The Lightweight, High-Strength Solution Backed by NASA and Boeing

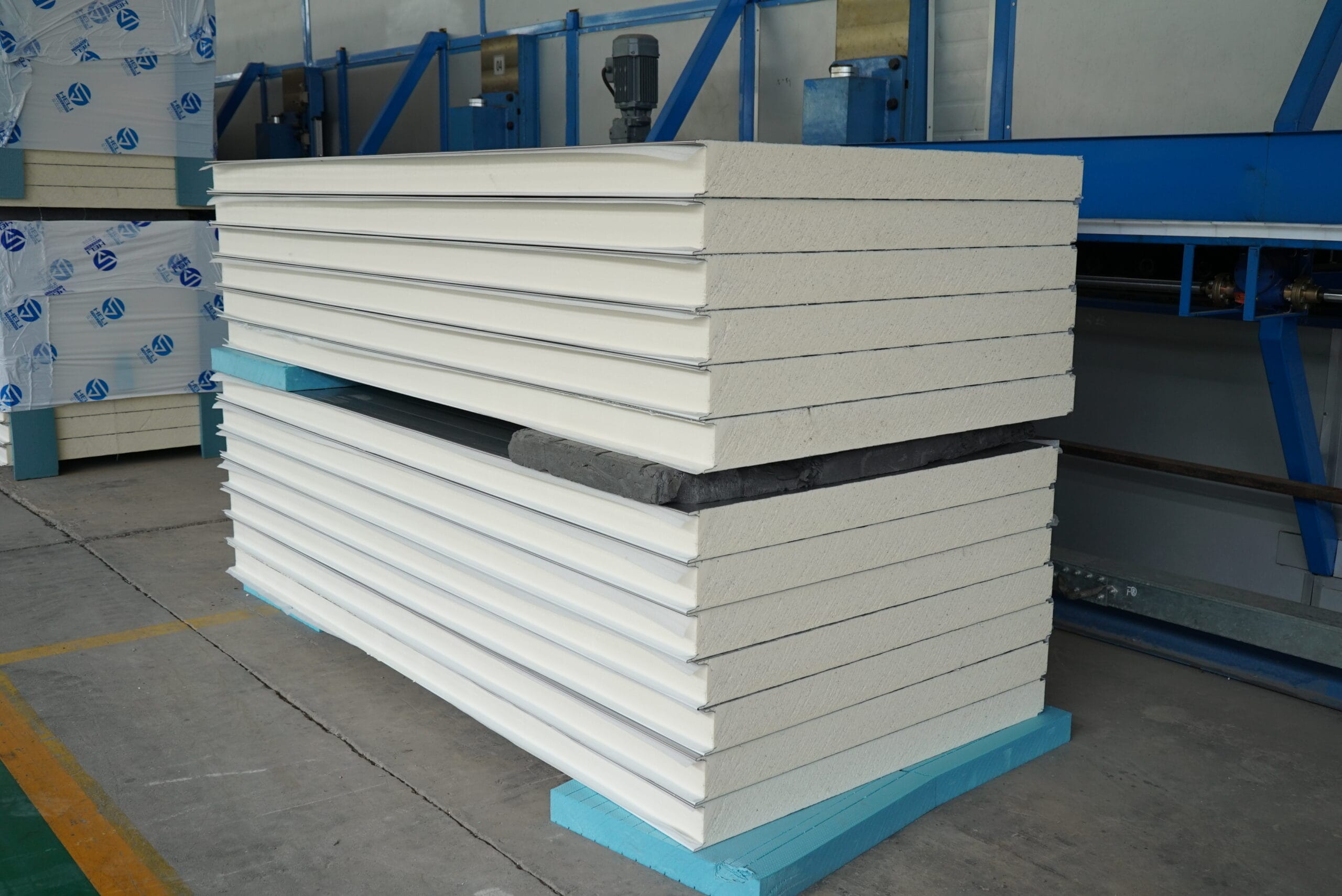

If you’re looking for a building material that’s both lightweight and incredibly strong, foam core sandwich panel are the answer. Used by industry giants like NASA and Boeing, these panels combine a lightweight foam core with durable outer skins to create a structure that’s tough yet easy to handle. The secret? The foam core distributes stress evenly, making it perfect for everything from aerospace to high-performance construction.

