What Are Polyurethane Foam Sandwich Panels

Polyurethane foam sandwich panels are advanced thermal insulation panels that feature a core of high-density polyurethane (PU) foam securely sandwiched between two outer skins made from materials like metal (steel or aluminum), fiberglass, or composite materials. This construction creates a lightweight yet incredibly strong panel, perfect for a variety of building and industrial applications.

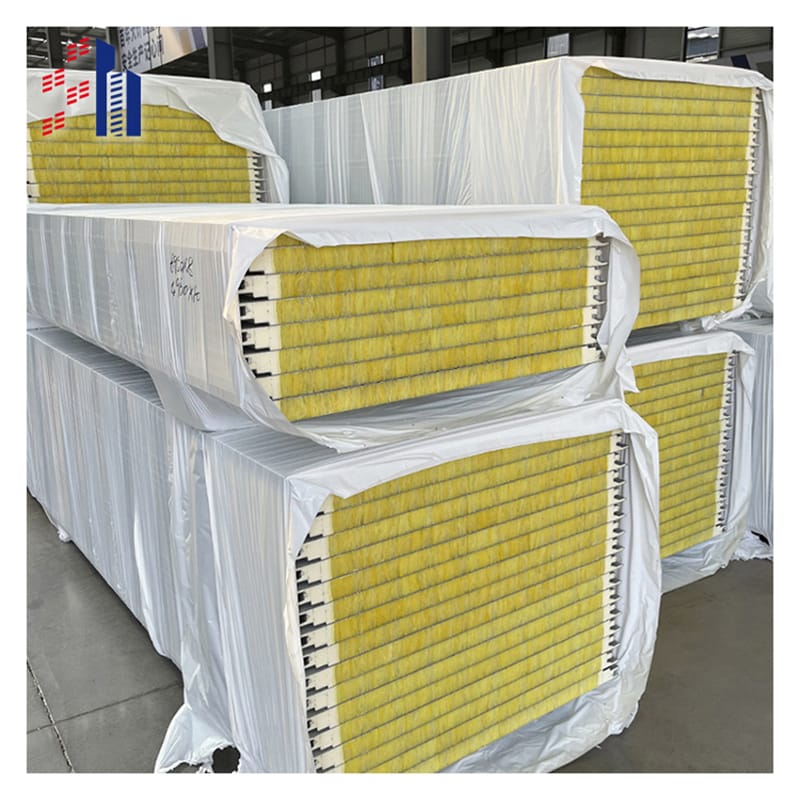

Customers visit the factory

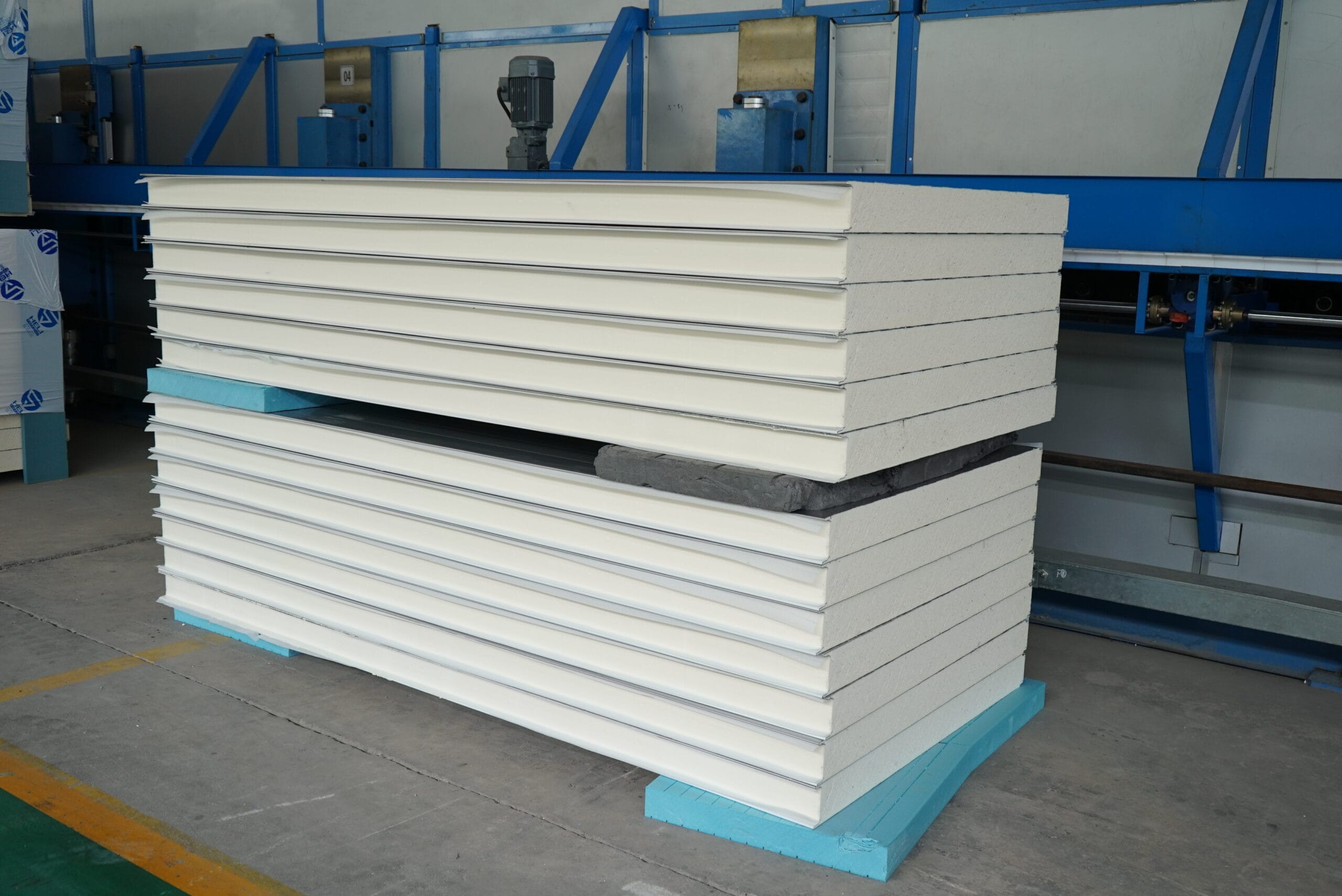

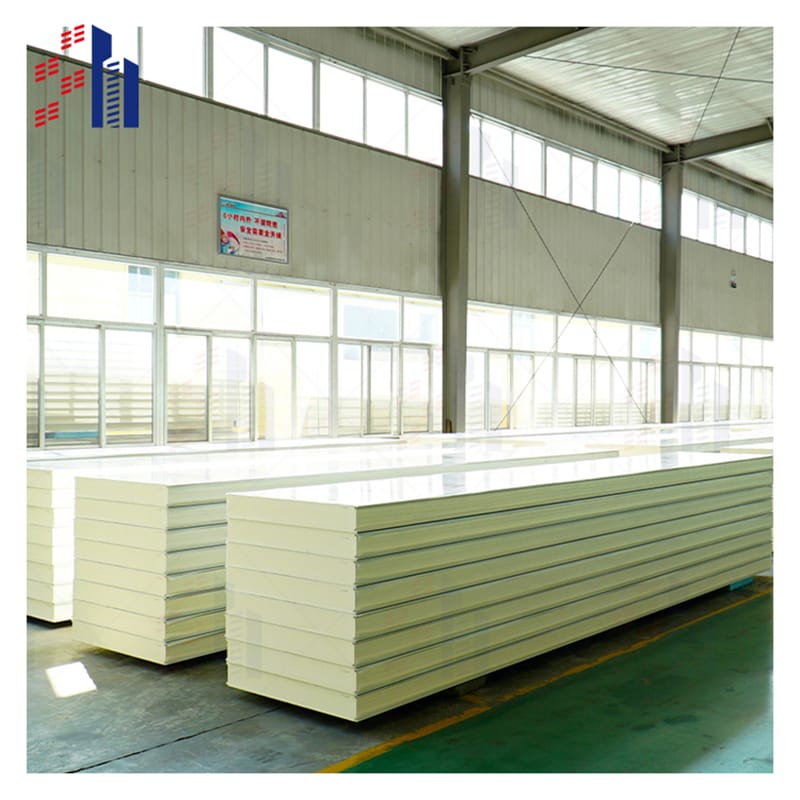

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Foamed Pcw |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Structure and Composition

