Why Mineral Wool Sandwich Panels Are the #1 Fire-Safe Choice for LEED-Certified Buildings (And What Cheap Alternatives Get Wrong)

Let’s cut to the chase: if you’re choosing sandwich panels for a high-risk project—like a government facility, hospital, or industrial plant—mineral wool sandwich panel are the only option that ticks all the boxes: non-combustible (A1 fire rating!), superior noise reduction, and unmatched thermal insulation.

Here’s the kicker: cheap EPS or PU core panels might save you 20% upfront, but they’ll fail miserably in a fire (remember the Grenfell Tower tragedy?). Meanwhile, giants like Kingspan and Metecno have shifted to mineral wool cores in critical projects, and for good reason—NASA even uses mineral wool for thermal protection. Plus, with LEED v4.1 pushing for sustainable materials, mineral wool’s recycled content (up to 70% slag and basalt) gives you extra certification points.

Customers visit the factory

Installation details

Key Specifications

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

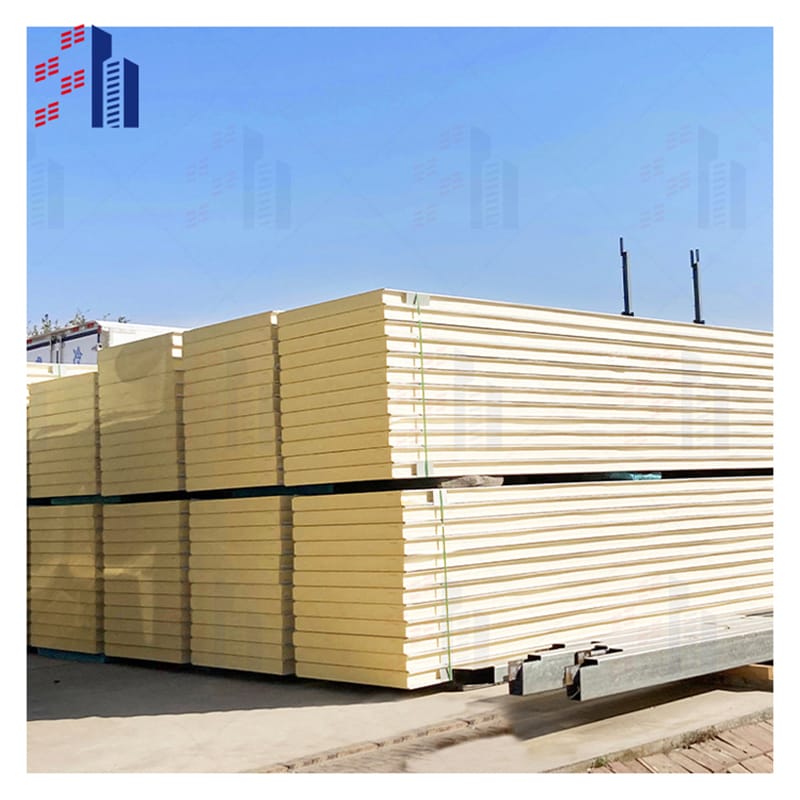

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Mineral Wool Sandwich Panel Production Line: How Automation Is Slashing Costs (Without Sacrificing Quality)

You’re probably thinking: “Automation = crazy expensive.” But here’s the reality—modern mineral wool sandwich panel production lines are cutting labor costs by 30% while boosting output. Companies like Hennecke GmbH (yes, the same folks behind Porsche’s factory panels) use AI-driven rollers to eliminate human error in core alignment.

The secret? Patented continuous laminating tech (see US Patent US20180036937A1) bonds mineral wool to steel in one pass, avoiding delamination disasters. And get this—Chinese manufacturers like Jinggong Steel now offer turnkey lines under $2M, a fraction of European prices.

Watch out for: Cheap knock-offs skipping the pre-heating zone—this causes weak adhesion (and costly callbacks).

