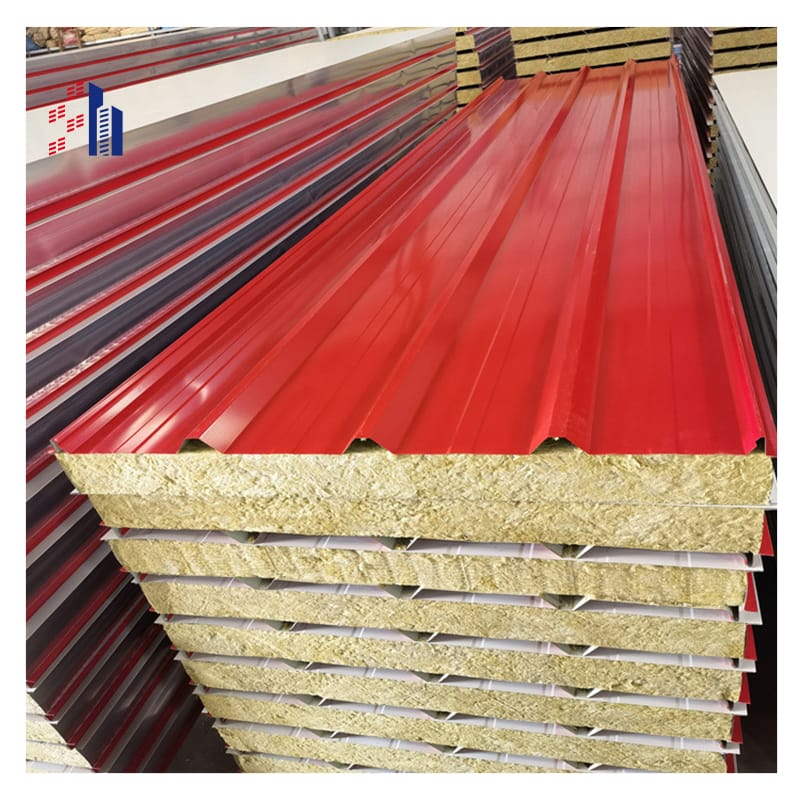

What are Rockwool Panels

Rockwool panels, also known as mineral wool insulation panels or stone wool panels, are high-performance insulation boards made from natural volcanic rock fibers. These panels are engineered to deliver superior thermal insulation, sound absorption, and fire resistance, making them an ideal choice for a wide range of construction and industrial applications. Renowned for their durability and non-combustible nature, rockwool panels help improve energy efficiency while enhancing acoustic comfort and safety in buildings.

