels are a game-changer. Plus, they’re LEED-friendly, making them a go-to for eco-conscious projects.

How Carbon Fiber Complements Fibreglass Sandwich Panels for Maximum Strength

Alright, let’s talk teamwork. Fibreglass sandwich panels are solid on their own, but add carbon fiber? Now you’re playing in the big leagues. Carbon fiber strips or layers beef up the strength without turning your project into a heavyweight. NASA’s Jet Propulsion Lab does this for satellite parts—because if it works in space, it’ll work anywhere. For example, high-speed trains use this hybrid trick to stay light but survive crashes. It’s like giving your design a turbo boost. And hey, you’re not paying Lamborghini prices here—just smart engineering.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | fibreglass sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

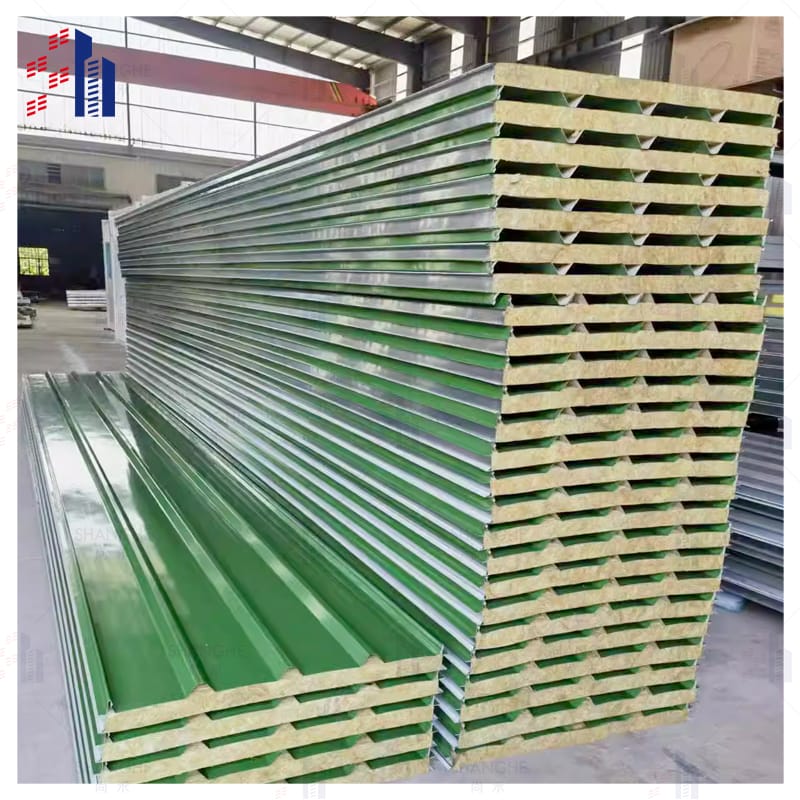

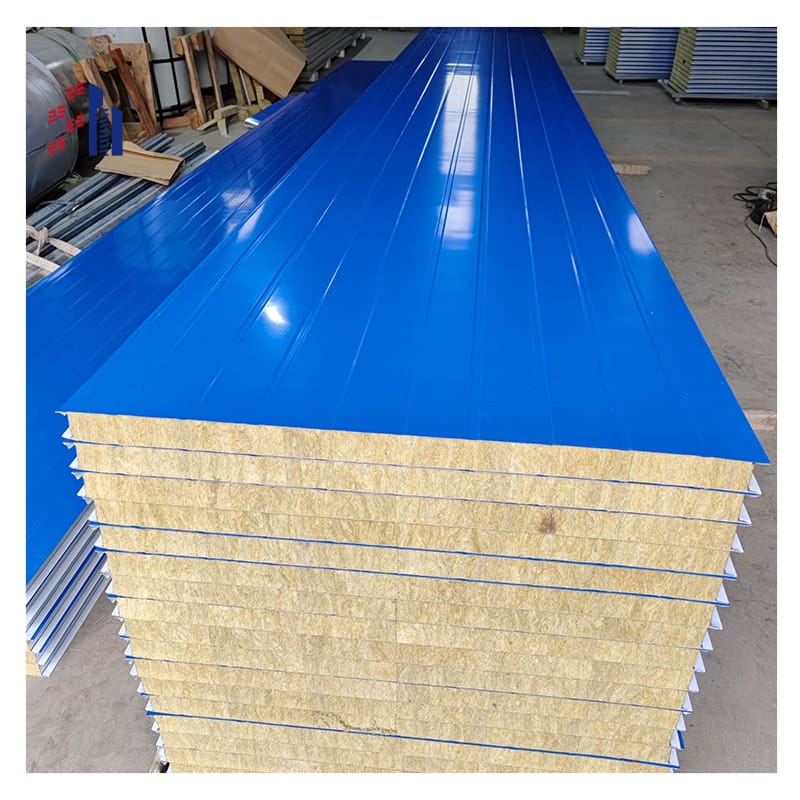

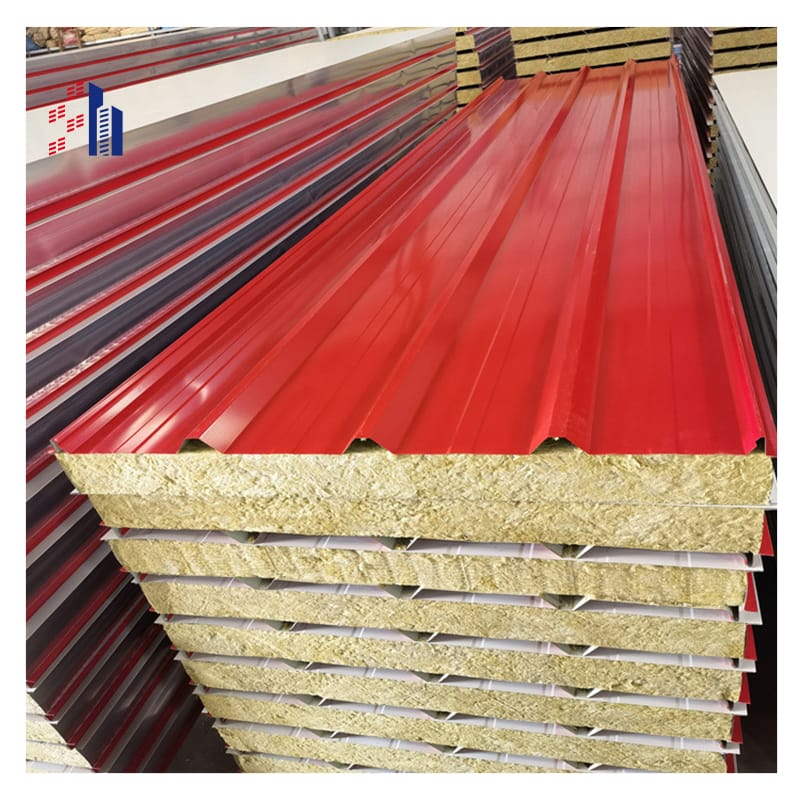

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why High-Strength Fibreglass Panels Outperform Traditional Building Materials

Let’s get real: wood rots, steel rusts, but high-strength fibreglass panels? They just don’t quit. Seriously, these things laugh off rain, UV rays, and even harsh chemicals. Boat makers swear by ’em because saltwater’s no match. MIT did a study showing fibreglass keeps 95% of its strength after 50 years—meanwhile, concrete’s cracking and metal’s getting tired. Oh, and they’re fire-resistant too (thanks, ASTM E84 ratings). Building a bridge or a hurricane-proof house? These panels are the “install once and forget” solution.

Core Materials in Fibreglass Sandwich Panels: What You Need to Know

