Plywood foam sandwich panels are advanced composite panels designed with a foam core bonded between two durable plywood skins. This construction creates a lightweight yet strong panel that offers an excellent strength-to-weight ratio. The foam core acts as the insulation and structural support, while the plywood facings provide surface durability and rigidity. These panels stand out as a smart alternative to traditional plywood and other composite products like structural insulated panels (SIPs) or fiber-reinforced boards.

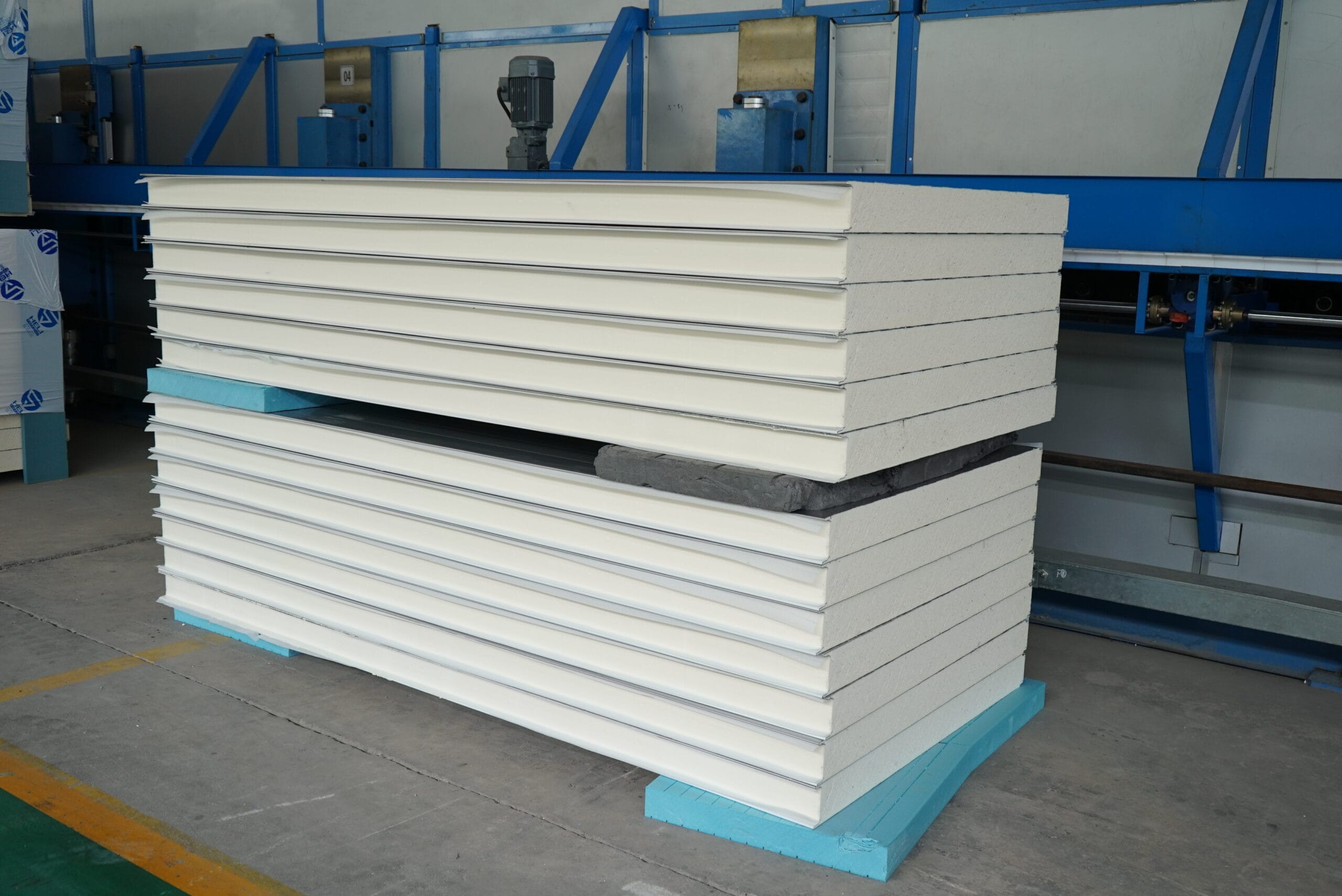

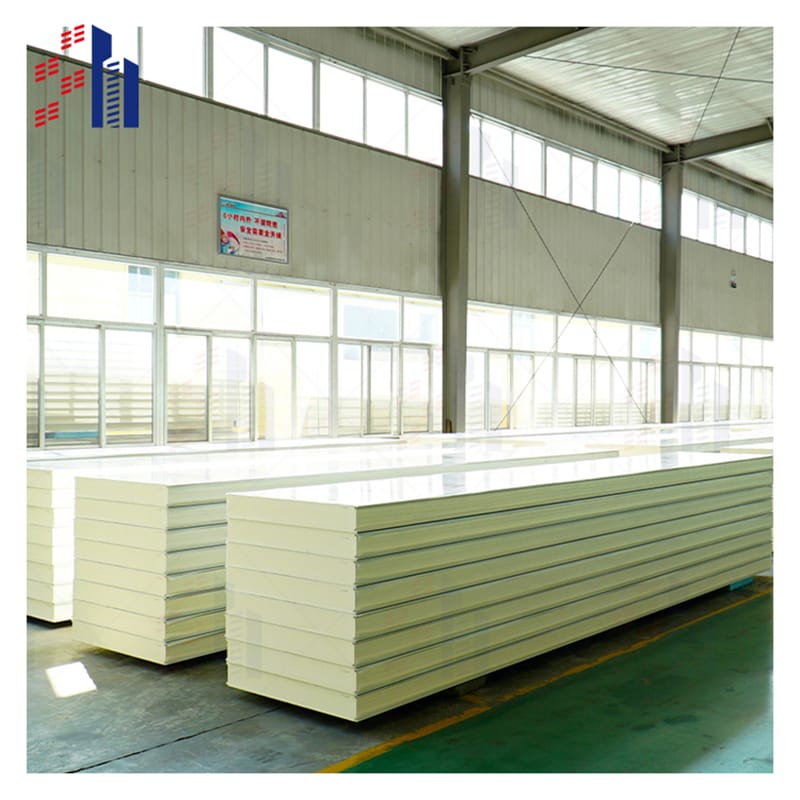

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Foamed Pcw |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Components of Plywood Foam Sandwich Panels

- Plywood Faces: Usually consisting of high-quality hardwood or softwood veneers, plywood skins are selected based on the panel’s application requirements. These facings guarantee surface toughness and resistance to impacts.

- Foam Core: Common foam materials include extruded polystyrene (XPS), polyurethane (PU), and polyvinyl chloride (PVC) foams. Each type offers different thermal insulation values, density, and moisture resistance. XPS foam core is prized for its consistent insulation and water resistance, PU foam offers superior thermal performance, and PVC foam adds chemical resistance.

- Optional Reinforcements: For specialized uses, extra layers like fiberglass mats, aluminum sheets, or resin coatings can be integrated to enhance moisture resistance, fire retardancy, or mechanical strength.

Comparison with Traditional Plywood and Other Composite Panels

Compared to traditional plywood, plywood foam sandwich panels surpass in thermal insulation, dimensional stability, and weight reduction. They prevent warping and swelling, common issues in plain plywood exposed to moisture. Unlike conventional SIPs typically used in wall assemblies, plywood foam sandwich panels offer a more versatile surface suitable for furniture, marine, and transportation purposes. Their foam core also provides improved acoustic insulation and better resistance against environmental factors than typical wood or fiber-based panels.

Manufacturing Process Overview

The production of plywood foam sandwich panels involves several critical steps:

- Preparation of plywood skins to precise thickness and grading.

