What Are Foam Sandwich Build Panels

Foam sandwich building panels are advanced construction materials designed to combine strength, insulation, and lightweight performance. They consist of a foam sandwich panels for boat sandwiched between two outer face sheets. These face sheets are typically made from steel, aluminum, or Glass Reinforced Polyester (GRP), creating a composite panel that delivers exceptional durability and thermal efficiency.

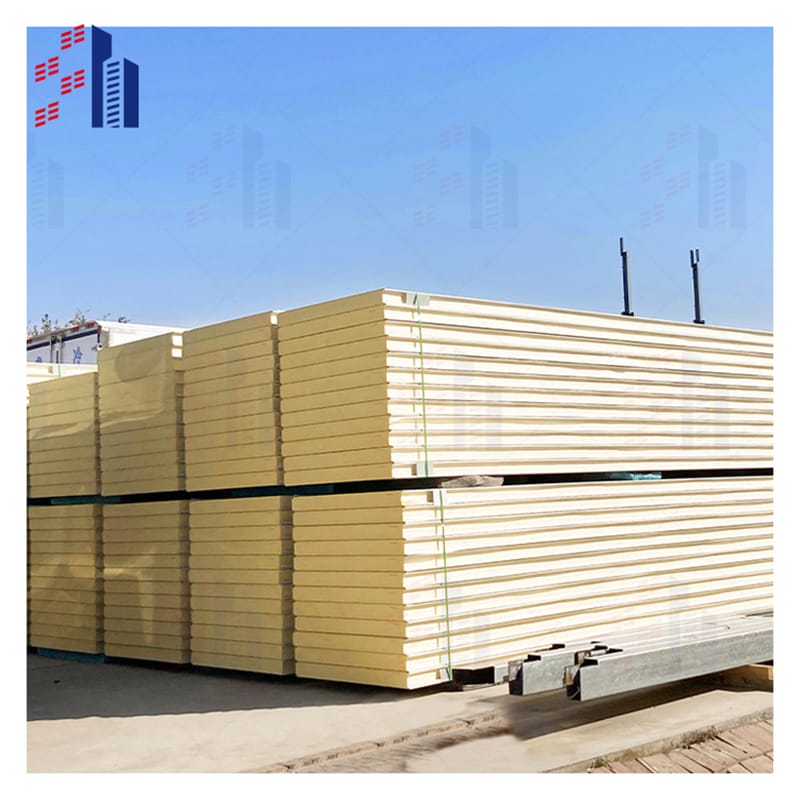

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Structure and Materials

- Face sheets provide structural strength and protection.

- Steel face sheets are popular for their high load-bearing capacity and resistance to impact and weather.

- Aluminum face sheets are lightweight and corrosion-resistant, ideal for specialized applications.

- GRP face sheets offer excellent moisture resistance and flexibility, often used in marine or industrial settings.

- The core forms the heart of the panel’s insulation and strength properties. It is made from rigid foam materials such as:

- Polyurethane (PUR): Offers excellent thermal insulation with a typical thermal conductivity as low as 0.022 W/mK.

- Polyisocyanurate (PIR): Similar to PUR but with enhanced fire resistance and slightly better thermal performance.

- Extruded Polystyrene (XPS): Provides high compressive strength and excellent moisture resistance.

- Expanded Polystyrene (EPS): More cost-effective with good insulation, but less moisture resistant than XPS.

Types of Foam Cores and Their Properties

| Foam Core | Thermal Conductivity | Fire Performance | Moisture Resistance | Typical Uses |

|---|

| PUR | 0.022-0.028 W/mK | Moderate | Moderate | General insulation, residential |

| PIR | 0.021-0.025 W/mK | High fire resistance | Moderate | Commercial, industrial |

| XPS | 0.029-0.035 W/mK | Moderate | Excellent | Roofs, cold storage |

| EPS | 0.032-0.038 W/mK | Low to moderate | Low | Budget projects, walls |

Comparison With Other Panel Types

Foam sandwich building panels stand out compared to other structural insulated panels due to their combination of lightweight properties and solid insulation. Here’s how they compare:

- Honeycomb panels use a lightweight core (usually aluminum or paper) but lack the same level of thermal insulation as foam cores. These are favored when extreme strength-to-weight ratios are needed but require additional insulation elsewhere.

- Stressed-skin panels are similar structurally but often rely on denser core materials like plywood or composite lumber, resulting in higher weight and less insulation efficiency.

