Our Polyurethane Sandwich Panels are high-performance insulated building materials engineered for superior thermal efficiency, structural strength, and long-term durability. As a leading polyurethane sandwich panel China exporter, Shanghe delivers precision-manufactured panels suitable for demanding industrial, commercial, and residential applications.

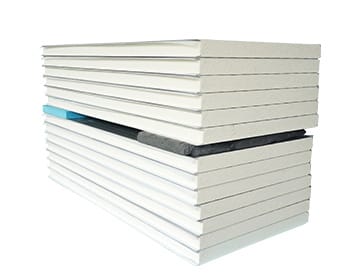

Each panel consists of a rigid high-density polyurethane (PU) foam core bonded between two durable facing sheets—typically galvanized steel, pre-painted steel, or aluminum—forming a lightweight yet strong composite system. The continuous production process ensures consistent quality, dimensional accuracy, and optimal insulation values.

Customers visit the factory

Installation details

Introduction to Polyurethane Sandwich Panels

Polyurethane Sandwich Panels (PU Panels) are advanced insulation components designed to meet stringent energy-saving and structural requirements. PU foam’s low thermal conductivity (≈0.018–0.024 W/m·K) makes these panels ideal for environments where temperature control is critical.

Key technical characteristics:

| Feature | Specification |

|---|

| Core Material | High-Density Polyurethane Foam |

| Facing Options | Pre-painted steel, galvanized steel, aluminum |

| Thickness Range | 30 mm – 150 mm |

| Panel Width | Common widths: 950 mm, 1000 mm, customizable |

| Thermal Conductivity | 0.018–0.024 W/m·K |

| Density | 38–42 kg/m³ (core) |

| Fire Rating | Optional Class B to Class A2 (custom fire-resistant formulas) |

Why Choose Polyurethane Sandwich Panels

When compared to EPS, rock wool, or traditional wall materials, PU sandwich panels offer unmatched performance-to-weight ratio:

- Excellent Thermal Insulation – Maintains stable indoor temperatures, reduces HVAC energy costs.

- Lightweight yet Strong – Easy handling and installation without sacrificing structural integrity.

- Long Service Life – PU foam core resists aging, shrinkage, and deformation over time.

- Moisture and Corrosion Resistance – Closed-cell foam prevents water ingress, while facing sheets protect against rust.

- Cost Efficiency – Reduced labor costs due to quick installation and minimal maintenance needs.

For buyers seeking polyurethane insulated panels from a trusted manufacturer, Shanghe offers a proven, export-ready product that meets global ISO, CE, and SGS quality standards.

About Shanghe Your Trusted China Exporter

Company Profile and Export Experience

Shanghe is a leading polyurethane sandwich panel manufacturer and exporter in China, supplying high-quality PU insulated panels to customers worldwide, including the United States. With over 15 years of manufacturing and export experience, we offer tailored solutions for cold storage, construction, and industrial projects. Our panels are produced in our state-of-the-art facility using advanced continuous production lines, ensuring consistent quality and competitive lead times. We understand U.S. buyers’ requirements—precise specifications, reliable delivery, and compliance with industry codes.

Certifications and Quality Standards

We comply with international and U.S.-preferred standards for safety, performance, and environmental requirements. Every batch is tested before shipment.

Certifications include:

- ISO 9001 – Quality Management System

- CE Marking – Conformity with European standards, widely accepted in U.S. projects

- SGS Test Reports – Independent third-party inspection and material verification

- FM Approved and ASTM-compliant options available upon request

These certifications ensure our PU sandwich panels meet strict thermal insulation, fire resistance, and durability requirements.

