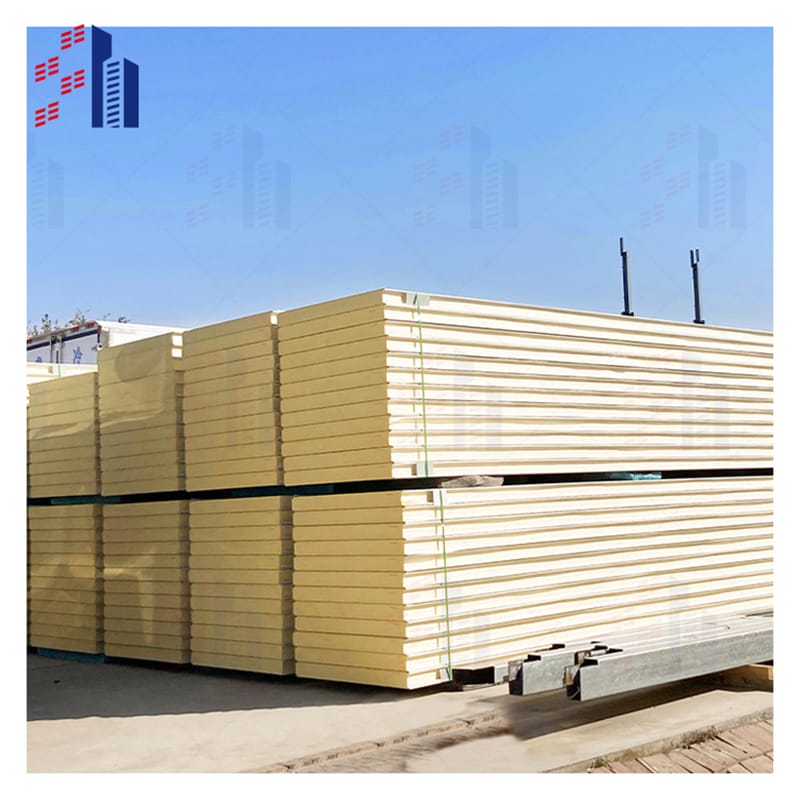

Foam sandwich wall panels are advanced composite structures designed for superior insulation, strength, and lightweight construction. These panels consist of three essential components:

- Core Material: The inner foam core provides thermal insulation and structural rigidity. Common foams include polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), and mineral wool. Each core type balances insulation value, fire resistance, and cost differently.

- Face Materials: The outer layers, or facings, are typically made from durable metal sheets like galvanized steel or aluminum, fiberglass, or other composite materials that protect the core and provide mechanical strength.

- Bonding Techniques: The core and face materials are bonded with high-strength adhesives under controlled pressure and temperature. This lamination process ensures a unified panel with excellent structural integrity and minimal thermal bridging.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

At Shanghe, we take this one step further by combining selective materials and proprietary bonding methods tailored to the needs of modern building environments. Our foam sandwich wall panels factory emphasizes a perfect balance of lightweight design without sacrificing durability or thermal efficiency.

Shanghe’s unique approach includes:

- Customizing panel thickness and core types for specific climate and application demands

- Using premium adhesives for long-lasting bonding in all weather conditions

- Ensuring compliance with global standards for fire safety, energy efficiency, and structural performance

These panels are more than just a construction material—they are engineered solutions that streamline installation, reduce building costs, and enhance energy efficiency in residential, commercial, and industrial projects.

Explore our range of EPS sandwich panels and other specialized foam sandwich options designed to meet your project’s specific requirements.

Benefits of Foam Sandwich Wall Panels

Excellent Energy Efficiency and Thermal Insulation

Foam sandwich wall panels are highly energy-efficient, thanks to their superior thermal insulation properties. Using core materials like polyurethane (PU) or expanded polystyrene (EPS), they significantly reduce heat transfer. This keeps buildings warmer in winter and cooler in summer, cutting down on HVAC costs and boosting overall energy savings.

Lightweight and Strong with an Impressive Strength-to-Weight Ratio

One of the biggest advantages is their lightweight nature combined with high strength. These panels offer a strong-to-weight ratio that makes handling, transportation, and installation easier compared to traditional materials like concrete or brick. This also reduces structural load on buildings without compromising durability.