- Cutting and shaping of the foam core to match panel dimensions.

- Adhesive application, typically using high-performance cold or hot-setting adhesives to ensure strong bonding.

- Lamination under controlled pressure and temperature, creating an integrated panel with flawless-to-core adhesion.

- Finishing touches, which may include trimming, sanding, or surface treatments to meet specific customer specifications.

This manufacturing process ensures that the plywood foam sandwich panels deliver consistent performance needed across industries demanding reliable, lightweight, and high-strength plywood panels.

Plywood foam sandwich panels offer a modern solution that combines the best materials available to deliver panels suitable for a wide range of construction, RV, marine, and industrial applications. If you’re exploring lightweight sandwich panels that don’t compromise on durability or insulation, these composite panels are worth considering.

Benefits of Plywood Foam Sandwich Panels

Plywood foam sandwich panels offer a range of advantages that make them an excellent choice for many building and manufacturing needs across the United States.

Lightweight Design and Strength

One of the biggest selling points is their lightweight construction. Thanks to a foam core paired with sturdy plywood skins, these panels deliver a high strength-to-weight ratio. This means you get the strength and durability you need without the heavy bulk of traditional materials. It’s especially useful in industries like RV manufacturing and modular homes where weight savings translate directly into better performance and fuel efficiency.

Superior Thermal Insulation

The foam core panels provide excellent thermal insulation, far surpassing standard plywood alone. This helps maintain consistent indoor temperatures, reduces energy bills, and enhances comfort in both residential and commercial buildings. Compared to other structural insulated panels (SIPs), plywood foam sandwich panels combine insulation with structural integrity, offering a two-in-one solution.

Moisture Resistance and Durability

Enhanced with fiberglass or aluminum facings, these panels resist moisture better than regular plywood. That means less risk of warping, swelling, or mold growth. This makes them ideal for use in demanding environments like marine applications, where moisture resistance is crucial.

Sustainability and Eco-friendly Materials

Many plywood foam sandwich panels now incorporate eco-friendly materials, including recycled plywood and bio-based foam cores. This focus on sustainability helps reduce environmental impact without sacrificing performance. Using these panels supports green building initiatives and can contribute to LEED certification points.

Versatility Across Industries

The versatility of plywood composite panels makes them suitable for a broad range of applications such as:

- Roofing, walls, and flooring in construction

- Lightweight, insulated panels in RVs and campers

- Marine interiors and partitions

- Furniture design where weight and structure matter

- Cargo solutions in transportation like trucks and trailers

This versatility combined with performance benefits puts plywood foam sandwich panels at the forefront for projects demanding lightweight, durable, and thermally efficient materials.

In short, these panels deliver a winning mix of lightweight strength, superior insulation, moisture resistance, and environmental responsibility — tailored to fit today’s diverse U.S. market needs.

Applications of Plywood Foam Sandwich Panels

Plywood foam sandwich panels offer versatile solutions across multiple industries, thanks to their lightweight structure, thermal insulation, and high strength-to-weight ratio. Here’s where they shine the most:

Construction Industry

These panels are a great fit for:

- Roofs, walls, and flooring in both residential and commercial buildings

- Modular homes where quick assembly and energy efficiency matter

- Interior insulation panels that reduce heating and cooling costs

The foam core provides superior insulation, making them an efficient choice for energy-conscious construction.

RV and Camper Manufacturing

In the RV and camper world, weight savings and insulation are critical Plywood foam sandwich panels:

- Deliver strong, lightweight interior panels that improve fuel efficiency

- Enhance thermal insulation, keeping interiors comfortable year-round

- Increase durability to withstand road vibrations and moisture

Case study: Shanghe’s panels have helped RV manufacturers improve insulation performance significantly while reducing overall vehicle weight, leading to better fuel economy and longer-lasting interiors.

