Stop Burning Cash on Outdated Building Systems! Meet the Foam Concrete Sandwich Panel Revolution

Hi there, I’m David. For 20 years in Shanghe’s panel industry, I’ve watched contractors lose profits to slow installs, architects sweat over leaky specs, and owners drown in energy bills. That’s why I’m fired up about foam concrete sandwich panels—your real fix for modern builds. No fluff, just facts. Let’s dive in.

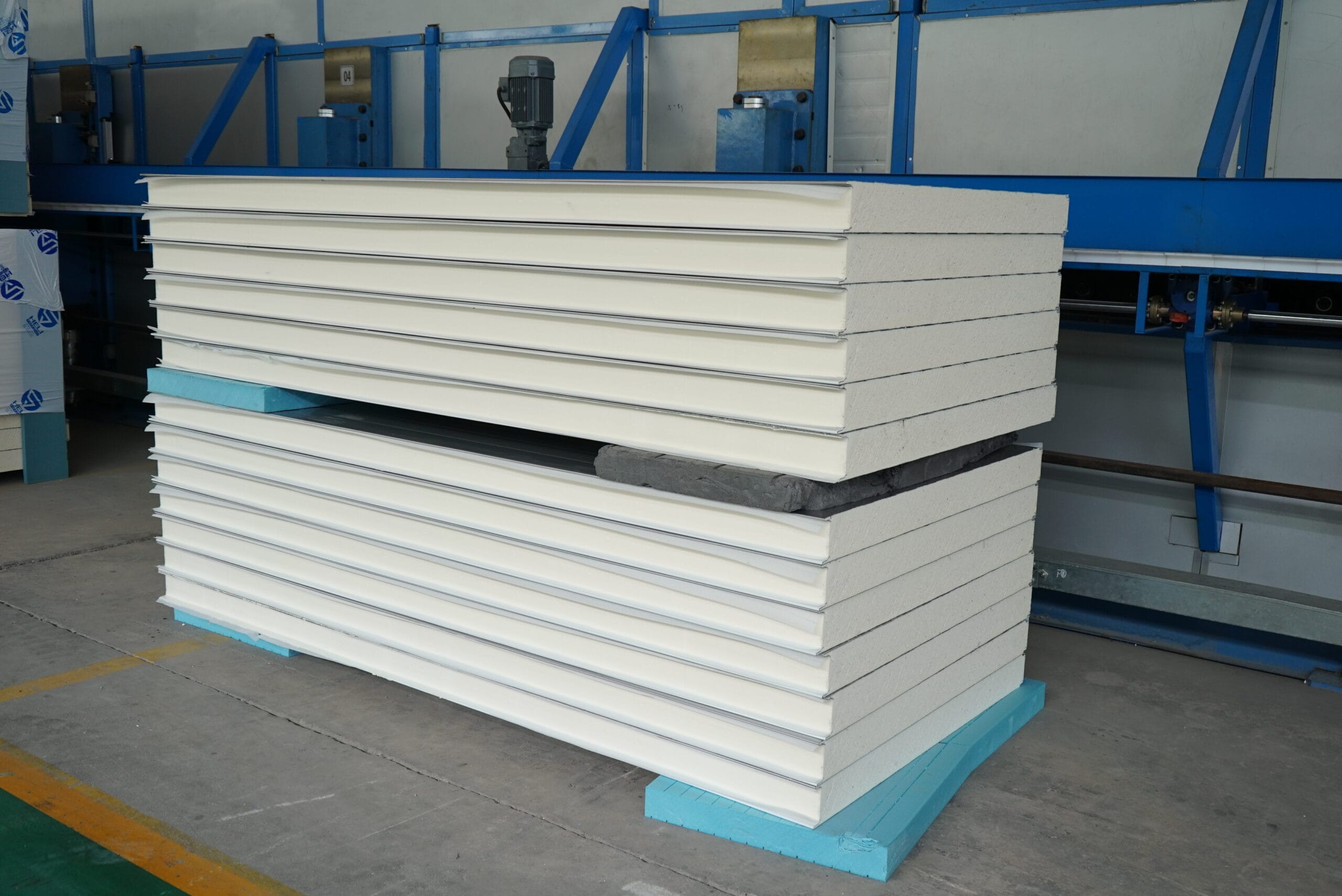

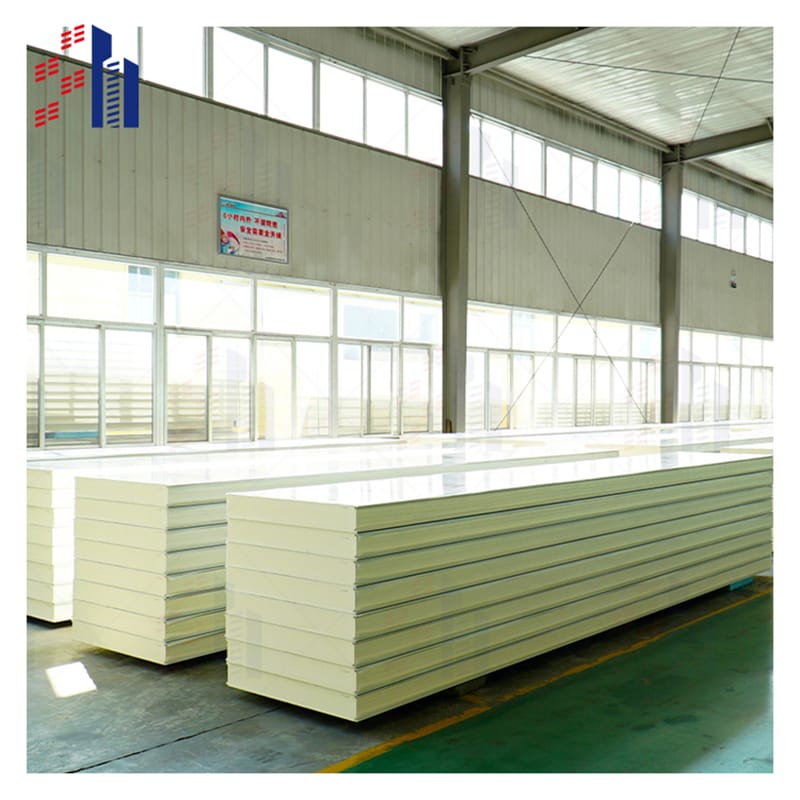

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Foamed Pcw |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Tired of Fire Risks? Foam Concrete Sandwich Panels Deliver Non-Negotiable Safety

Here’s the deal: traditional panels can torch budgets and buildings. Our foam concrete sandwich panels pack a mineral-based core that laughs at 1,000°C flames for 4+ hours—zero toxic fumes, full Class A compliance 16. Think of it like a firefighter built into your walls. For architects chasing LEED or FM Global specs, this isn’t just “nice-to-have.” It’s your insurance against failed inspections and lawsuits.

Need Speed? Precast Lightweight Foamed Concrete Sandwich Panels Slash Labor by 40%

Let’s be real: time is money. While your crew wrestles brick or steel, competitors using precast lightweight foamed concrete sandwich panels are locking walls in hours. Three workers install 75m²/day 3—like LEGO for pros. Contractors, picture this: shorter site rentals, fewer overtime headaches, and projects finished before penalties kick in.

Energy Bills Skyrocketing? Lightweight Foam Sandwich Panels Trap Savings Year-Round