Customers visit the factory

Installation details

Key Specifications

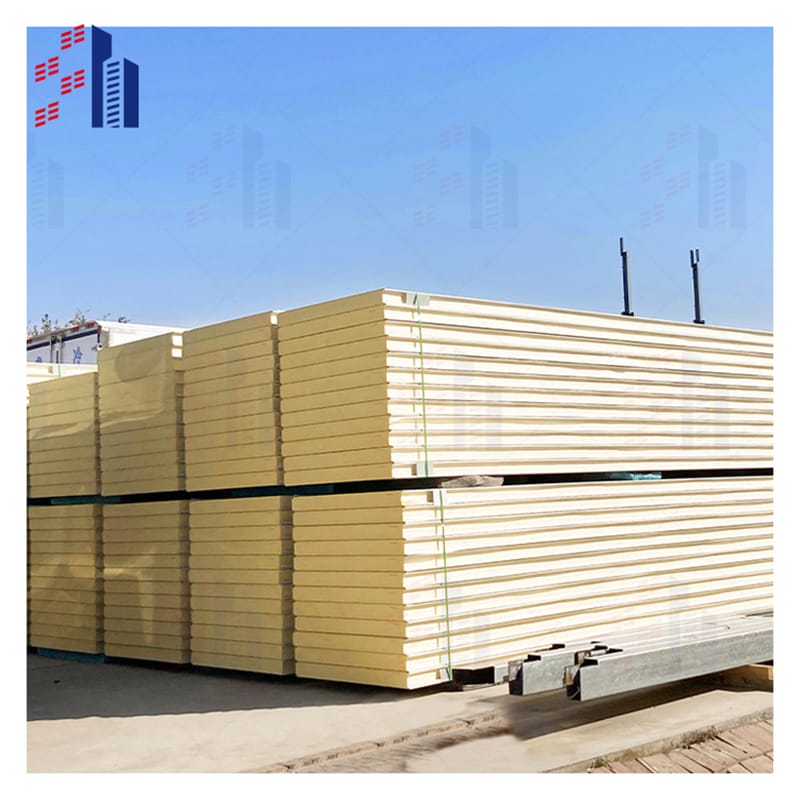

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Product Overview of Rockwool Panels

Introduction to Shanghe Rockwool Panels

Shanghe Rockwool Panels represent quality and innovation in the mineral wool industry. Manufactured using advanced production techniques, these panels offer consistent density and fiber structure to maximize performance. Shanghe’s rockwool insulation panels are designed to meet stringent international standards, including ISO, ASTM, and CE certifications, ensuring reliable and durable insulation solutions for residential, commercial, and industrial needs.

Key Advantages of Shanghe Rockwool Panels

- Exceptional Thermal Insulation: Shanghe rockwool panels feature a high R-value, providing excellent resistance to heat flow. This translates into effective temperature regulation that reduces energy consumption and lowers heating and cooling costs.

- Superior Sound Absorption: With their porous and fibrous structure, rockwool panels excel at dampening noise transmission. They are commonly used as acoustic insulation panels in studios, auditoriums, offices, and residential buildings to create quieter environments.

- Outstanding Fire Resistance: Made from naturally fire-resistant stone fibers, Shanghe rockwool panels are non-combustible and classified as Euroclass A1 fire-rated materials. This makes them critical for enhancing fire safety and protecting buildings from fire hazards.

- Moisture and Durability Resistance: These panels resist moisture retention, preventing mold growth and structural damage, which extends the lifespan of insulation systems.

Shanghe rockwool panels combine these key advantages to offer a reliable, environmentally friendly, and cost-effective insulation solution that meets the rigorous demands of modern construction and industrial projects.

Features and Benefits of Rockwool Panels

High Thermal Performance

Shanghe Rockwool Panels stand out for their excellent thermal insulation properties. With a high R-value, these panels effectively resist heat transfer, keeping your space warmer in the winter and cooler in the summer. This means reduced energy costs and a more comfortable indoor environment year-round.

Enhanced Sound Insulation

Thanks to their dense, fibrous structure, these soundproof rockwool panels provide superior acoustic insulation. They absorb sound waves efficiently, making them ideal for reducing noise pollution in homes, offices, studios, and commercial buildings.

Fireproof and Non-Combustible

Safety is a priority with rockwool. Shanghe Rockwool Panels are fire-resistant and non-combustible, conforming to rigorous fire safety standards like Euroclass A1. This characteristic helps contain fires and prevents toxic smoke, giving you peace of mind for residential or industrial applications.

Moisture Resistance and Durability

These panels resist water and moisture penetration, reducing the risk of mold and mildew growth. Their durability ensures long-lasting performance even in humid or damp environments, making them a reliable choice for various settings.

Environmentally Friendly Manufacturing

Shanghe Rockwool Panels are crafted using sustainable processes and recyclable materials. This eco-friendly production minimizes environmental impact, helping your project meet green building standards and contribute to a healthier planet.

Lightweight Yet Robust Construction

Despite their strength, these panels are surprisingly lightweight, which allows easier handling without compromising structural integrity. This balance between lightweight and robust design simplifies transport and on-site assembly.

Easy Installation Process

The panels are designed for quick and straightforward installation. Their uniform size and manageable weight mean you can install them with basic tools, saving time and labor costs on any project.