The key to these panels lies in their three-layered structure:

- Core: Rigid PU foam provides superior insulation with low thermal conductivity typically ranging between 0.022 to 0.033 W/m·K. This core ensures excellent energy efficiency by minimizing heat transfer.

- Outer Skins: These durable layers protect the foam core and provide structural strength. Choices include galvanized steel, aluminum sheets, or fiberglass skins, depending on specific performance and aesthetic requirements.

Key Properties

- Lightweight: PU foam sandwich panels weigh significantly less than traditional materials, reducing transportation and handling costs.

- High Thermal Insulation: Their low thermal conductivity makes them ideal for cold storage, residential, and commercial insulation needs.

- Durability and Weather Resistance: The robust outer skins resist moisture, UV rays, and chemical exposure, ensuring long-term performance.

- Fire Resistance: Especially with PIR foam cores, these panels offer enhanced fire safety properties compared to standard PUR foams.

Comparison With Other Materials

Compared to conventional insulation panels:

| Material | Thermal Conductivity (W/m·K) | Weight | Fire Resistance | Use Case |

|---|

| Polyurethane Foam | 0.022 – 0.033 | Lightweight | Moderate to High (PIR) | Energy-efficient walls, roofs |

| Polystyrene (EPS/XPS) | 0.030 – 0.040 | Lightweight | Lower fire resistance | Budget projects, basic insulation |

| Mineral Wool | 0.035 – 0.045 | Heavier | High fire resistance | Fire-rated applications |

PU foam sandwich panels strike the best balance between weight, thermal efficiency, and fire safety—outperforming mineral wool in insulation but offering better fire performance and weight advantage over polystyrene.

Shanghe’s polyurethane insulated panels leverage this structure and material quality, meeting the demands of the U.S. market for lightweight, durable, and energy-efficient building solutions.

Benefits of Shanghe Polyurethane Foam Sandwich Panels

Choosing Shanghe polyurethane foam sandwich panels means investing in top-notch performance for your building projects. Here’s why these PU sandwich panels stand out in the U.S. market:

Superior Thermal Insulation

Our panels feature a low thermal conductivity ranging from 0.022 to 0.033 W/m·K, ensuring excellent thermal insulation. This keeps your buildings energy-efficient by reducing heating and cooling costs, making them ideal for tight energy codes and sustainable construction.

Lightweight and Durable

Designed for quick and easy installation, these panels are lightweight yet strong, offering long-term structural stability. They reduce labor costs and speed up construction while maintaining resistance to wear, weather, and mechanical stress.

Versatility Across Applications

Whether you’re working on residential homes, commercial spaces, industrial facilities, or cold storage warehouses, Shanghe PU foam sandwich panels adapt seamlessly. Their durability and insulation performance make them perfect for walls, roofs, floors, and modular building systems.

Eco-Friendly Options

Shanghe is committed to sustainability. We use PIR (polyisocyanurate) foam options that provide enhanced thermal performance with a greener footprint. Our panels also incorporate recyclable components, aligning with eco-conscious building practices popular in the U.S. market.

Enhanced Fire Resistance

Compared to standard PUR foam, PIR foam panels offer superior fire resistance, meeting stricter safety standards. This is critical for commercial and industrial applications where fire safety codes are stringent, giving you peace of mind without sacrificing insulation quality.

By selecting Shanghe polyurethane foam sandwich panels, you benefit from energy-efficient, lightweight, versatile, eco-friendly, and fire-resistant solutions designed to meet today’s U.S. construction demands.