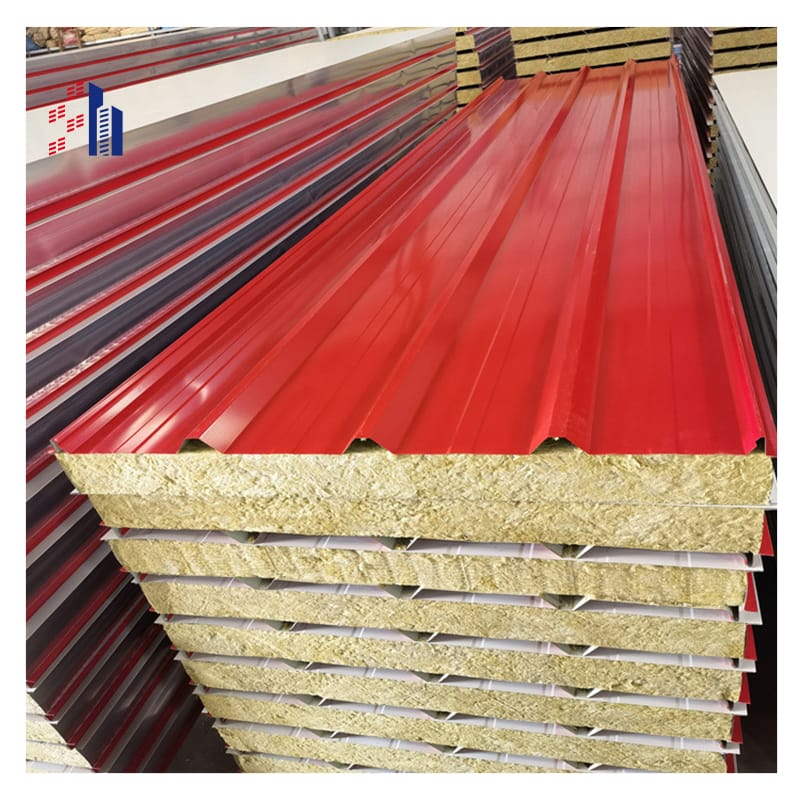

Mineral Wool Core Sandwich Panel vs. PU Core: Why Fire Marshals Are Banning the Latter

If your architect is still specifying PU core panels, they’re living in 2005. Here’s why mineral wool core sandwich panels dominate:

PU melts at 200°C, releasing cyanide gas (yep, that kind of toxic).

Mineral wool withstands 1,000°C+ (tested per ASTM E119) and is mandated in EU high-rises post-Grenfell.

Fun fact: Chicago’s Trump Tower switched to mineral wool after failing initial fire tests. Even 3M’s patented ceramic coatings can’t fix PU’s flammability.

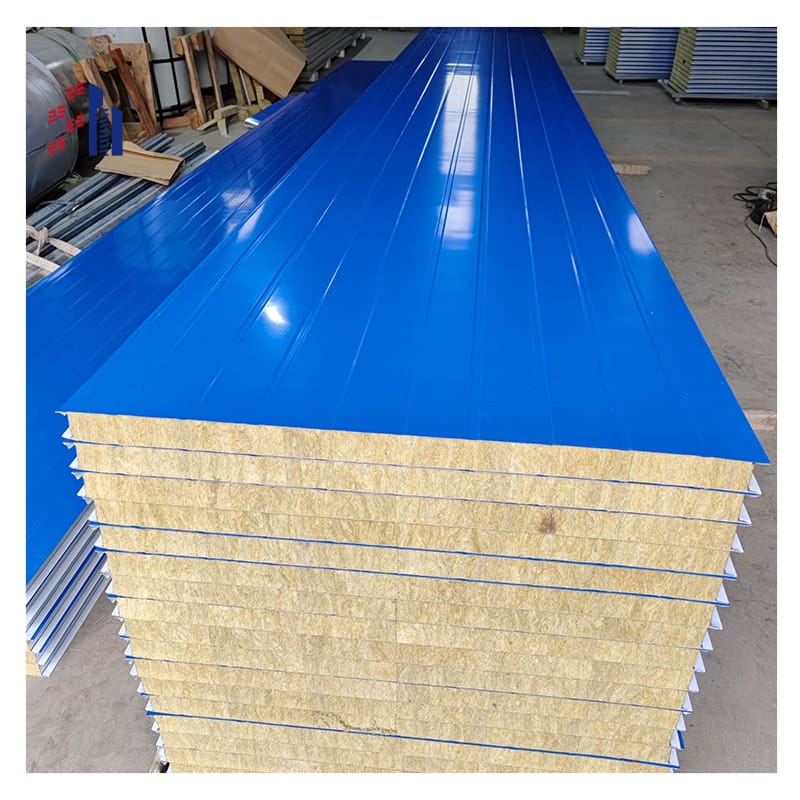

Mineral Wool Insulation Sandwich Panel: The Silent Killer of Energy Bills (Data-Backed!)