For more details on our rockwool panels and their specifications, please visit our Rock Wool Sandwich Panels page.

Technical Specifications of Rockwool Panels

When choosing rockwool panels for insulation or soundproofing, knowing the technical details helps you pick the right fit for your project. Here’s a clear breakdown of the key specs for Shanghe Rockwool Panels, covering size, performance, and certifications.

Dimensions and Density

- Thickness: Typically ranges from 25 mm to 100 mm, allowing flexibility for different insulation needs.

- Width: Standard panels come in 600 mm or 610 mm, matching most framing systems.

- Length: Panels are available in lengths up to 1200 mm or longer depending on customization.

- Density: Between 40 to 140 kg/m³, with higher density panels providing better sound absorption and structural strength.

Thermal Conductivity and R-value

- Thermal Conductivity: Low thermal conductivity around 0.035 to 0.040 W/m·K, making these panels effective thermal insulation boards.

- R-value: Depending on thickness, R-values can range from R-3.5 to R-12, contributing significantly to energy savings by reducing heat loss or gain.

Fire Rating and Safety Standards

- Fire Rating: Certified as Euroclass A1 (non-combustible) per EN 13501-1, meaning these are top-tier fire resistant insulation panels ideal for building code compliance and safety.

- Non-combustible: Rockwool panels do not ignite or contribute to flame spread, ensuring reliable fire protection.

Acoustic Performance

- Acoustic Absorption Coefficients: Shanghe rockwool panels offer superior soundproofing, with coefficients typically ranging from 0.70 to 1.00 in the mid to high-frequency range, efficient for acoustic insulation panels needs.

- Ideal for reducing noise in studios, commercial spaces, and residential areas.

Industry Standards and Certifications

- Compliant with major certifications:

- ISO 9001 for quality management.

- ASTM C665 and ASTM C423 for thermal and acoustic properties.

- CE marking complying with EU safety standards.

- Meets building codes across the United States requiring sustainable and safe insulation materials.

Choosing Shanghe Rockwool Panels means you get a product tested and certified to deliver consistent thermal insulation, sound absorption, and fire safety — all essentials for American homes and businesses looking for reliable and compliant insulation solutions.

Applications of Rockwool Panels for Insulation and Soundproofing

Rockwool panels are a versatile choice for various applications across residential, commercial, and industrial sectors thanks to their excellent thermal insulation, sound absorption, and fire resistance. Here’s how they fit into different settings:

Residential Use

Ideal for walls, ceilings, and floors, rockwool panels help improve comfort by keeping indoor temperatures stable and reducing noise between rooms. Their fireproof nature adds an extra safety layer, making them a smart option for homes focusing on energy efficiency and safety.

Commercial Buildings

In offices, malls, and hospitals, these stone wool panels provide effective thermal insulation and acoustic control to create comfortable, quiet, and safe environments. They help lower energy costs while meeting strict fire safety standards, which is critical in high-occupancy spaces.

Industrial Environments

Factories and power plants benefit from rockwool’s durability and fire resistance. These panels protect against extreme temperatures and noise, making them perfect for harsh industrial conditions that require non-combustible insulation materials with long-lasting performance.

HVAC Systems and Duct Insulation

Rockwool panels are widely used in HVAC systems to insulate ductwork, preventing heat loss or gain and reducing noise from air circulation. Their moisture resistance keeps the system efficient and free from mold, which is essential for maintaining indoor air quality.

Soundproofing Studios and Auditoriums

Thanks to their excellent acoustic absorption properties, rockwool panels are commonly installed in soundproofing applications like music studios, theaters, and auditoriums. They minimize sound transmission and improve room acoustics, ensuring clear, undisturbed sound quality.

For tailored rockwool insulation panel solutions, explore options like our mineral rock wool insulated panels designed for commercial and industrial use. Whether your project demands thermal insulation or soundproofing, rockwool panels offer reliable, sustainable performance across many sectors.