Customers visit the factory

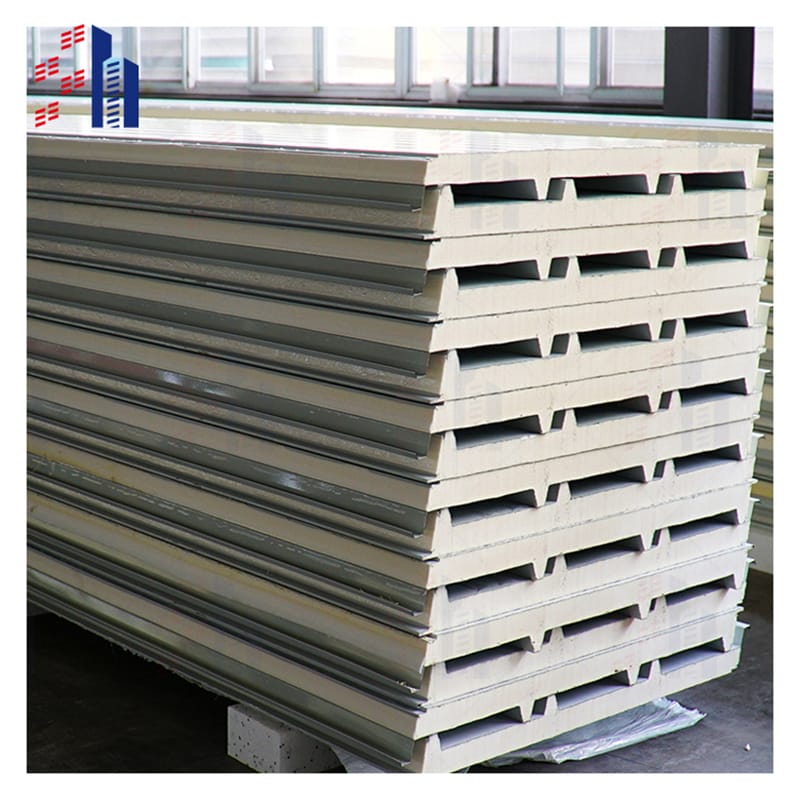

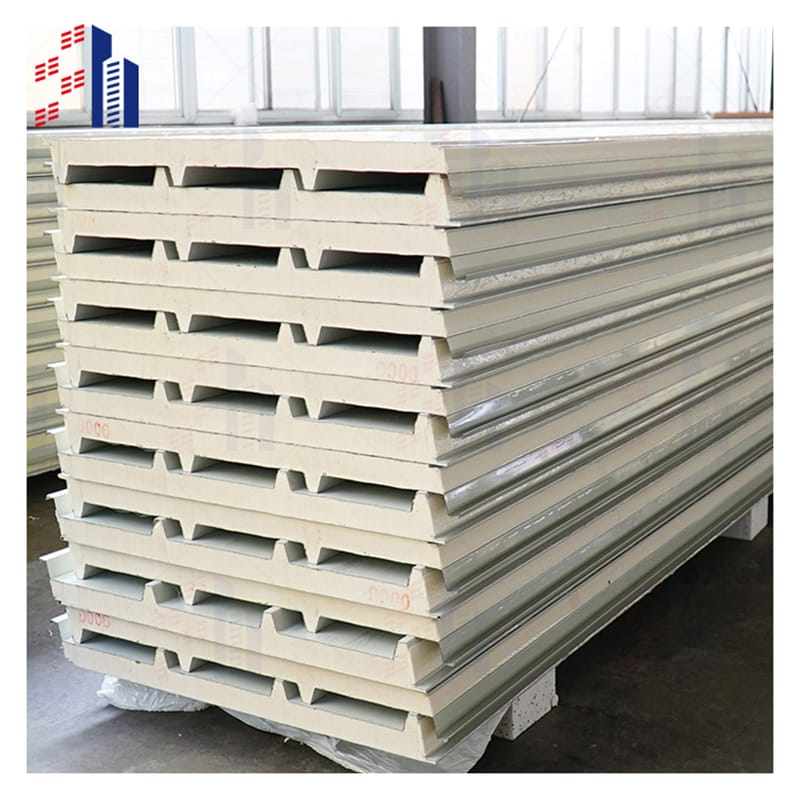

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyisocyanurate (PIR) Foam – *0.25lb/ft³ density* | Highest R-value per inch, no CFCs |