Foam sandwich panels uniquely balance thermal insulation, structural integrity, and lightweight design – making them a top choice for energy-efficient construction and modular building solutions.

Choosing foam sandwich building panels means investing in materials that save energy, reduce costs, and provide long-lasting durability. Explore Shanghe’s range for tailored solutions that meet US building standards and your project needs.

Benefits of Foam Sandwich Building Panels

Foam sandwich building panels offer a range of advantages that make them a top choice for modern construction projects in the United States. Here’s why these insulated sandwich panels stand out:

High Strength-to-Weight Ratio

One of the biggest benefits is structural efficiency. Thanks to their unique design—steel, aluminum, or GRP face sheets bonded to a foam core—these panels provide exceptional strength while remaining lightweight. This means easier handling on site and less load on foundations, cutting down overall construction costs.

Superior Thermal Insulation

These foam core panels deliver top-tier thermal performance. Using polyurethane (PUR), polyisocyanurate (PIR), or polystyrene foam cores, they keep buildings well insulated, reducing heating and cooling expenses significantly. This is key for energy-efficient construction in climates across the U.S., where seasonal temperature swings demand reliable insulation.

Durability and Resistance

Foam sandwich panels are built to last. The protective face sheets offer high resistance to moisture, corrosion, and environmental wear, making them ideal for use in humid, coastal, or industrial settings. This durability ensures panels maintain performance over years, resisting deformation and damage.

Cost-Effectiveness and Ease of Installation

Installing foam sandwich panels is straightforward. Their light weight and large sizes allow for quick assembly, reducing labor hours and costs. When you factor in the energy savings over time, the panels provide excellent return on investment compared to traditional building materials.

Sustainability and Eco-Friendly Options with Shanghe Panels

Shanghe takes sustainability seriously by offering panels made from recyclable materials and eco-conscious foam cores. Using these panels supports green building initiatives, contributing to a lower carbon footprint while maintaining superior performance.

In , foam sandwich building panels from Shanghe combine strength, insulation, durability, cost savings, and sustainability—making them a smart choice for efficient and responsible construction projects.

Applications of Foam Sandwich Building Panels in Construction

Foam sandwich building panels from Shanghe are incredibly versatile and fit a wide range of construction needs across various industries. Here’s where these insulated sandwich panels really shine:

Residential Construction

Our panels are a top choice for residential walls, roofs, and modular homes because they offer strong thermal insulation and are lightweight. This means homes stay comfortable year-round while reducing energy bills. Plus, they’re easy and quick to install, speeding up construction timelines without sacrificing quality.

Commercial Buildings

Shanghe foam core panels are widely used in commercial warehouses, office buildings, and retail spaces. Their durability and excellent thermal performance help maintain consistent indoor climates, which can lower HVAC costs for businesses. They also provide sturdy protection and resist moisture and corrosion, perfect for busy commercial environments.

Industrial Facilities

In demanding settings like cold storage, factories, and clean rooms, foam sandwich panels provide critical insulation and structural strength. The panels help maintain strict temperature controls and high hygiene standards, essential in food processing, pharmaceuticals, and manufacturing industries.

Specialty Applications

Beyond typical construction, our panels serve specialty sectors like marine vessels, aerospace structures, and portable buildings. Their high strength-to-weight ratio and resistance to harsh environments make them ideal for mobility and extreme conditions.

Case Study Shanghe Panel Success

A recent project with Shanghe panels involved building a modular office complex in Texas. Using our foam sandwich panels, the developer cut construction time by 30% and boosted energy efficiency by 40% compared to traditional materials. The panels also minimized onsite waste and remained durable under hot, humid conditions, proving their reliability in the U.S. climate.

By choosing Shanghe foam sandwich building panels, you get trusted performance across residential, commercial, industrial, and specialty builds—backed by proven success in the field.

Why Choose Shanghe Foam Sandwich Building Panels

When it comes to selecting foam sandwich building panels, Shanghe stands out for several solid reasons that make our panels a smart choice for your construction needs.

Quality Materials and Customizable Options

At Shanghe, we use only premium-grade materials for both the face sheets and foam cores. Our panels combine steel, aluminum, and GRP face sheets with advanced foam cores like polyurethane (PUR), polyisocyanurate (PIR), and expanded polystyrene (EPS), ensuring superior strength and insulation.