Installation Guidelines for Rockwool Panels

Preparation and Required Tools

Before starting the installation of rockwool panels, make sure you have everything ready:

- Protective gear: gloves, mask, and safety glasses to avoid irritation from mineral wool fibers

- Measuring tape and marker for precise cutting

- Utility knife or insulation saw for trimming panels

- Straightedge or T-square for clean cuts

- Staple gun or mechanical fasteners for securing panels

- Sealant or adhesive suitable for rockwool boards when needed

- Ladder or scaffolding for ceiling or high wall installations

Having these tools on hand ensures a smooth and efficient setup of your thermal insulation boards and soundproof rockwool panels.

Step-by-step Installation Process

- Surface Preparation: Clean and dry the installation area. Ensure walls, ceilings, or duct surfaces are free from dust and moisture.

- Measure and Cut: Use your tape measure to size each panel carefully. Cut with a utility knife or insulation saw using a straightedge for neat, accurate edges.

- Panel Placement: Fit the panels snugly between studs or joists. For HVAC duct insulation, wrap panels firmly around ducts ensuring no gaps.

- Secure the Panels: Use staples or mechanical fasteners to hold the rockwool panels in place. Make sure they are tight but not compressed to maintain thermal and acoustic performance.

- Seal Joints and Edges: Apply sealant or tape to joints to prevent air leaks and improve fire resistance.

- Finish Surface: Where applicable, install drywall or other finishes over the panels per your overall building plan.

Safety Precautions

- Always wear proper protective equipment while handling rockwool—this minimizes skin and respiratory irritation.

- Work in well-ventilated areas.

- Avoid compressing panels to maintain their thermal insulation and sound absorption qualities.

- Follow local building codes especially for fire safety and installation standards related to non-combustible insulation materials.

Maintenance and Longevity Tips

- Rockwool panels are naturally moisture-resistant and durable; however, check periodically for signs of moisture or physical damage.

- Avoid exposure to prolonged wet conditions—ensure proper vapor barriers where required.

- Maintain clean surfaces; dust buildup can reduce acoustic efficiency.

- Address any damaged sections promptly by replacing panels to keep insulation and fireproofing effective.

- Proper installation leads to long-lasting thermal and acoustic performance often lasting decades with minimal upkeep.

By following these guidelines, you can maximize the effectiveness and life of your Shanghe rockwool insulation panels, ensuring superior performance in energy efficiency, soundproofing, and fire protection throughout your home or commercial space.

Why Choose Shanghe Rockwool Panels

When it comes to rockwool panels for insulation, soundproofing, and fire resistance, Shanghe Rockwool Panels stand out in the U.S. market for several solid reasons.

Superior Quality Control and Testing

Shanghe takes quality seriously. Every batch of Shanghe rockwool insulation panels goes through strict testing to ensure consistent performance. This means:

- Reliable thermal insulation with stable R-values

- Excellent sound absorption verified by acoustic testing

- Fire resistance certified to Euroclass A1, proving non-combustibility

- Moisture resistance to prevent mold and decay

These quality checks guarantee you get durable, safe, and high-performing stone wool panels every time.

Competitive Pricing and Value for Money

Shanghe offers rockwool panels at competitive prices without cutting corners on quality. That balance means you get:

- High-performance thermal and acoustic insulation

- Durable construction that lasts for decades

- Affordable options for residential, commercial, and industrial projects

You don’t have to pay premium prices to get fire-resistant insulation panels that meet U.S. building standards and perform under real-world conditions.

Customer Testimonials and Case Studies

We stand by our products, and many customers across the U.S. have shared positive feedback including:

- Builders praising easy installation and reliable insulation

- Facility managers noting improved HVAC efficiency and lowered energy bills

- Architects appreciating the panels’ lightweight yet robust feel

Real projects back our claims—from residential walls to soundproof studios, Shanghe rockwool panels deliver results you can count on.