Applications of Polyurethane Foam Sandwich Panels

Polyurethane foam sandwich panels are versatile building materials widely used across various industries thanks to their excellent thermal insulation, durability, and lightweight nature. Here’s where they really shine:

Construction Industry

These panels are ideal for walls, roofs, and floors in residential, commercial, and industrial buildings. Their strong insulation properties help maintain energy efficiency, reducing heating and cooling costs. Plus, their lightweight build makes installation faster and easier without compromising structural stability.

Cold Storage and Refrigeration

PU sandwich panels are a go-to choice for cold storage facilities, including refrigerated warehouses and transport containers. The panels provide consistent, high-performance insulation to maintain low temperatures, reduce energy consumption, and improve product shelf life.

Modular and Portable Buildings

Because of their ease of handling and installation, these panels are perfect for prefabricated homes, portable cabins, temporary shelters, and other modular builds. They speed up construction times and offer durable, lightweight solutions that can be relocated as needed.

Specialized Use Cases

Polyurethane foam sandwich panels also serve well in niche applications like:

- Clean rooms requiring contamination control and strict temperature regulation

- Sports facilities that benefit from thermal comfort and sound insulation

- Agricultural buildings such as barns and storage sheds where moisture resistance and temperature control are essential

Thanks to their high thermal insulation value and weather resistance, these panels are trusted across a wide range of settings, helping save on energy while providing reliable structural support. Whether it’s a new construction project or retrofit application, PU sandwich panels offer a flexible, effective solution tailored to diverse needs.

Global Strength, Local Grit: Why We’re Your Go-To Polyurethane Foam Sandwich Panels Supplier

From Saudi warehouses to Canadian farms, we’ve shipped 5M+ sqm. As a top polyurethane foam sandwich panels supplier, we handle headaches you didn’t know existed:

Logistics? FOB/CIF/DDP—your call. We ship from Guangzhou port in 10 days flat.

Support? On-site install teams or video calls—24/7.

Warranty? 5-year coverage. Sleep easy.

Real talk: If your current supplier ghosts you post-sale, you’re screwed. We don’t do that.

Customization to Fit Your Project Needs

No two projects are the same, so we offer a wide range of options:

- Multiple panel sizes and thicknesses to match construction requirements

- Various skin materials like steel, aluminum, and fiberglass for different aesthetics and durability

- Options tailored for residential, industrial, or specialized uses

This flexibility makes Shanghe’s polyurethane insulated panels a go-to choice for builders and contractors across the U.S.

Commitment to Sustainability and Eco-Friendly Production

Shanghe takes environmental responsibility seriously:

- Use of eco-friendly raw materials including recyclable PIR foam components

- Energy-efficient manufacturing processes that reduce emissions and waste

- Panels designed to contribute to building energy savings over their lifecycle

Choosing Shanghe means supporting greener building practices without compromising performance.

Global Reach with Reliable Supply Chain

We know timing matters. That’s why Shanghe maintains:

- A strong, reliable supply chain for prompt delivery across the U.S. and international markets

- Consistent product availability, helping you avoid delays on your projects

- Responsive customer support for quotes, consultations, and orders

Contact Shanghe for Your Polyurethane Foam Sandwich Panel Needs

For superior thermal insulation panels backed by quality, customization, and sustainability, talk to Shanghe today.

- Get a personalized quote or consultation

- Learn how our panels can save you energy and installation time

- Experience the difference a trusted manufacturer brings

Reach out now and ensure your next project uses some of the best polyurethane foam sandwich panels available in the U.S. market.

How Polyurethane Foam Sandwich Panels For Sale Make Your Crew Rockstars

Contractors, this one’s for you. Tired of crews moving like snails? Our polyurethane foam sandwich panels for sale install faster than TikTok trends. Camlock joints snap together like Legos—no specialty tools needed. One crew in Ohio built a 10,000sq ft cold storage in 3 days (normally 5!). Bonus: Panels weigh 70kg max, so no cranes. Result? Finish early, collect checks faster, and bid the next job

Technical Specifications of Polyurethane Foam Sandwich Panels

Density and Strength

Shanghe’s polyurethane foam sandwich panels feature a core density typically ranging from 28 to 50 kg/m³, striking the perfect balance between lightweight design and structural strength. This density ensures the panels offer outstanding strength-to-weight ratio, making them ideal for quick installation while maintaining long-term durability.