So here’s the deal: the core material is where the magic happens. You’ve got options—like PVC foam for insulation or aluminum honeycomb for when you need “indestructible” mode (fighter jets use this stuff). Airbus goes with polyurethane foam in planes to kill noise and vibrations. But wait—the core you pick changes everything. Want your panel to float? Go with a lightweight foam. Need it to survive a wrecking ball? Honeycomb’s your jam. Architects dig balsa wood cores for eco-projects because they’re renewable. Bottom line: match the core to your project’s vibe.

Fire-Resistant Fibreglass Sandwich Panels: Safety Without Sacrificing Strength

Fire safety doesn’t have to be boring. Fibreglass sandwich panels can be loaded with fire-retardant resins and cores like mineral wool, hitting UL 94 V-0 ratings (translation: they nope out of flames fast). Hospitals use ’em in fire-rated walls because every second counts in an emergency. A Vegas casino redid its walls with these panels to pass fire codes but keep that glitzy look. And hey, they still hold up heavy loads—no “safe but flimsy” nonsense here.

How Fibreglass Panels Slash Costs in Industrial Construction

Let’s talk cash. Fibreglass sandwich panels save money faster than a coupon frenzy. They’re light, so shipping’s cheap, and you can install ’em without cranes. Ford’s Michigan factory saved 15% on labor using prefab fibreglass roofs. Farmers build whole barns with basic tools—no contractors needed. And since they don’t rust or rot, maintenance costs? Basically zero. Warehouses, greenhouses, highway barriers—these panels keep your wallet happy.

Fibreglass vs. Carbon Fiber Sandwich Panels: Which Should You Choose?

Fibreglass or carbon fiber? Here’s the skinny. Fibreglass is cheaper (like, way cheaper) and bends easily—perfect for curved boat hulls. Carbon fiber’s stiffer and lighter, but your budget might cry. Lamborghini uses carbon fiber for flashy cars, but RV makers stick with fibreglass ’cause it’s affordable. Pro tip: Mix ’em! Add carbon fiber strips to high-stress spots on a fibreglass panel. Unless you’re Elon Musk, fibreglass’ll probably do the trick.