Export Capabilities and Global Shipping Solutions

Shanghe ships to North America, Europe, the Middle East, and Asia, with dedicated export teams handling customs clearance and full documentation. For U.S. clients, we arrange:

- FOB, CIF, and EXW terms to major ports including Los Angeles, Houston, and New York

- Sea freight, air freight, and rail options depending on urgency

- Customized packing methods to withstand long-distance shipping and avoid panel damage

- Inspection certificates and all required export paperwork for smooth import clearance

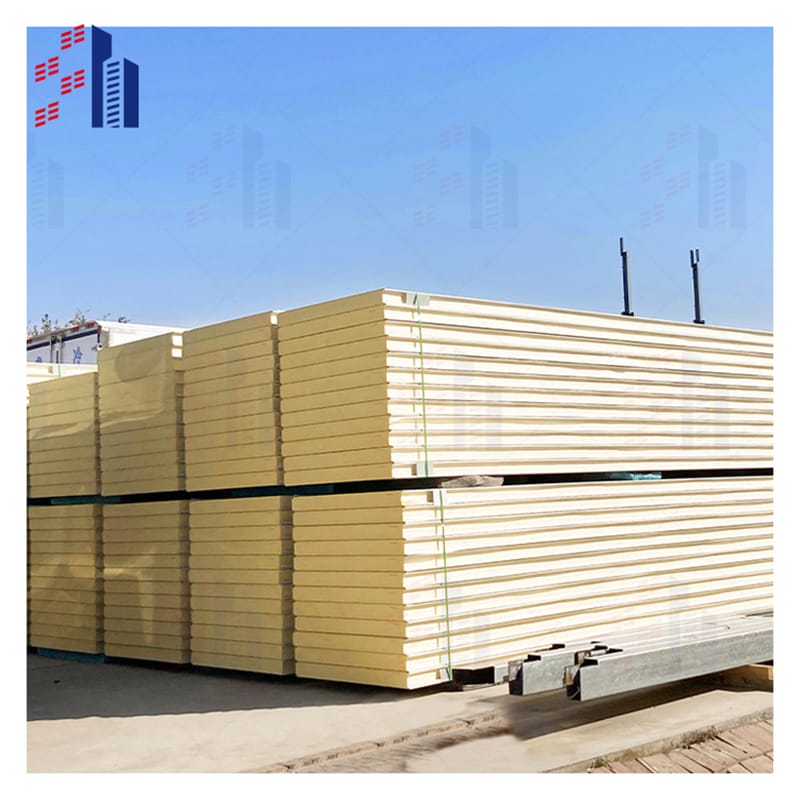

Factory and Production Capacity

Our factory covers over 20,000 m² with 3 advanced continuous production lines capable of producing up to 2 million m² of polyurethane sandwich panels annually. We use precision-controlled PU foaming technology to ensure uniform density and optimal insulation.

Key production strengths:

- Ability to manufacture custom lengths, widths, and thicknesses (30mm–150mm)

- Flexible steel and aluminum facing options to match project needs

- Strict QC checks at every stage, including adhesion, dimensional accuracy, and thermal performance tests

- High-volume order handling with stable supply for large construction projects

Shanghe delivers reliable, cost-effective, and U.S.-market-ready polyurethane sandwich panels backed by a proven export track record.

Technical Specifications of Polyurethane Sandwich Panel

Panel Core Material

Our polyurethane sandwich panels feature a high-density rigid PU foam core.

- Density: 38–45 kg/m³

- Closed-cell structure reduces heat transfer and moisture absorption.

- Proven thermal insulation performance with long-lasting stability.

Facing Materials

We offer multiple facing options to suit your project needs:

- Galvanized steel (zinc-coated for corrosion protection)

- Pre-painted steel (color-coated for enhanced durability and design)

- Aluminum sheet (lightweight and corrosion-resistant)

Thickness Range

Available panel thicknesses: 30mm, 50mm, 75mm, 100mm, 125mm, 150mm.

- Thin panels for partitions and light structures.

- Thicker panels for extreme temperature control in cold storage applications.

Sizes and Customization

- Standard width: 1000mm ± 5mm

- Length: Up to 12m (custom lengths on request)

- Custom profiles, colors, and coatings available for different architectural styles.

| Specification | Standard Range | Custom Option Available |

|---|

| Core Material | PU Foam | Yes |

| Facing | Steel/Aluminum | Yes |

| Thickness | 30–150 mm | Yes |

| Width | 1000 mm | No |

| Length | ≤ 12 m | Yes |

| Density | 38–45 kg/m³ | No |

Thermal Conductivity and Performance

- Thermal conductivity: ≤ 0.018–0.022 W/m·K

- Maintains stable insulation across hot and cold climates.