Marine Applications

For boats and marine vessels, these panels are ideal for:

- Boat interiors and partitions where moisture resistance and weight reduction matter

- Lightweight, durable bulkheads and wall panels that stand up to harsh marine environments

Their enhanced moisture resistance, especially with optional fiberglass or aluminum facings, makes them suitable for marine use.

Furniture and Interior Design

Plywood foam sandwich panels also find use in:

- Lightweight furniture that is strong and easy to move

- Interiordecorative panels** that offer good aesthetics without sacrificing durability

- storage and display units where reducing weight is beneficial

Transportation Industry

For trucks, trailers, and cargo solutions, these panels provide:

- Lightweight cargo floorboards and wall panels to maximize payload

- Structural integrity to withstand transport stresses

- Thermal insulation to protect sensitive goods

By reducing vehicle weight, these panels help improve fuel efficiency and lower operating costs.

plywood foam sandwich panels from Shanghe deliver high performance across sectors—construction, marine, transportation, and more—thanks to their balanced mix of strength, weight savings, and insulation. This makes them a smart choice for U.S. customers looking for reliable, efficient building and manufacturing solutions.

Technical Specifications and Performance of Plywood Foam Sandwich Panels

When it comes to plywood foam sandwich panels, understanding the technical specifications is crucial for selecting the right product for your project. These panels combine plywood skins with a foam core, delivering impressive mechanical strength along with excellent insulation properties.

Mechanical Properties

- Flexural Rigidity: Our panels offer high flexural rigidity, meaning they resist bending under load. This makes them ideal for applications where strength and stiffness are critical, such as flooring and structural walls.

- Shear Modulus: The foam core contributes to shear strength, ensuring the panel maintains shape and structural integrity under stress. This boost in shear modulus makes plywood foam sandwich panels a reliable choice over traditional plywood or single-material panels.

Thermal and Acoustic Insulation Performance

- Thermal Insulation: The foam core—whether XPS, PU, or PVC foam—provides superior thermal resistance. Our panels deliver R-values typically ranging from 4 to 7 per inch, outperforming many traditional construction materials and helping reduce heating and cooling costs.

- Acoustic Insulation: Beyond thermal benefits, these panels also dampen sound transmission, making them excellent for residential interiors, RVs, and marine applications where noise control is important.

R-Value Comparisons

- Compared to conventional plywood or OSB panels, plywood foam sandwich panels offer substantially higher R-values thanks to their foam core.

- For example, a 1-inch plywood foam sandwich panel with XPS foam can provide nearly double the insulation of plywood alone.

Certifications and Standards

Our plywood foam sandwich panels meet or exceed key industry standards, including:

- ASTM International standards for structural integrity

- ANSI certifications for building materials

- Compliance with fire retardant regulations when custom treated

- Green certifications emphasizing the of eco-friendly core materials and sustainable manufacturing processes

Customization Options

We understand every project is unique. That’s why we offer flexible customization, including:

- Thickness ranges from 10 mm to 50 mm to suit load and insulation needs

- Core densities from 30 to 60 kg/m³, balancing weight and strength

- Diverse surface treatments like moisture-resistant plywood facings, fiberglass skins, or aluminum overlays for enhanced durability

- Optional reinforcements tailored for heavy-duty and marine environments

Comparison with Other Materials

| Feature | Plywood Foam Sandwich Panels | Traditional Plywood | Structural Insulated Panels (SIPs) |

|---|

| Weight | Lightweight | Heavier | Varies |

| Thermal Insulation | High (R-4 to R-7 per inch) | Low (R-1 per inch) | High |

| Moisture Resistance | Enhanced with coatings | Moderate | Moderate to high |

| Structural Strength | Excellent | Good | Excellent |

| Customization | Wide variety | Limited | Moderate |

Our plywood foam sandwich panels bring together strength, lightweight design, and superior insulation to meet varied project demands. Whether you’re building modular homes, marine interiors, or transportation solutions, these panels stand out for their balanced mechanical and thermal performance, backed by industry certifications and flexible customization.