Cost-Effective Construction Solution

Choosing foam sandwich wall panels means cutting costs on multiple fronts. Their ease of installation reduces labor time and expenses. Additionally, their durability minimizes maintenance and replacement costs long-term. For U.S. customers, this translates into smart investments without hidden fees.

Fire and Sound Insulation Benefits

Shanghe’s foam sandwich panels provide effective fire resistance and sound insulation. Panels with mineral wool or polyisocyanurate (PIR) cores meet strict fire safety standards, making them ideal for commercial and industrial projects. Plus, thicker panels reduce noise transmission, enhancing indoor comfort.

Sustainability and Eco-Friendliness

Shanghe designs these panels with environmental responsibility in mind. They use recyclable, eco-friendly materials, contributing to sustainable building practices. Their long lifespan and minimal waste production align perfectly with U.S. green building certifications like LEED.

Durable, Aesthetic, and Code Compliant

Beyond performance, these panels provide lasting durability and clean aesthetics that suit both residential and commercial needs. Shanghe ensures their products comply with international standards and local building codes, giving you peace of mind regarding safety and quality.

By choosing Shanghe foam sandwich wall panels, you gain a product that blends energy savings, strength, cost efficiency, and sustainability — perfect for today’s building demands in the United States.

Applications of Foam Sandwich Wall Panels

Foam sandwich wall panels are highly versatile, making them a top choice for a broad range of construction projects across residential, commercial, and industrial sectors. Their unique combination of insulation, durability, and lightweight construction opens doors to multiple uses.

Construction Walls Roofs and Partitions

These insulated sandwich panels are widely used for exterior and interior walls, roofs, and partitions due to their excellent thermal insulation and structural strength. They help maintain temperature control and reduce energy costs in buildings while speeding up the construction process thanks to their ease of installation.

- Residential: Ideal for modern homes demanding energy efficiency and design flexibility.

- Commercial: Perfect for offices, shopping centers, and public buildings looking for durable and fire-resistant wall solutions.

- Industrial: Used in factories and warehouses where insulation and structural integrity are essential.

Specialized Industrial Applications

Foam sandwich wall panels made with materials like PIR foam or mineral wool are perfect for sectors needing specialized performance:

- Cold Storage and Warehousing: These panels provide superior thermal insulation to maintain controlled environments.

- Automotive: Lightweight panels help optimize vehicle manufacturing by reducing overall weight without compromising strength.

- Marine: Panels designed to withstand moisture and corrosion are chosen for yacht and ship interiors.

Case Study Shanghe Panels in Commercial Projects

Shanghe foam sandwich panels have been successfully integrated into multiple commercial projects, showcasing their adaptability and performance. For example, in a recent commercial facility project, Shanghe’s polyurethane foam sandwich panels delivered outstanding thermal insulation and fire resistance while maintaining a sleek and modern aesthetic. The result was a building with lower energy consumption and faster construction times, proving the panels’ real-world value.

Explore our range of polyurethane foam sandwich panels and rockwool sandwich panels to find the best fit for your specific construction needs.

Types of Foam Sandwich Wall Panels Offered by Shanghe

Shanghe offers a range of foam sandwich wall panels tailored to fit diverse construction needs across the U.S. market. Each panel type combines core materials and face sheets designed for specific performance goals like thermal insulation, fire resistance, acoustic control, and cost efficiency.

Polyurethane Foam Sandwich Panels

Shanghe’s polyurethane (PU) panels deliver excellent thermal insulation thanks to their low thermal conductivity. These panels help reduce heating and cooling costs and are ideal for energy-efficient residential and commercial buildings. They’re lightweight yet strong, making installation quicker and easier.

Polyisocyanurate Foam Panels PIR

Known for enhanced fire resistance and improved thermal stability, Shanghe’s polyisocyanurate (PIR) panels are perfect for applications demanding higher safety standards. They offer excellent insulation performance with better fire ratings compared to standard polyurethane panels.

Expanded Polystyrene EPS Sandwich Panels

For clients prioritizing cost-effectiveness without sacrificing quality, the EPS panels offer a budget-friendly solution. These panels are lightweight and provide solid thermal insulation, commonly used in large-scale commercial projects and residential walls or roofs requiring fast deployment.