- Designed to meet ASHRAE recommendations for building energy efficiency in the United States.

Fire Resistance and Safety Classifications

- Fire rating: B1 (flame-retardant) or B2 (custom), meeting EN 13501-1 and GB 8624 standards.

- Non-toxic gas release in fire conditions, compliant with modern safety codes.

- Optional fireproof facing for facilities with stricter fire safety requirements.

These specifications make our polyurethane insulated panels ideal for cold storage warehouses, clean rooms, and industrial structures where energy efficiency, durability, and consistent quality are a must.

Product Features and Advantages of Polyurethane Sandwich Panels

Our polyurethane sandwich panels are engineered for performance, durability, and cost efficiency—making them a go-to choice for U.S. builders, contractors, and cold storage operators. Here’s what makes them stand out:

Superior Thermal Insulation and Energy Efficiency

- High-density PU foam core delivers low thermal conductivity (~0.018–0.024 W/m·K).

- Helps reduce heating and cooling costs in all climates.

- Consistent insulation performance over the panel’s lifespan.

- Ideal for meeting U.S. building energy codes.

Lightweight with High Strength

- Up to 40% lighter than traditional building materials.

- Galvanized or pre-painted steel facings give excellent structural integrity.

- Easier transportation and installation without heavy machinery.

Moisture and Corrosion Resistance

- Closed-cell PU core prevents water absorption.

- Outer facings resist rust, mold, and mildew—even in humid warehouse or coastal environments.

- Perfect for cold storage, food facilities, and outdoor structures.

Easy Installation and Low Maintenance

- Panels come in ready-to-install modular sizes.

- Quick tongue-and-groove or concealed fastener systems save on labor costs.

- Minimal upkeep—just occasional cleaning is enough.

Long Service Life

- Designed to last 20–30+ years with minimal performance loss.

- Durable protective coatings prevent fading and surface damage.

- Withstands heavy use in industrial and commercial environments.

Eco-friendly and Non-toxic Materials

- CFC and HCFC-free PU foam—environmentally responsible formulation.

- Panels are fully compliant with RoHS and REACH standards.

- Helps projects meet LEED and green building certifications in the U.S.

Quick Spec Snapshot

| Feature | Specification / Benefit |

|---|

| Core material | High-density rigid PU foam |

| Thermal conductivity | 0.018–0.024 W/m·K |

| Thickness range | 30 mm – 150 mm |

| Facing options | Galvanized steel, pre-painted steel, aluminum |

| Expected lifespan | 20–30+ years |

| Environmental safety | CFC/HCFC-free, non-toxic |

Applications and Industry Use Cases for Polyurethane Sandwich Panels

Polyurethane (PU) sandwich panels are widely used across multiple industries in the United States because they combine high thermal insulation, lightweight design, and durability in one product. As a polyurethane sandwich panel China exporter, we manufacture and supply panels that meet the performance demands of different environments — from extreme cold storage to modern modular housing.

Cold Storage and Refrigerated Warehouses

PU sandwich panels are a top choice for temperature-controlled facilities.

- Maintain consistent low temperatures

- Prevent cold air loss for energy savings

- Moisture-resistant to stop condensation damage

- Meets hygiene standards for food and pharmaceutical storage

Common uses include walk-in freezers, refrigerated distribution centers, and food processing plants.

Clean Rooms and Laboratories

For industries where air purity and temperature control are critical, such as electronics, biotech, and pharmaceuticals:

- Smooth, non-porous surfaces for easy cleaning and sanitizing

- Resistant to bacterial and fungal growth

- Custom panel sizes to fit specialized layouts

- Compatible with HEPA filtration systems

Industrial and Commercial Buildings

PU insulated panels are ideal for factories, warehouses, and office complexes:

- Lightweight yet structurally strong for quick installation

- Excellent insulation for energy-efficient climate control

- Fire-rated options for enhanced safety compliance

- Acoustic control to reduce noise levels in busy workspaces

Residential Construction

Homebuilders and developers use PU sandwich panels for residential applications:

- Wall and roofing panels for energy-efficient houses

- Ideal for garage insulation, extension builds, or tiny homes

- Reduces heating and cooling costs year-round

- Aesthetic exterior finishes available to match home designs

Modular Buildings and Portable Cabins

For temporary or relocatable structures, polyurethane panels ensure durability without compromising portability:

- Prefabricated modular classrooms, offices, and worker housing

- Quick setup and dismantling without heavy equipment

- Built to withstand repeated transport and varying climates

- Customizable thickness and surface finishes

Our PU foam sandwich panels are engineered for versatility, serving industries from logistics and healthcare to residential and commercial construction — delivering performance, efficiency, and long-term value in every application.

Packaging Delivery and Export Terms for Polyurethane Sandwich Panels

Packaging Details for Safe Shipping

We make sure polyurethane sandwich panels arrive in excellent condition, even after long-distance shipping. Each panel is:

- Wrapped with protective film to guard against scratches and dirt

- Stacked on strong wooden pallets for stability

- Secured with steel or plastic strapping to prevent movement during transit

- Covered with waterproof wrapping to protect against moisture during sea or land transport

Custom packing is available for special requirements, ensuring safety for both domestic and international shipping.

Bulk Order Capabilities

Our production line supports large-scale orders without delay. We can:

- Produce and ship container loads of panels in consistent quality

- Handle mixed panel sizes and specifications in one shipment

- Offer discounts for bulk and repeat orders

For U.S. buyers, this means we can supply complete building projects in a single shipment, cutting down freight costs and lead times.

Export Documentation

We manage all essential paperwork for smooth customs clearance, including:

- Commercial Invoice & Packing List

- Bill of Lading

- Certificate of Origin

- Inspection & Quality Certificates (ISO, CE, SGS as required)

- Any special compliance document needed for U.S. import regulations

Shipping and Logistics Solutions

Major ports of shipment: Shanghai, Qingdao, Tianjin (China)

- Lead time: Typically 7–15 days after order confirmation for standard sizes; custom sizes may require longer

- Shipping methods: Full Container Load (FCL), Less than Container Load (LCL)

- We work with trusted freight forwarders experienced in U.S. imports, ensuring timely delivery

Incoterms Offered

We offer flexible trade terms to match your procurement process:

- FOB (Free on Board) – buyer handles main freight

- CIF (Cost, Insurance, and Freight) – we handle freight and insurance to your destination port

- EXW (Ex Works) – buyer picks up directly from our factory

Tip for U.S. buyers: Most of our American clients choose CIF for simplified handling, especially when importing large quantities of PU sandwich panels.

Why Buy from Shanghe Polyurethane Sandwich Panel China Exporter

Competitive Pricing

As a leading polyurethane sandwich panel manufacturer and exporter in China, Shanghe delivers factory-direct prices without cutting corners on quality. Our large-scale production and sourcing power let us offer better cost-per-square-foot rates than many local U.S. suppliers — ideal for contractors, distributors, and large-scale projects aiming to maximize return on investment.

OEM and ODM Services

We provide customized PU sandwich panel solutions tailored to your project needs. Whether you need specific dimensions, colors, facing materials, or branding for resale, our OEM and ODM capabilities ensure your polyurethane insulated panels align perfectly with your requirements. This means we can design and produce for cold storage builders, modular home suppliers, or industrial facility contractors with a quick turnaround.

After-sales Support and Warranty

Every shipment comes with full technical support, installation guidance, and a product warranty. If you encounter an issue, our U.S.-focused service team can advise in real-time via email, phone, or WeChat. We stand behind our polyurethane core panels with clear warranty terms, covering both performance and workmanship defects.

Customer Testimonials and Case Studies

Our PU foam sandwich panels have been successfully exported to the U.S., Canada, Europe, and the Middle East for projects like cold storage facilities, clean rooms, and prefabricated building systems. American customers value the consistency in panel quality, on-time deliveries, and cost savings. Many repeat buyers partner with us long-term because they’ve seen first-hand how our panels reduce energy bills, cut installation time, and last for decades.