Why Choose Shanghe’s Plywood Foam Sandwich Panels

When it comes to plywood foam sandwich panels, Shanghe stands out with a strong commitment to quality, innovation, and customer satisfaction. Here’s why choosing Shanghe makes a difference for your lightweight sandwich panel needs.

Advanced Technology for Strength and Lightweight Performance

Shanghe uses proprietary technology that boosts the panel’s structural integrity while keeping the weight low. This means you get high-strength plywood panels with enhanced durability, ideal for applications demanding both toughness and ease of installation. The unique bonding techniques and foam core integration ensure long-lasting performance without sacrificing weight.

Commitment to Sustainability and Eco-Friendly Materials

Sustainability is at the core of Shanghe’s manufacturing process. Their plywood foam sandwich panels leverage eco-friendly building materials, including responsibly sourced plywood and recyclable foam cores like XPS, PU, and PVC foam. This helps reduce environmental impact—important for US markets focused on green construction and energy efficiency.

Custom Solutions Tailored to Industry Needs

No two projects are the same. That’s why Shanghe offers custom panel solutions tailored to the exact requirements of different industries—from construction and marine to RV manufacturing and transportation. Whether you need enhanced thermal insulation, moisture resistance, or fire-retardant options, Shanghe can provide panels adapted to your specific application.

Rigorous Quality Control and Global Standards Compliance

Quality is never compromised. Shanghe follows strict quality control protocols throughout the manufacturing stages to ensure each plywood foam sandwich panel meets or exceeds industry standards. These panels come certified for mechanical strength, thermal performance, and moisture resistance, aligning with US and international norms for building materials.

Dedicated Customer Support and Technical Guidance

Shanghe supports customers beyond the purchase. Their team provides **technical guidance on selecting the right panel, installation tips, maintenance, and even-specific consulting. This hands-on support simplifies decision-making and enhances your success with plywood foam sandwich panels.

For detailed options on thickness, core types, and surface choices, explore Shanghe’s insulated sandwich panels or check out their wood sandwich panel range.

In : Shanghe combines industry-leading technology, eco-conscious materials, customizable options, strict quality control, and solid customer support to deliver some of the best plywood foam sandwich panels in the US market.

How to Select the Right Plywood Foam Sandwich Panel

Choosing the right plywood foam sandwich panel can make all the difference in your project’s performance, durability, and cost-effectiveness. Here’s what to consider to get the best fit for your needs.

Consider Your Application and Load Requirements

- Structural demands: Determine the weight and stress the panel will face. For floors or walls in heavy-duty construction, select panels with higher flexural rigidity and shear strength.

- Purpose: Whether it’s for insulation, aesthetics, or structural support, your choice of panel should reflect this. For example, panels used in modular homes or RVs should balance weight with durability.

- Environmental exposure: Outdoor applications or marine uses require panels resistant to moisture, UV, and temperature changes.

Evaluate Environmental Conditions

- Moisture and humidity: For wet or humid environments, panels with moisture-resistant skins (like fiberglass facing) and water-resistant foam cores are best.

- Temperature range: Extreme hot or cold conditions call for panels with higher thermal insulation values, such as those using XPS or PU foam cores.

- Fire resistance: Depending on code requirements, panels with fire-retardant treatments or specific core materials may be necessary.

Core Material Selection: XPS vs PU vs PVC Foam

- XPS (Extruded Polystyrene foam): Offers strong thermal insulation, moisture resistance, and good compressive strength. Ideal for roofing and wall sandwich panels.

- PU (Polyurethane foam): Known for superior insulation (higher R-value) and lighter weight. Common in transport applications and RV sandwich panels.

- PVC (Polyvinyl Chloride foam): Durable, impact-resistant, and excellent for marine or heavy-duty industrial uses, though slightly heavier than PU.

Skin Material Options: Plywood, Fiberglass, Aluminum

- Plywood facings: Provide excellent strength, natural appearance, and easy workability. Great for construction, furniture, and interior panels. Check thickness and wood grade based on load and finish requirements.