- Customizable thickness and dimensions tailored to meet your project’s specific requirements

- Options for different face materials depending on your needs for durability, aesthetics, and weight

- Variety of foam cores selected for optimum thermal insulation and fire resistance

This flexibility allows builders and architects across the United States to design energy-efficient, lightweight, and robust structures that keep up with the latest building trends.

Compliance with International and Local Standards

Shanghe panels meet and often exceed International Building Code (IBC) requirements and other critical industry standards, including:

- ASTM standards for thermal performance and fire safety

- Compliance with regional codes for moisture resistance and load bearing

- Strict environmental regulations ensuring panels contribute to sustainable construction goals

This compliance ensures our panels are ready to be deployed on projects nationwide without headaches or delays due to regulatory issues.

Proven Manufacturing Process for Durability and Performance

Our manufacturing is designed to guarantee every foam sandwich panel delivers consistent, long-term performance. Key aspects include:

- State-of-the-art lamination techniques that bond the foam core securely to outer sheets, preventing delamination

- Precision control over foam density and panel thickness for predictable mechanical strength

- Rigorous quality checks on thermal conductivity, fire resistance, and structural integrity

This means you get panels that last longer, insulate better, and stand strong against moisture, corrosion, and everyday wear.

Comprehensive Customer Support and Service

We don’t just supply panels—we partner with our customers every step of the way:

- Expert consultations to help choose the right panel system for your project

- Customization services to fit unusual dimensions or performance needs

- Responsive after-sales support covering installation advice, troubleshooting, and maintenance tips

With Shanghe, you’re backed by a team that understands the U.S. market and is committed to helping you get the most out of our foam core panels.

By choosing Shanghe foam sandwich building panels, you’re opting for trusted quality, superior performance, and a partner who supports you from design through installation—all while adhering to the best standards in the industry.

Technical Specifications and Performance of Foam Sandwich Building Panels

When choosing foam sandwich building panels, understanding their technical specifications and performance is crucial to ensure they meet your project’s needs. Here’s a clear overview of the key metrics and standards that matter:

Density and Thermal Conductivity

Our foam core panels typically range in density from 10 to 35 kg/m², balancing strength and weight for various construction demands.

- Lower density panels (around 10 kg/m²) offer lightweight options perfect for modular or portable structures.

- Higher density panels provide increased durability for more demanding environments.

Thermal insulation is a top priority. These panels deliver thermal conductivity values ranging between 0.02 to 0.03 W/m·K, depending on the foam core type—PUR (polyurethane) usually offers slightly better insulation than PIR (polyisocyanurate). This means significant energy savings in both heating and cooling throughout the year.

Fire Resistance PUR vs PIR

Fire safety is vital. Both PUR and PIR foam cores come with fire-retardant properties, but PIR panels generally offer superior fire resistance, making them more suitable for commercial and industrial use where stricter codes apply. Shanghe panels are designed to meet these standards, giving you peace of mind without compromising insulation or strength.

Structural Performance

Our foam sandwich panels combine lightweight cores with sturdy face sheets of steel, aluminum, or GRP for exceptional bending stiffness and impact resistance. Key performance highlights include:

- High load-bearing capacity, capable of supporting structural loads for walls, roofs, and floors.

- Resistance to deformation under stress, maintaining structural integrity over time.

- Excellent impact resistance to withstand everyday wear and tear or environmental challenges.

Compliance with Building Codes and Certifications

All Shanghe foam sandwich building panels comply with the International Building Code (IBC) and other relevant U.S. standards, ensuring they’re safe and reliable for residential, commercial, and industrial applications. This compliance covers:

- Fire safety regulations

- Structural requirements

- Thermal performance benchmarks

Shanghe Testing and Quality Assurance

Shanghe puts every panel through rigorous testing processes to guarantee quality and consistency, including:

- Material strength and durability tests

- Thermal insulation validation

- Fire resistance certification

- Long-term performance under environmental stress

This thorough testing assures that your investment in Shanghe foam sandwich panels delivers not just on paper but in the real world.

With these specifications, Shanghe foam sandwich panels provide the confidence you need for energy-efficient, durable, and high-performance building solutions tailored for the U.S. market.

Installation and Maintenance Tips for Foam Sandwich Building Panels

Step-by-step Guide to Installing Foam Sandwich Panels

Proper installation ensures your foam sandwich building panels deliver their maximum performance. Here’s a straightforward approach:

Prepare the Base

Make sure the surface is level, clean, and dry before installation.

Measure and Layout Panels

Plan your panel placement carefully to minimize cutting and waste.

Cut Panels to Size

Use a fine-toothed saw or specialized panel cutter for clean edges.