After-Sales Support and Warranty

Buying Shanghe mineral wool insulation panels means you’re not left on your own. We provide:

- Responsive customer service to answer technical questions

- Support for product selection and installation guidance

- A warranty that covers manufacturing defects and performance

This dependable after-sales support ensures you get long-term value and peace of mind with your purchase.

Choosing Shanghe rockwool panels means picking proven quality, good value, trusted performance, and a brand that supports you beyond the sale. Whether you’re insulating a home, office, or industrial space, Shanghe panels meet the high expectations of U.S. customers looking for reliable, sustainable, and effective insulation solutions.

Frequently Asked Questions About Rockwool Panels

What Makes Rockwool Panels Better Than Fiberglass

Rockwool panels stand out compared to fiberglass for several reasons:

- Fire resistance: Rockwool is naturally non-combustible with a Euroclass A1 fire rating, providing superior fire protection over fiberglass.

- Sound absorption: Rockwool offers higher density and better acoustic insulation, making it excellent for noise control in homes and commercial spaces.

- Moisture resistance: Unlike fiberglass, rockwool panels resist mold and mildew, reducing health risks and prolonging durability.

- Thermal performance: Rockwool generally provides better insulation (higher R-values), helping to keep indoor temperatures stable.

How Do Rockwool Panels Improve Energy Efficiency

Shanghe rockwool panels enhance energy efficiency by:

- Reducing heat transfer through walls, ceilings, and floors, which lowers heating and cooling costs.

- Maintaining stable indoor temperatures even under extreme weather conditions.

- Being moisture resistant, they prevent insulation degradation, keeping thermal performance consistent over time.

Are Shanghe Rockwool Panels Safe to Handle

Yes, shanghe rockwool panels are safe to handle when you follow basic safety steps:

- Always wear gloves, long sleeves, and eye protection to avoid skin irritation from fibers.

- Cutting panels produces minimal dust; use a mask for extra protection.

- Once installed, panels pose no health risks—they don’t release harmful chemicals or fibers.

Can Rockwool Panels Be Recycled

Yes, rockwool insulation panels are recyclable.

- The mineral wool fibers can be reused in manufacturing new insulation products.

- Many recycling facilities accept rockwool waste, reducing landfill impact.

- Choosing recyclable insulation supports environmentally friendly and sustainable building practices.

What Is the Expected Lifespan of Rockwool Panel

- Shanghe rockwool panel typically last 30 to 50 years or more with proper installation and maintenance.

- Their durability comes from moisture resistance, fireproof nature, and robust construction.

- Regular inspections help ensure performance and allow early detection of any damage.

By understanding these FAQs, you can make an informed decision about choosing shanghe rockwool panel for your next project. They combine durability, safety, and efficiency tailored to the needs of the U.S. market.

Purchase Information for Rockwool Panel

Available Sizes and Packaging Options

Shanghe Rockwool Panel come in a variety of standard sizes to fit most insulation and soundproofing needs across residential, commercial, and industrial projects. Common dimensions include:

- Thickness: 25mm to 100mm

- Width: 600mm (standard panel width)

- Length: 1200mm to 2400mm

Panels are typically packaged in shrink-wrapped bundles, with quantities depending on panel size and thickness to ensure safe transport and handling. Custom sizes and sandwich panel options are also available upon request.

Ordering Process and Minimum Order Quantities

Ordering Shanghe Rockwool Panel is straightforward:

- Contact our sales team via phone or email for quotes and product consultation.

- Provide project details including quantity, size preferences, and delivery location.

- Minimum order quantities vary by product type but generally start at 100 square feet per order.

- Larger bulk orders and custom requirements are welcomed, especially for commercial and industrial clients.

Shipping and Delivery Details

We offer nationwide shipping across the United States with flexible delivery options to fit your schedule. Key points include:

- Fast processing time with orders typically shipped within 3-5 business days.

- Options for freight or parcel delivery depending on order size.

- Tracking information provided after shipment for real-time updates.

- Packaging is designed to protect the panels from moisture and damage during transit.