Owners, listen up: that “cheap” traditional build? It’s bleeding $500/month on HVAC. Our lightweight foam sandwich panels lock in R-values 3× better than EPS cores 5. Winter stays in. Summer stays out. Period. Universities like Xi’an Jiaotong validated it: aluminum foam cores (cousin tech!) absorb energy 37% better 49. Translation? Slash bills by 30%—or redirect that cash to premium finishes tenants actually notice.

Hate Wasted Material? Precast Lightweight = Precision + Planet Wins

Chaotic sites. Piles of cut-offs. Dumpsters overflowing. Sound familiar? Precast lightweight panels arrive custom-sized (2270x610mm standard 6)—cut once, install perfect. Zero mortar waste. Zero “oops” reorders. Plus, LEED teams love our EPDs: 100% recyclable cores, asbestos-free builds, and 60% lower CO₂ than concrete 2. Even the Pentagon uses similar tech for bomb-resistant structures 10. If it’s tough enough for them, it’s overkill for your mall.

Fear Storms or Quakes? Sandwiched Concrete Foam Panels Outmuscle Mother Nature

Hurricane zones? Earthquake country? No sweat. Sandwiched concrete foam panels bond reinforced skins to a shock-absorbing core. Tests show 8-level quake resistance and 50kg single-point hangs 36. For coastal contractors in Florida or Japan, that’s code compliance and marketing gold. Owners sleep easy; architects spec smarter.

Why David’s Panels? 20 Years, 4 Million m²/Year, Zero Compromises

Look, I’ve seen “cheap” imports warp, delaminate, and fail LEED checks. As a top foam concrete sandwich panel supplier in China, we control quality from raw mix to shipping:

Certified Tough: CE, ISO, FM Global—no gray-area specs 36.

Custom Freedom: Need a quirky curve or RAL 5017 blue? Done.

Volume Heroes: 4M m²/year output = no delays + wholesale rates