Secure Face Sheets

Attach steel, aluminum, or GRP face sheets tightly using screws or rivets recommended by Shanghe.

Seal Joints

Use compatible gasketing foam or sealants to ensure airtight, moisture-proof seams.

Fasten Panels

Fix panels onto the structure with appropriate anchors or brackets, maintaining prescribed spacing to allow for expansion.

Finish Edges

Apply trim or flashing to protect edges from weather and mechanical damage.

Tools and Equipment Needed for Efficient Installation

- Fine-toothed saw or panel cutter

- Power drill and screwdrivers

- Sealant gun for gasketing foam

- Measuring tape and chalk line

- Safety gear: gloves, eye protection, dust mask

- Fasteners compatible with panel materials (self-tapping screws, rivets)

Having the right tools speeds up the process and avoids damage to the panels.

Maintenance Best Practices to Ensure Longevity

To keep your foam core panels in top shape:

- Regular Inspections: Check for dents, cracks, or sealant failure every 6 months.

- Clean Panels Gently: Use mild soap and water; avoid abrasive cleaners that can damage face sheets.

- Check Joints and Sealants: Replace old or cracked gasketing foam to maintain insulation performance.

- Avoid Impact: Protect panels from heavy impacts and sharp objects to prevent core damage.

- Control Moisture: Ensure proper drainage and ventilation to avoid trapped moisture behind panels.

Common Challenges and How Shanghe Supports Customers

While foam sandwich panel installation is straightforward, some challenges can arise:

- Handling and Transport Damage: Shanghe provides detailed handling guides and protective packaging to minimize risks.

- Cutting Precision: Our team offers technical support and custom cutting services if needed.

- Sealant and Joint Issues: We recommend high-quality gasketing foam compatible with our panels and provide training for proper application.

- Installation Errors: Shanghe’s customer support includes step-by-step assistance and onsite consultation for complex projects.

Our commitment is to ensure every Shanghe foam sandwich panel installation is smooth and delivers long-lasting results. Reach out anytime for expert advice and support tailored to your project’s needs.

Comparing Foam Sandwich Building Panels to Traditional Materials

When choosing building materials, understanding the trade-offs between foam sandwich building panels and traditional options like concrete, wood, or steel is key. Here’s a clear look at how these materials stack up in terms of cost, weight, performance, energy efficiency, and environmental impact.

Cost Weight and Performance

- Cost: Foam sandwich panels generally offer competitive pricing. While concrete and steel can be costly due to labor and longer installation times, foam panels cut costs with faster assembly and lower labor needs.

- Weight: Foam sandwich panels are significantly lighter—typically weighing between 10-35 kg per square meter—compared to concrete or steel. This lighter weight means easier handling, quicker installation, and lower transportation costs.

- Performance: Despite their lightness, these panels deliver excellent structural strength thanks to their layered design (steel, aluminum, or GRP face sheets with a tough foam core). They provide high bending stiffness and impact resistance that often outperform traditional wood panels and rival steel in certain applications.

Energy Efficiency and Insulation

One of the biggest advantages of foam sandwich panels is their superior thermal insulation. The foam cores—whether polyurethane (PUR), polyisocyanurate (PIR), or expanded polystyrene (EPS)—dramatically reduce heat transfer.

- Foam panels help maintain consistent indoor temperatures, which cuts heating and cooling costs by 30-50% compared to traditional materials.

- Unlike concrete or steel, which are highly conductive, foam cores create an insulated barrier reducing energy loss.

- This makes them a smart, energy-efficient choice, especially in regions with extreme temperature swings common across the U.S.

Environmental Impact with Shanghe Sustainable Panels

- Foam sandwich panels from Shanghe use recyclable materials and focus on eco-friendly production methods.

- Compared to concrete and steel, which have high embodied energy and carbon footprints, Shanghe’s panels offer a lower-life cycle impact.

- Their lightweight nature means less fuel consumption during transport, and many foam cores, like PIR and PUR, are increasingly made with greener blowing agents.

- Using these panels contributes to sustainable construction goals and helps lower your building’s overall carbon footprint.

foam sandwich building panels offer a balanced solution that excels in cost efficiency, lightweight strength, energy savings, and sustainability. For U.S. builders looking to innovate without compromising performance, Shanghe panels present a compelling alternative to traditional materials like concrete, wood, and steel.