- Fiberglass skins: Lightweight and highly resistant to moisture and corrosion. Perfect for marine and RV panels, or areas needing high moisture protection.

- Aluminum facings: Offer superior durability, fire resistance, and lightweight. Ideal for high-performance exterior cladding or transport vehicle panels.

Tips for Installation and Maintenance

- Proper handling: Avoid bending or dropping panels, as foam cores can crush and weaken.

- Sealing edges and joints: Use appropriate sealants to prevent moisture ingress, especially in outdoor or marine settings.

- Fastening: Use recommended screws or adhesives compatible with both skin and core materials to ensure complete bonding.

- Routine inspection: Check for delamination or damage periodically, especially in high-moisture environments.

Consult Shanghe for Project-Specific Recommendations

Every project has unique needs. At Shanghe, our experts can help you:

- Match the right panel thickness, core density, and skin type to your application.

- Customize panels for special environmental or load conditions.

- Provide technical support for installation techniques and maintenance.

Explore our full range of plywood foam sandwich panels and tailored solutions at Shanghe’s wood sandwich panels.

Challenges and Considerations for Plywood Foam Sandwich Panels

While plywood foam sandwich panels offer many advantages, it’s important to be aware of some potential challenges and plan accordingly to get the best performance.

Potential Drawbacks

- Incomplete bonding issues: Poor adhesion between plywood facings and foam core can lead to panel delamination or reduced structural integrity. This usually happens if manufacturing controls aren’t tight or if panels are exposed to harsh conditions.

- Fire resistance concerns: Foam cores, especially polyurethane (PU) and PVC, are generally combustible. Without proper fire retardant treatments or protective facings like fiberglass or aluminum, the panels might not meet fire safety codes in all applications.

- Environmental exposure: Extended exposure to moisture or UV rays can degrade panel performance over time unless enhanced protective skins or coatings are used.

Mitigating Risks Through Design and Material Selection

To handle these issues effectively:

- Choose high-quality adhesives and ensure strict manufacturing quality control for strong bonding between plywood skins and foam core.

- Opt for fire-retardant foam cores or panels with secondary fire-resistant layers to meet local safety regulations.

- Use fiberglass or aluminum facings to improve moisture resistance and durability in outdoor or humid environments.

- Regularly inspect and maintain panels, especially in demanding conditions like marine or transportation applications.

Addressing Environmental Concerns and Lifecycle Management

Sustainability is a key priority in today’s building materials market, including for plywood foam sandwich panels:

- Many manufacturers, including Shanghe, prioritize using eco-friendly foam cores such as bio-based or recycled XPS, PU, or PVC foams.

- Some panels are designed to be fully recyclable, and efforts are in place to manage end-of-life disposal responsibly.

- Proper design can extend panel life and reduce waste, contributing to a lower environmental footprint over the product’s full lifecycle.

By understanding these challenges and carefully selecting plywood foam sandwich panels with the right core materials, facings, and proper installation, you can ensure optimal performance and longevity while supporting sustainable practices.

Future Trends in Plywood Foam Sandwich Panels

Plywood foam sandwich panels are evolving fast, driven by demand for lighter, stronger, and greener building materials across the U.S. market. Here’s what’s shaping the future of these versatile panels:

Advances in Eco-Friendly Core Materials

The industry is moving toward using bio-based foams and other sustainable core materials that reduce environmental impact without sacrificing performance. These eco-friendly foams offer:

- Lower carbon footprints compared to traditional polyurethane (PU) or XPS foams

- Improved biodegradability and easier recycling options

- Better compliance with green building standards and certifications

Integration with Smart Building Technologies

Plywood foam sandwich panels are starting to play a bigger role in smart buildings. For example:

- Panels embedded with sensors for real-time monitoring of temperature, humidity, or structural health