Dedicated Export Team and Responsive Communication

Shanghe’s specialized export department handles everything from customs documentation to freight booking. We communicate clearly, in fluent English, with direct points of contact, so there’s no miscommunication during technical, packaging, or shipping discussions. Our team understands U.S. import requirements and can handle FOB, CIF, or EXW shipping terms to your requested port.

Key Reasons U.S. Buyers Choose Shanghe:

- Competitive factory-direct pricing

- Full customization (OEM/ODM) to match project specs

- Reliable warranty and tech support post-sale

- Proven export track record with U.S. clients

- Smooth logistics & documentation handling

FAQs for Polyurethane Sandwich Panel China Exporter

Common Buyer Questions about Polyurethane Sandwich Panels

Q: What sizes and thicknesses are available?

We offer polyurethane sandwich panels in 30mm to 150mm thicknesses, with length and width customizable based on your project needs. Standard widths are 1000mm and 1200mm for ease of shipping and installation.

Q: What’s the advantage of polyurethane panels compared to other insulation materials?

Polyurethane (PU) panels provide better thermal insulation due to their low thermal conductivity (around 0.018–0.024 W/m·K), making them more energy-efficient than EPS or rock wool panels.

Q: Are these panels safe for use in residential buildings?

Yes. Our PU sandwich panels comply with international fire safety and building codes, backed by ISO, CE, and SGS certifications. We can provide B1/B2 fire-rated panels depending on the application.

Q: Do they require special maintenance?

No. PU panels have a moisture-resistant core and coated steel/aluminum facings, so they are low-maintenance and built for long-term use in harsh environments.

Export Process and Documentation Queries

Q: Can you export to the United States and handle customs paperwork?

Yes. We regularly ship to the U.S. and can supply all necessary export documentation, including:

- Commercial invoice

- Packing list

- Bill of lading

- Certificate of origin

- Inspection certificate (if requested)

Q: What Incoterms do you offer?

We support FOB, CIF, and EXW from major Chinese ports such as Shanghai, Qingdao, and Tianjin. Door-to-door delivery can be arranged through our logistics partners.

Q: How long is the lead time for bulk orders?

Typical lead time is 10–20 days after deposit, depending on quantity, specifications, and production schedule.

Customization and Sample Requests Info

Q: Can the panels be customized for my project?

Absolutely. You can customize:

- Thickness & size

- Facing material (PPGI steel, galvanized steel, aluminum)

- Coating color according to RAL color chart

- Joint profiles (tongue-and-groove, overlapping)

Q: Do you offer free samples?

Yes. We can provide small cut-panel samples for quality checks. Freight cost is usually borne by the buyer, but refundable on confirmed bulk orders.

Q: Can you produce OEM or with my branding?

Yes. We offer OEM & ODM services including branded packaging, printed logos, and custom documentation to match U.S. buyer requirements.

Get a Quote for Polyurethane Sandwich Panels

We make it easy for you to get pricing, technical details, or customization options for our polyurethane sandwich panels. Whether you’re sourcing for a small project or a bulk commercial order, our export team responds quickly with accurate information so you can move forward without delays.

Easy Inquiry Form

Fill out our short online form with:

- Panel specifications (thickness, size, core material, facing material)

- Order quantity

- Destination port and shipping terms

- Special requirements for cold storage panels, roof panels, or custom designs

Once we receive your request, we’ll prepare a clear quotation including product details, pricing, lead time, and shipping options.

Direct Contact Information

Reach us directly for faster communication:

Our English-speaking export managers are available during both China Standard Time and U.S. business hours for quick coordination.

Invitation to Visit the Factory

If you need to see our production and quality control in person, we welcome you to visit our polyurethane sandwich panel china exporter. During your visit, you can:

- Inspect panel production lines

- Review quality certifications (ISO, CE, SGS)

- Discuss OEM and ODM options for your brand

- Check large-scale orders in-progress

We can also arrange sample panels shipped to your location in the United States so you can evaluate our insulation quality, panel strength, and surface finish before placing an order.

Tip: Many U.S. buyers first order sample panels to test R-value performance and ease of installation before committing to bulk shipments.