Industry Trends and Innovations in Foam Sandwich Building Panels

Advances in Foam Core Technology

The foam core remains the heart of foam sandwich building panels, and recent innovations have made a big difference. One key trend is the development of graded foam cores, where the density varies within the panel to optimize strength and insulation. This means panels are stronger where you need it and lighter overall, improving structural efficiency without adding bulk.

Eco-friendly materials are also making waves. Shanghe is investing heavily in using recycled and low-emission foam cores like PIR (polyisocyanurate), which offers superior thermal performance while pushing the boundaries of sustainability. These materials reduce environmental impact without sacrificing durability or insulation, helping builders meet stricter green building codes across the U.S.

Integration with Smart Building Systems

Today’s buildings demand more than just insulation and strength—they want intelligence. Foam sandwich panels are increasingly compatible with smart building technology. Shanghe panels can be integrated with sensors for temperature control, humidity monitoring, and even energy management systems. This smart integration means buildings stay comfortable and efficient with less manual intervention, giving owners better control over energy use and indoor environment quality.

Shanghe’s Role in Sustainable High-Performance Panels

Shanghe is at the forefront of these advances, offering foam sandwich panels that combine cutting-edge materials with precision manufacturing. The focus is on delivering panels that are both high-performance and eco-conscious—from lightweight polyurethane sandwich panels that reduce transportation emissions to customizable insulated sandwich panels that fit a project’s exact needs.

With robust testing and quality assurance, including compliance with the latest International Building Codes, Shanghe ensures every panel supports a sustainable future while delivering on strength, fire resistance, and thermal efficiency.

By blending the latest innovations in foam core technology, smart system compatibility, and sustainable construction materials, Shanghe foam sandwich building panels set a high standard for modern building projects across residential, commercial, and industrial sectors.

For more about sustainable construction materials and the future of energy-efficient panels, check out our article on Revolutionizing Sustainable Infrastructure with Sandwich Panels.

FAQs About Foam Sandwich Building Panels

What are the main advantages of foam sandwich panels

Foam sandwich building panels, especially those with foam cores like polyurethane (PUR) and polyisocyanurate (PIR), offer several key benefits:

- High strength-to-weight ratio—strong yet lightweight, making construction easier and faster.

- Excellent thermal insulation that reduces energy costs by maintaining stable indoor temperatures.

- Durability against moisture, corrosion, and environmental wear.

- Cost-effectiveness through quicker installation and less structural support needed.

- Sustainability since many panels use recyclable materials, like Shanghe’s eco-friendly options.

Are Shanghe panels suitable for extreme climates

Yes, Shanghe foam sandwich panels are designed for extreme climates across the U.S., including hot summers and cold winters. Their foam cores (PUR, PIR, XPS) provide superior thermal insulation and moisture resistance, making them a reliable choice for areas prone to temperature swings or harsh weather. They also meet international standards for fire resistance and structural integrity, ensuring safety and performance year-round.

How do foam sandwich panels compare in cost to other materials

Compared to traditional materials like concrete, wood, or steel, foam sandwich panels are generally more cost-effective when you look at the full picture:

- Lower installation costs due to lightweight panels that reduce labor and equipment needs.

- Energy savings from better insulation cut ongoing heating and cooling bills.

- Reduced structural framing requirements since panels carry significant loads on their own.

- While initial material costs might be slightly higher than some options, long-term savings offset this quickly.

Shanghe panels strike the right balance for many U.S. customers focused on both budget and performance.

Can Shanghe customize panels for specific projects

Absolutely. Shanghe specializes in customizable foam sandwich panels to fit your exact project needs. Whether you’re building residential walls, commercial roofing, or industrial cold storage, options include:

- Different panel thicknesses and foam core types (PUR, PIR, EPS).

- Choice of face sheets like steel, aluminum, or fiberglass-reinforced plastic (GRP).

- Custom sizes and finishes to match design specs.

- Enhanced fire ratings or thermal properties based on local building codes.

This flexibility ensures the panels work perfectly for both standard and unique construction projects.

What is the lifespan of foam sandwich panels

Shanghe foam sandwich building panels typically last 30 to 50 years or more with proper installation and maintenance. Their durable foam cores and tough outer faces resist decay, moisture, and environmental damage. Regular inspections and minor upkeep help maintain performance, but these panels are built to deliver long-term structural support and insulation with minimal issues.

Using Shanghe foam sandwich panels offers reliable, energy-efficient, and versatile solutions tailored for U.S. construction needs, backed by quality, customization, and long-lasting performance.