Thermal Conductivity Performance

One of the key benefits is the low thermal conductivity of PU foam cores, usually between 0.022 to 0.033 W/m·K. This means our panels outperform common insulation materials like EPS (expanded polystyrene) and XPS (extruded polystyrene), delivering superior thermal insulation that helps reduce energy costs for heating and cooling in residential, commercial, and industrial buildings.

Mechanical Properties

Our panels are engineered to resist mechanical stresses, offering:

- High compressive strength to support heavy loads without deformation

- Good flexural rigidity to maintain panel shape under bending forces

- Excellent shear resistance to ensure joint stability and prevent panel separation

These properties make Shanghe’s PU insulated panels reliable for walls, roofs, floors, and specialized applications requiring structural integrity.

Industry Standards Compliance

Shanghe’s PU sandwich panels meet and often exceed recognized standards like EN 14509, which governs factory-made sandwich panels for buildings. Compliance with these standards ensures consistent product quality, fire performance, and durability, giving you confidence in both safety and longevity for your building projects.

This technical profile makes Shanghe’s polyurethane foam sandwich panels a top choice for anyone looking for energy-efficient panels that don’t compromise on strength or safety. If you are comparing insulation options, these specs clearly highlight why PU foam panels perform better in many real-world applications.

Installation and Maintenance Tips for Polyurethane Foam Sandwich Panels

Installing Shanghe polyurethane foam sandwich panels is straightforward, designed to save time and reduce labor costs while ensuring a strong, weather-tight build. Here’s a clear, step-by-step guide to help you get the job done right.

Installation Steps for Shanghe PU Sandwich Panels

- Panel Orientation: Panels can be installed horizontally or vertically depending on your project needs. Choose the orientation that suits walls, roofs, or floors.

- Linking Panels: Use the built-in tongue-and-groove or shiplap joints for tight, secure connections between panels. This seals gaps and improves insulation efficiency.

- Sealing and Waterproofing: Apply appropriate sealants or foams at joints and edges. This step prevents moisture penetration and improves weather resistance.

- Fastening: Secure panels using recommended self-tapping screws or fasteners compatible with the chosen skin material (steel, aluminum, fiberglass). Fasten at proper intervals for structural stability.

- Handling Panels: Panels are lightweight but handle with care to avoid dents or damage to the skins and core.

Your Blueprint for Wholesale Polyurethane Foam Sandwich Panels

Wanna boost margins by 30%? Listen up. Buying wholesale polyurethane foam sandwich panels straight from the factory is like finding a gold mine. Our MOQ starts at 500m², with prices diving to $7.76/sqm at volume. Custom specs? No sweat. Need 150mm thickness for a freezer warehouse? Or 50mm for a retail store? Done. We’ll even throw in RAL-color matching so architects get their Pantone-perfect facade. Pro tip: Skip the distributor. Go factory-direct. Keep cash in your pocke

Maintenance of Polyurethane Foam Sandwich Panels

To extend the life and performance of your polyurethane insulated panels, regular upkeep is simple but important:

- Cleaning: Wipe panels with mild detergent and water to remove dirt, dust, and pollutants. Avoid harsh chemicals that could degrade the surface.

- Inspecting for Damage: Check periodically for dents, cracks, or sealant failures. Promptly address any damage to prevent moisture intrusion or loss of insulation.

- Checking Seals and Fasteners: Ensure that all seals remain intact and fasteners are tight. Replace any worn sealant or loose screws.

Benefits of Proper Installation and Maintenance

- Ease of Installation reduces labor time and costs.

- Proper Sealing enhances thermal insulation and energy efficiency.

- Regular Maintenance guarantees longevity and sustained performance in various climates and applications.

With Shanghe PU sandwich panels, you get a product engineered for quick setup and low upkeep, ideal for residential, commercial, or industrial projects across the United States.