Mineral Wool Foam Sandwich Panels

Shanghe’s mineral wool panels stand out for their strong acoustic dampening properties and superior fire performance. Mineral wool cores naturally resist high temperatures and provide sound insulation, making these panels a prime choice for industrial use and buildings located in noisy environments.

Customization Options

Understanding that every project has its own requirements, Shanghe offers extensive customization on:

- Thickness options to match specific insulation or structural needs

- Finishes ranging from smooth to textured surfaces

- Colors tailored to design schemes or brand aesthetics

This level of customization ensures that U.S. builders and architects can confidently meet local building codes and client preferences without compromise.

With Shanghe’s variety of foam sandwich wall panels, you can expect high performance in thermal insulation, fire safety, lightweight strength, and acoustic control along with flexible options that meet modern construction demands.

Why Choose Shanghe Foam Sandwich Wall Panels

When it comes to foam sandwich wall panels, Shanghe stands out as a top choice for the U.S. market thanks to its strong focus on quality manufacturing and strict quality control. Every panel leaving the factory meets rigorous standards to ensure durability, performance, and consistency, giving you peace of mind on your projects.

Quality Manufacturing and Standards

Shanghe uses advanced production techniques and high-grade materials to create panels with superior thermal insulation, fire resistance, and structural strength. Our polyurethane wall panels, PIR foam panels, EPS sandwich panels, and mineral wool panels undergo thorough testing to meet and exceed global compliance and international standards widely recognized in construction across the U.S. This compliance guarantees safe, reliable, and energy-efficient building solutions.

Sustainability Commitment

We know that sustainability is vital in today’s construction landscape. That’s why Shanghe panels are designed with eco-friendly, recyclable materials that reduce environmental impact without sacrificing performance. Our focus on sustainable building materials ensures your projects contribute to greener, healthier environments — a key selling point for modern American consumers and businesses.

Comprehensive Customer Support

Choosing Shanghe means more than just buying a product — it’s gaining a partner. We provide professional consultation to help you select the right type of insulated sandwich panels for your specific needs, whether it’s for residential, commercial, or industrial use. Our team also offers expert advice on installation best practices and dependable after-sales service, making your project smoother from start to finish.

Contact Shanghe Today for Quotes and Samples

Ready to experience the benefits of Shanghe foam sandwich wall panels? Contact us for a detailed quote or to request samples. Our solutions are tailored for U.S. construction demands, offering lightweight construction panels that boost efficiency, cut energy costs, and meet the highest quality expectations.

Choose Shanghe for trusted, sustainable, and high-performance foam sandwich wall panels.

Installation and Maintenance Tips for Foam Sandwich Wall Panels

Installing and maintaining foam sandwich wall panels correctly ensures maximum performance, durability, and energy efficiency. Here’s a straightforward guide tailored for users in the United States looking to optimize their insulated sandwich panels.

Step by Step Installation Guide for Foam Sandwich Wall Panels

- Site Preparation Ensure the structure’s frame is clean, level, and properly aligned. Check all measurements twice to match panel sizes. Panel Handling Handle panels carefully to avoid damaging the surfaces or edges. Store panels off the ground and covered when not in use to prevent moisture damage. Positioning and Fixing Panels Start installing panels from the bottom or corner, aligning edges precisely. Use recommended fasteners like self-tapping screws or anchors suitable for the substrate (metal, wood, concrete). Apply foam or compatible adhesive between joints for airtight sealing and better thermal insulation. Sealing and Finishing Seal panel joints with appropriate weatherproof and fire-resistant sealants. Install trims or flashing to protect edges and improve aesthetics. Inspect for any gaps or misalignment before completion. Compliance Checks Follow manufacturer guidelines plus local US building codes for fire safety and insulation standards. Confirm panels meet energy code requirements depending on the state. Maintenance Best Practices for Foam Sandwich Wall Panels Regular Visual Inspections

Check panels for cracks, dents, sealant wear, or water infiltration quarterly.

Cleaning

Wash panels with mild detergent and water to prevent dirt buildup without damaging finishes.