- Integration with IoT systems to optimize energy efficiency and maintenance

- Use in energy-efficient prefabricated homes and commercial builds

Growing Demand in Sustainable Construction and Lightweight Vehicles

There’s a rising trend toward sustainability and weight reduction in construction and transportation sectors, which drives plywood foam sandwich panel innovation:

- Increased use in modular homes and green building projects aiming for rapid assembly and energy savings

- Expanded adoption in RVs, campers, and lightweight trailers, where durability and insulation matter

- Applications in lightweight cargo solutions for trucks and trailers to boost fuel efficiency

Shanghe’s Innovation Roadmap for Composite Panels

At Shanghe, we’re committed to staying ahead with focused innovation on:

- Developing improved plywood composite panels with enhanced strength-to-weight ratios

- Introducing new foam cores, including bio-based and fire-retardant options

- Offering customized solutions tailored for diverse industries such as marine, transport, and construction

- Ensuring our products meet or exceed global quality and environmental standards

For more on our expanded product range and materials technology, check out our polyurethane foam sandwich panels and fireproof sandwich panels—both designed for next-gen performance.

By adopting these trends, plywood foam sandwich panels will continue to be a top choice for industries that need lightweight, durable, and sustainable materials that meet today’s and tomorrow’s challenges.

FAQs About Plywood Foam Sandwich Panels

What Are the Main Advantages of Plywood Foam Sandwich Panels

Plywood foam sandwich panels offer a lightweight yet strong structure, thanks to their foam core paired with plywood facings. This design delivers:

- Superior thermal insulation compared to traditional plywood, helping reduce energy costs.

- An excellent strength-to-weight ratio, making them ideal for applications where every pound counts.

- Moisture resistance, especially when enhanced with fiberglass or aluminum layers, providing durability in damp or humid environments.

- Versatility in use, from construction and marine to vehicle manufacturing.

- Environmentally friendly options with eco-conscious core materials, supporting sustainable building efforts.

How Do These Panels Compare to Traditional Structural Insulated Panels (SIPs)

While both plywood foam sandwich panels and traditional SIPs provide insulation and strength, plywood foam panels stand out with:

- Better flexibility in skin material options (plywood, fiberglass, aluminum), catering to different project needs.

- A lighter weight, which makes handling and installation easier without compromising strength.

- Enhanced moisture resistance when paired with proper facings, whereas traditional SIPs might absorb moisture more readily.

- Customization in foam core types like XPS, PU, or PVC foam for tailored thermal and mechanical properties.

Are Plywood Foam Sandwich Panels Suitable for Marine Environments

Yes, absolutely. These panels are widely used in marine composite applications, including boat interiors and partitions, because:

- The foam core combined with plywood skins, especially when reinforced with fiberglass or coated with waterproof materials, offers excellent moisture resistance.

- Their lightweight nature helps improve fuel efficiency and maneuverability.

- The panels resist corrosion and mildew better than many traditional materials used in marine settings.

What Customization Options Are Available

Shanghe’s plywood foam sandwich panels can be customized to meet specific project needs, including:

- Core material choice: XPS foam, polyurethane (PU), or PVC foam based on insulation and rigidity requirements.

- Thickness and density: Different panel thicknesses and foam densities to balance performance and weight.

- Surface treatments: Options like fiberglass or aluminum facings for enhanced durability and moisture resistance.

- Sizes and shapes: Cut to fit particular dimensions or design needs in construction, marine, or transportation sectors.

What Are the Best Practices for Installation

To maximize the lifespan and efficiency of plywood foam sandwich panels, keep these tips in mind:

- Ensure proper bonding during installation to avoid delamination issues.

- Use panels designed with moisture-resistant facings in humid or outdoor environments.

- Follow manufacturer recommendations on load limits and handling to maintain panel integrity.

- Consult Shanghe’s technical support for project-specific guidance on installation and maintenance.

By understanding these FAQs, you’ll be better equipped to choose, customize, and install plywood foam sandwich panels that fit your project and performance goals perfectly.