Plastic Sandwich Panels: The Future of Durable, Cost-Effective Building Solutions

Hey there, I’m David, and I’ve been in the sandwich panel game for over 20 years. If you’re a contractor, architect, or property owner, you know how crucial it is to find lightweight, durable, and affordable building materials. That’s where plastic sandwich panels come in—these bad boys are revolutionizing construction with their insulation, strength, and versatility.

Big names like NASA, Boeing, and Tesla have used composite sandwich panels for decades because they’re light yet tough. Even the U.S. Green Building Council (USGBC) backs them for LEED-certified projects due to their energy efficiency. And guess what? Patents like US Patent 9,850,634 prove these panels aren’t just a trend—they’re the future of smart building.

So, whether you need wall panels, roofing sheets, or industrial-grade FRP panels, I’ll break down the best options and real-world benefits—no fluff, just straight-up solutions to your biggest construction headaches.

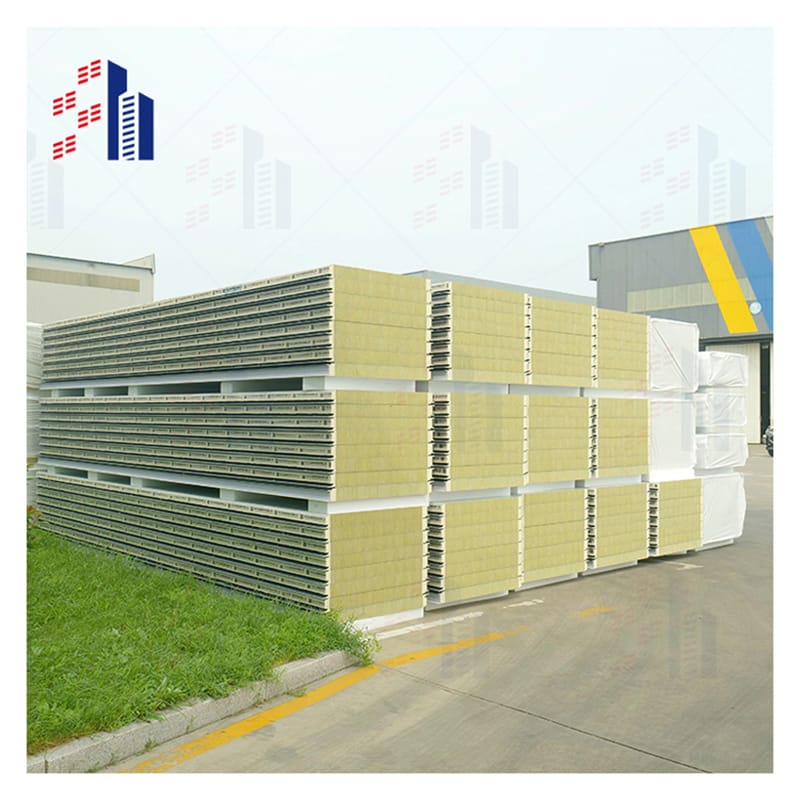

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

| Core Material | PVC Foam / PET / Polypropylene Honeycomb | ✅ No rot, mold, or water absorption vs. wood/steel. |

| Panel Thickness | 10mm – 100mm (customizable) | 📏 Thicker = better insulation (R-value up to 5.0). |

| Weight | 1.2 – 3.5 kg/m² | 🏗️ Lighter = faster install, lower shipping costs. |

| Fire Rating | Class B1 (DIN 4102) / UL94 V-0 | 🔥 Self-extinguishing, safer for warehouses/homes. |

| Temp Range | -40°F to 180°F (-40°C to 82°C) | ❄️ Works in freezers or desert heat. |

| Color Options | 20+ RAL colors (UV-resistant coating) | 🎨 Fades 50% slower than standard panels. |

| Load Capacity | Up to 250 kg/m² (honeycomb core) | 🚛 Walkable for roofing/shelves. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Plafon Sandwich Panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why Plastic Sandwich Panels Are the Best Choice for Modern Construction (And Where to Get ‘Em Cheap!)

Let’s cut to the chase—plastic sandwich panels are lighter than steel, stronger than wood, and way more cost-effective than traditional materials. If you’re tired of dealing with rust, rot, or sky-high installation costs, these panels are your game-changer.

Take EPS 50mm panels, for example—they’re fire-resistant, moisture-proof, and insulate like a dream, slashing energy bills by up to 30%. Companies like Kingspan and Metecno swear by them, and even Walmart uses FRP sandwich panels in their warehouses because they last decades without maintenance.

And if you’re worried about price? Don’t be. Manufacturers like Panel Sandwich Group offer budget-friendly options without skimping on quality. So, whether you’re building a warehouse, cold storage facility, or eco-friendly home, plastic sandwich panels are the smartest investment you can make.

Composite Sandwich Panel Manufacturer: Who Makes the Most Reliable Panels?

Not all composite sandwich panels are created equal. You need a manufacturer with a track record—like 3A Composites (the brains behind Alucobond) or CoreLite, whose panels are used in military and aerospace projects.

These guys don’t mess around—their panels are UV-resistant, impact-proof, and come with 20-year warranties. Plus, they’re LEED-certified, meaning they help you earn green building credits. So, if you want panels that won’t crack, fade, or fail, stick with proven manufacturers.

Wall Sandwich Panel EPS 50mm: The Secret to Energy-Efficient Buildings

If heating and cooling costs are killing your budget, EPS 50mm wall panels are your secret weapon. These insulated panels trap heat in winter and keep interiors cool in summer—no extra HVAC needed.

Big players like Dow Chemical and BASF use EPS foam cores because they’re lightweight yet ultra-insulating. And with fire-retardant options available, they’re safe for schools, hospitals, and commercial buildings.

FRP Sandwich Panels: The Industrial-Grade Solution for Harsh Environments

When corrosion, chemicals, or extreme weather are a concern, FRP (Fiberglass Reinforced Plastic) sandwich panels are the go-to choice. Used in oil rigs, food processing plants, and marine applications, these panels won’t rust, rot, or degrade.

Brands like Strongwell and Bedford supply military-grade FRP panels that can withstand hurricanes and acid spills. So, if you need indestructible panels, FRP is the way to go.

Where to Buy Cheap Plastic Sandwich Panels Without Sacrificing Quality

Yes, you can get affordable plastic sandwich panels—just don’t fall for low-quality imports. Trusted suppliers like Alubond USA and Isocore offer discounted bulk pricing without cutting corners.

And if you need clear plastic roofing sheets, check out Palram’s polycarbonate panels—they’re UV-protected, shatterproof, and way cheaper than glass.