Sealant Inspection

Inspect sealants yearly and reseal any cracks to maintain fire resistance and thermal insulation.

Fastener Tightness

Re-tighten loose screws or fasteners during routine checks to avoid panel movement and air leaks.

Address Damage Immediately

Repair or replace panels with significant damage to prevent insulation loss or moisture issues.

Common Installation Challenges and Solutions

Panel Warping or Misalignment

Ensure proper storage and careful handling; double-check frame alignment before mounting panels.

Air and Moisture Leaks at Joints

Use high-quality foam adhesive and fire-resistant sealants to fill gaps and avoid thermal bridging.

Improper Fastening

Use fasteners recommended by Shanghe and avoid over-tightening that can damage the panel core.

Shanghe Support for Installation and Maintenance

When you choose Shanghe foam sandwich wall panels, you get more than just top-quality materials:

Expert Consultation

Our team offers professional advice on panel selection, preparation, and installation tailored to your project and local climate.

Detailed Installation Manuals

We provide clear, step-by-step guides specific to each panel type, making the process smoother and faster.

After-Sales Service

Reach out anytime for support with repairs, material questions, or replacement parts to keep your panels performing at their best.

Using Shanghe’s foam sandwich wall panels with proper installation and maintenance means you’ll enjoy energy-efficient wall panels with reliable performance for years to come without costly repairs or replacements.

Comparing Foam Sandwich Wall Panels to Traditional Materials

When it comes to building materials, foam sandwich wall panels offer several clear advantages over traditional options like concrete, brick, and timber. Here’s a detailed look at how these panels stack up in the U.S. market, especially focusing on Shanghe’s products.

Cost and Weight Efficiency

- Lightweight Construction: Foam sandwich panels are significantly lighter than concrete and brick walls, making them easier and faster to handle on site. This reduces the need for heavy-duty equipment and speeds up installation.

- Lower Transportation Costs: Due to their lightweight nature, shipping and handling costs drop, which adds up in large-scale projects.

- Cost Savings: While the initial material cost can be competitive or slightly higher than traditional materials, savings in labor, installation time, and long-term energy bills make foam sandwich panels a cost-effective choice overall.

Energy Savings and Thermal Performance

- Superior Insulation: Unlike brick or timber, Shanghe foam sandwich wall panels integrate advanced core materials like polyurethane or PIR foam, providing excellent thermal insulation. This reduces heating and cooling costs, delivering noticeable energy savings over time.

- Data-Backed Efficiency: Studies show buildings using insulated sandwich panels cut energy consumption by up to 30% compared to traditional walls — a critical factor in regions with extreme weather variations.

Installation Speed and Labor Efficiency

- Quick Installation: Foam sandwich panels come pre-finished and ready to install, slashing construction timelines dramatically when compared with laying brick or building timber frames.

- Reduced Labor: The panels can be installed by smaller crews with less specialized skills, cutting labor costs and minimizing delays.

Durability and Longevity

- Moisture Resistance: Unlike timber, the foam core and coated face materials resist rot, mold, and water damage.

- Structural Strength: Despite being lightweight, these panels provide excellent strength-to-weight ratios, standing up well against impact and weathering.

- Fire Resistance: With options like PIR and mineral wool cores, Shanghe fire-resistant wall panels comply with strict safety standards, offering better performance than untreated wood or certain bricks.

Why Shanghe Panels Outperform Traditional Materials

- Tailored Solutions: Shanghe offers a range of foam sandwich panel types—including polyurethane, PIR, EPS, and mineral wool—to match project needs.

- Sustainability Focus: Their panels are designed to be recyclable and use eco-friendly materials, aligning with growing demands for green construction in the U.S.

- Compliance and Quality: Manufactured with strict quality controls and meeting global standards, Shanghe panels provide reliable, long-lasting results you can trust.

- Enhanced Aesthetics: Unlike traditional rough surfaces, these panels come with customizable finishes and colors, adding design flexibility for modern builds.

foam sandwich wall panels from Shanghe offer superior cost efficiency, energy savings, faster installation, and durability compared to concrete, brick, or timber. For U.S. builders and homeowners prioritizing performance and sustainability, these panels are a smart, future-ready choice.