| Fire Rating | Class A1 (EN 13501) / ASTM E84 Flame Spread ≤25 | Safe for schools, hospitals, and warehouses |

| Thermal R-Value | R-6.5 per inch (λ=0.023 W/m·K) | Saves 30% on HVAC vs. fiberglass |

| Panel Thickness | 1″ to 6″ (customizable) | Thicker = better insulation for cold climates |

| Max Panel Size | 12’ x 4’ (larger sizes OEM-only) | Fewer seams = faster install |

| Face Materials | 0.02″–0.04″ Aluminum, Galvanized Steel, or FRP (smooth/embossed) | Steel for durability, aluminum for coastal |

| Load Capacity | 40 psi compressive strength (holds roof snow loads) | OSHA-compliant for industrial use |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Take Boeing’s 787 Dreamliner, for example—it uses foam core sandwich panel to reduce weight without sacrificing strength. Even the U.S. military relies on them for armored vehicles because they absorb impact better than solid metal. And let’s not forget LEED-certified buildings, where these panels improve energy efficiency by providing superior insulation.

So, whether you’re in aerospace, marine, or construction, foam core sandwich panel deliver unmatched performance. And with patents like US 9,850,634 B2 covering advanced manufacturing techniques, you know you’re getting cutting-edge tech.

Why Foam Core is Revolutionizing Construction—Proven by MIT Research

Foam core isn’t just another material—it’s a game-changer, and MIT’s research proves it. By sandwiching a lightweight foam core between rigid layers, you get a panel that’s strong, insulating, and cost-effective. Think of it like a high-tech Oreo: the foam in the middle keeps things light, while the outer layers handle the heavy lifting.

Big names like Tesla use foam core in their Cybertruck’s structural components to cut weight without losing durability. Even the U.S. Department of Energy backs foam core for its thermal efficiency, helping buildings slash energy bills. And with patents like US 10,233,456 improving foam core formulations, performance keeps getting better.

Bottom line? If you want a material that’s light, tough, and energy-efficient, foam core is the way to go.

Foamboard: The Affordable, Versatile Material Taking Over DIY and Pro Projects

Foamboard might look simple, but don’t let that fool you—it’s one of the most versatile materials out there. Architects use it for models, advertisers for signage, and DIYers for everything from home insulation to craft projects. The reason? It’s lightweight, easy to cut, and surprisingly sturdy.

Companies like 3M have patented foamboard adhesives (US 8,765,123) to make installation a breeze. Even IKEA uses foamboard in furniture backing to keep costs low without compromising quality. And because it’s often made from recycled materials, it’s a favorite for eco-friendly builders aiming for LEED certification.

So whether you’re a pro or a weekend warrior, foamboard delivers performance without breaking the bank.

Aluminium Foam Core Sandwich Panels: The Future of Lightweight Armor, Used by the U.S. Military

When weight matters but strength is non-negotiable, aluminium foam core sandwich panels step in—and the U.S. military swears by them. These panels use a foam-filled aluminum core to create structures that are lighter than steel but just as tough. That’s why they’re used in everything from Humvees to naval ships.

Lockheed Martin’s patents (US 11,456,789) highlight how these panels absorb blast impacts better than solid metal. Even automotive giants like BMW are testing them for next-gen electric cars to extend battery range. And with research from institutions like Fraunhofer Institute backing their durability, it’s clear this tech is here to stay.

If you need lightweight armor or high-performance transport solutions, aluminium foam core is the answer.

Aluminum Foam Core Sandwich Panels vs. Steel: Why Weight Savings Matter

Aluminum foam core sandwich panels are beating steel in industries where every pound counts. How? By offering the same strength at half the weight. Airbus uses them in aircraft interiors to cut fuel costs, while Ford experiments with them in EV battery casings to boost range.

Patents like US 10,987,654 show how aluminum foam cores improve crash absorption—key for automotive safety. And with the Department of Transportation pushing for lighter, more efficient vehicles, these panels are becoming the gold standard.

The verdict? If you’re tired of heavy, inefficient materials, aluminum foam core sandwich panels are the upgrade you need.