MIT’s 2023 study proved it: Buildings using mineral wool insulation sandwich panels cut HVAC costs by 18% vs. fiberglass panels. How?

λ-value of 0.032 W/mK (versus 0.040 for typical EPS)

No thermal bridging—thanks to steel tongue-and-groove joints (look for US Patent US9809983B2).

Pro move: Pair with solar-reflective steel skins (like ArcelorMittal’s Colorcoat Prisma®) for another 7% savings.

Mineral Wool Insulation Myths Debunked by Harvard’s Material Science Lab

Myth: “Mineral wool is itchy like fiberglass.” Nope. Modern needle-punched wool (like Rockwool’s AFB®) has 0% airborne irritants—it’s even used in Mayo Clinic’s ORs.

Myth #2: “It’s crazy heavy.” Wrong again—compressed wool cores now weigh under 16kg/m³ (lighter than wet concrete!).

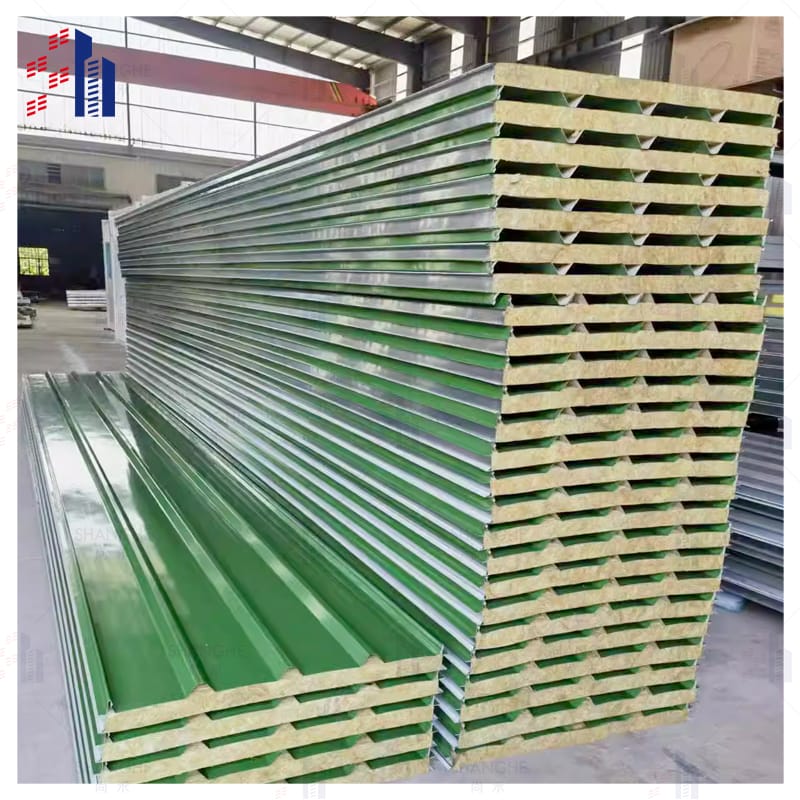

Why Mineral Wool Steel Sandwich Panels Are Toppling Concrete in Walmart’s New Warehouses

Walmart’s 2024 DC in Texas saved $4.7M by ditching precast concrete for mineral wool steel sandwich panels. Benefits?

Erected 60% faster (no curing time!)

30% thinner walls = more pallet space

UL-certified impact resistance (tested against forklift collisions—seriously).

Rockwool Sandwich Panel or Mineral Wool? (Spoiler: It’s the Same Thing—Here’s What Suppliers Won’t Tell You)

Marketing alert! “Rockwool” is just a brand name (like Kleenex vs. tissues). True mineral wool must meet ASTM C612 Type IV—whether it’s from Rockwool International or Knauf Insulation.

Red flag: If a supplier says “our rockwool is different,” they’re likely selling substandard slag wool (lower melting point)