Industry Trends and Market Insights on Foam Sandwich Wall Panels

The construction industry in the United States is rapidly shifting towards energy-efficient and sustainable building materials, making foam sandwich wall panels a top choice. Thanks to their excellent thermal insulation, lightweight structure, and eco-friendly components, these panels address the growing demand for energy-efficient wall panels that reduce heating and cooling costs while meeting stricter environmental standards.

Growing Demand and Market Forecast

The market for foam sandwich wall panels is projected to grow at a strong compound annual growth rate (CAGR) over the next several years. This growth is driven by factors such as:

- Increasing energy codes and regulations pushing for better thermal insulation panels

- Growing emphasis on reducing carbon footprints through sustainable building materials

- The rise of lightweight construction methods for faster and more efficient building

This upward trend highlights the shift from traditional materials like brick and concrete to advanced, insulated sandwich panels that offer superior performance and lower life cycle costs.

Shanghe’s Innovation and Market Leadership

Shanghe stands out as a leader in this evolving market by consistently innovating and aligning with the U.S. construction sector’s needs. Their product range—including polyurethane, PIR foam panels, EPS sandwich panels, and mineral wool panels—is designed to balance energy efficiency, fire resistance, and acoustic performance without compromising strength or sustainability.

Key points about Shanghe’s role:

- Integrating eco-friendly and recyclable materials to meet stringent environmental guidelines

- Offering customized solutions that comply with international standards and U.S. codes

- Utilizing advanced bonding techniques for durability and ease of installation

- Supporting customers with expert consultation, making the switch to foam sandwich panels straightforward and cost-effective

With strong market demand fueled by energy efficiency needs and sustainability goals, foam sandwich wall panels are set to grow rapidly in the U.S. construction market. Shanghe’s leadership and innovation ensure that customers have access to high-quality, compliant, and customized panels that meet the challenges of modern building projects. Investing in these advanced panels means staying ahead in a market that prizes performance, speed, and environmental responsibility.

Frequently Asked Questions about Foam Sandwich Wall Panels

Fire Safety Features of Foam Sandwich Wall Panels

Fire resistance is a top concern when choosing wall panels. Shanghe foam sandwich wall panels offer enhanced fire safety thanks to their carefully selected core materials like polyisocyanurate (PIR) and mineral wool, which are naturally fire-resistant. Many of our panels meet or exceed international fire safety standards, making them suitable for residential, commercial, and industrial projects across the U.S. The fire-retardant coatings and bonding techniques we use further improve flame resistance, giving you peace of mind.

Energy Efficiency Contributions

Our foam sandwich wall panels are specifically designed to deliver superior thermal insulation. Materials such as polyurethane (PU) and expanded polystyrene (EPS) cores provide excellent heat retention, dramatically reducing energy costs and improving HVAC efficiency. This makes them ideal for energy-efficient buildings and green construction. The panels also minimize heat bridges thanks to their continuous insulation layers, which enhances overall building envelope performance in both hot and cold climates.

Customization Options for Foam Sandwich Wall Panels

We understand every project has unique needs. Shanghe offers a variety of customization options, including:

- Thickness ranging from 1 inch up to 6 inches or more for tailored insulation values

- Choice of core materials (PU, PIR, EPS, mineral wool) based on your priorities (thermal, fire, sound)

- Multiple face materials like steel, aluminum, or composite sheets

- Various finishes and colors to match architectural styles and branding needs

Our panels can be custom cut or fabricated to fit specific dimensions, improving installation speed and reducing waste.

Suitability for Extreme Weather Conditions

Shanghe foam sandwich wall panels are built to stand up to the extreme weather challenges common in the United States—from scorching heat in the Southwest to freezing winters in the North. Their lightweight yet durable construction resists damage from wind, rain, and temperature fluctuations. The excellent thermal insulation helps maintain interior comfort regardless of outside conditions, while the moisture-resistant properties protect against mold and structural degradation. This makes the panels well suited for use in harsh climates, including coastal and high-humidity areas.

If you have other questions about fire resistance, energy efficiency, customization, or weather suitability, contact us. Shanghe is here to help you choose the right foam sandwich wall panels tailored to your project’s demands.