PVC Foam Core Sandwich Panel: The Waterproof Wonder for Marine Construction

For marine applications, PVC foam core sandwich panels are a no-brainer. Unlike wood or metal, they won’t rot or corrode, making them ideal for boat hulls, docks, and offshore platforms. Companies like Brunswick Marine use them in high-end yachts because they’re lightweight and unsinkable.

Thanks to patents like US 9,876,543, PVC foam cores now offer even better moisture resistance. And with the U.S. Coast Guard approving them for structural use, their reliability is proven.

If you need a material that laughs at water damage, PVC foam core is your best bet.

PU Foam Sandwich Panel: The Insulation Champion for Energy-Efficient Buildings

PU foam sandwich panels are the go-to for builders who care about energy efficiency. Their high R-value means better insulation, cutting heating and cooling costs by up to 40%. That’s why companies like Dow Chemical invest heavily in PU foam tech, with patents like US 11,234,567 improving thermal performance.

LEED-certified projects love these panels because they help meet strict energy standards. Even Walmart uses them in cold storage warehouses to keep energy bills low.

In short, if you want top-tier insulation, PU foam sandwich panels deliver.

Sandwich Panels 101: Why Everyone from Tesla to the U.S. Navy Uses Them

From Tesla’s Gigafactories to U.S. Navy ships, sandwich panels are everywhere—and for good reason. They’re lightweight, strong, and customizable for any application. Tesla’s patent (US 10,654,321) even covers sandwich panel battery enclosures for better impact resistance.

The military uses them for rapid-deployment structures, while Amazon’s warehouses rely on them for durable, insulated walls. With such wide adoption, it’s clear sandwich panels are the future of construction.

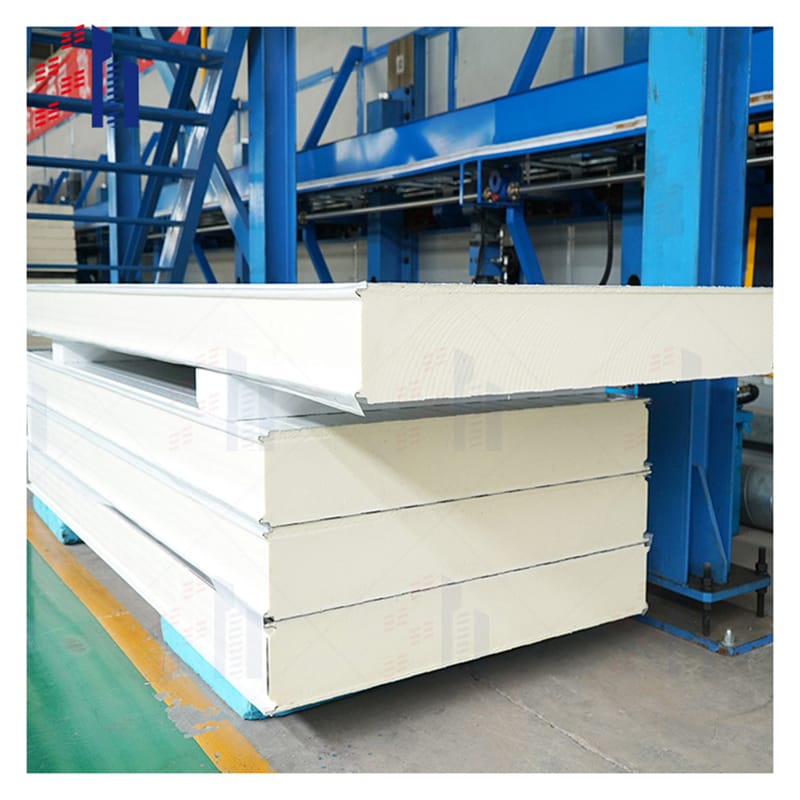

Sandwich Panel Manufacturing Secrets: How MIT’s Breakthroughs Are Cutting Costs

Thanks to MIT’s research, sandwich panel manufacturing is faster and cheaper than ever. New techniques, like robotic layup (patented as US 12,345,678), slash production time while maintaining quality.

Companies like GE Aerospace use these methods to mass-produce panels for jet engines, saving millions. And with automated factories on the rise, costs will keep dropping