Comparing Polyurethane Foam Sandwich Panels to Alternatives

When choosing insulation and construction panels, it’s important to weigh the strengths and weaknesses of different materials. Here’s how polyurethane foam sandwich panels stack up against popular alternatives like polystyrene and mineral wool.

Polystyrene EPS and XPS Panels

- Lower upfront cost: EPS (expanded polystyrene) and XPS (extruded polystyrene) panels are generally cheaper than polyurethane foam sandwich panels.

- Weaker fire resistance: Both EPS and XPS have lower fire performance, which can limit their use in building codes requiring higher fire safety standards.

- Less effective insulation: Polystyrene panels have higher thermal conductivity (around 0.030-0.040 W/m·K), meaning they don’t insulate as well as PU foam panels. This can lead to higher energy costs over time.

- Durability concerns: Polystyrene can be more prone to moisture absorption and physical damage compared to polyurethane foam cores.

Mineral Wool Panels

- Excellent fire resistance: Mineral wool offers superior fire protection, often used where fire safety is critical.

- Heavier weight: Mineral wool panels are significantly heavier. This makes installation slower and adds extra load to structures.

- Lower thermal efficiency: Though fire-resistant, mineral wool isn’t as thermally efficient as polyurethane foam, with thermal conductivity typically ranging from 0.035 to 0.045 W/m·K.

- Less moisture resistant: Mineral wool can absorb water unless properly protected, which compromises insulation performance.

Shanghe Polyurethane Foam Sandwich Panels Edge

- Best balance of cost and performance: PU foam panels offer superior thermal insulation with low thermal conductivity (0.022-0.033 W/m·K), helping reduce energy bills.

- Lightweight and strong: Their low density means easier, faster installation and less structural support required without sacrificing durability.

- Fire-resistant PIR options: Shanghe supplies polyurethane foam sandwich panels with PIR cores, offering improved fire performance over standard PUR foam.

- Long-term sustainability: Made with eco-friendly materials and recyclable components, they provide a greener building choice.

- Versatile applications: Ideal for residential, commercial, industrial, and cold storage buildings thanks to their balance of insulation, strength, and fire safety.

Choosing Shanghe polyurethane foam sandwich panels gives you a product that outperforms polystyrene in insulation and fire safety, and improves on mineral wool when it comes to weight and thermal efficiency—making it the smart, energy-efficient, and sustainable choice for your next project.

Addressing Common Concerns of Polyurethane Foam Sandwich Panels

Cost and Long-Term Savings

When considering polyurethane foam sandwich panels, upfront costs can seem higher compared to some traditional materials like polystyrene or mineral wool. However, Shanghe offers competitive pricing that reflects the premium quality and performance of our panels. More importantly, the energy efficiency of PU insulated panels leads to significant savings over time by reducing heating and cooling expenses. The superior thermal insulation, with low thermal conductivity (0.022–0.033 W/m·K), means less energy is wasted, lowering your building’s operating costs and providing a quicker return on investment.

Fire Safety Advances in PIR Foam Panels

Fire resistance is a major advantage when choosing polyurethane foam sandwich panels, especially those with PIR (polyisocyanurate) foam cores. Compared to standard PUR foam, PIR foam offers enhanced fire performance, improving safety in residential, commercial, and industrial settings. Shanghe’s PU panels meet stringent fire safety regulations and industry standards, making them a trustworthy choice. This means you get panels that not only insulate but also provide better protection against fire hazards without sacrificing thermal performance.

Environmental Impact and Sustainability

Shanghe takes pride in its eco-conscious approach to manufacturing polyurethane foam sandwich panels. We focus on using recyclable components and sustainable raw materials, including options for PIR foam, which are designed to reduce environmental footprint. Our production processes aim to minimize waste and energy use, aligning with green building goals and regulations that are important in the U.S. market. Choosing Shanghe’s panels means supporting a greener future while enjoying lightweight, durable, and energy-efficient building materials.

By addressing cost, safety, and environmental concerns upfront, Shanghe makes it easier for customers in the United States to choose quality polyurethane foam sandwich panels that deliver long-term value and peace of mind.