Why Choose Shanghe Rockwool Sandwich Panels for Your Construction Needs

When it comes to choosing insulation for your building projects, I know safety, efficiency, and durability are top priorities. That’s why Shanghe Rockwool Sandwich Panels are a smart choice for any construction need. These panels combine rockwool insulation with strong, fireproof sandwich panel design, offering unmatched performance for both commercial and industrial buildings.

Here’s why Shanghe stands out:

- Fireproof and Non-Combustible – Shanghe rockwool insulation panels resist fire, giving your building superior protection and peace of mind.

- Excellent Thermal Insulation – Keep energy costs down with rockwool panels designed to maintain stable indoor temperatures even in extreme weather.

- Sound Absorption – The acoustic rockwool layers reduce noise, making these panels great for noisy industrial sites or commercial spaces.

- Durable and Long-Lasting – Shanghe’s sandwich panels are built to withstand harsh environments without losing performance.

- Sustainable Materials – Made from stone wool, these panels contribute to green building goals while delivering top-tier insulation.

- Easy to Install – Designed with smooth installation in mind, their panels help speed up construction without compromising quality.

If you want construction materials that bring safety, efficiency, and sustainability to the table, Shanghe Rockwool Sandwich Panels are worth considering for your next project.

Customers visit the factory

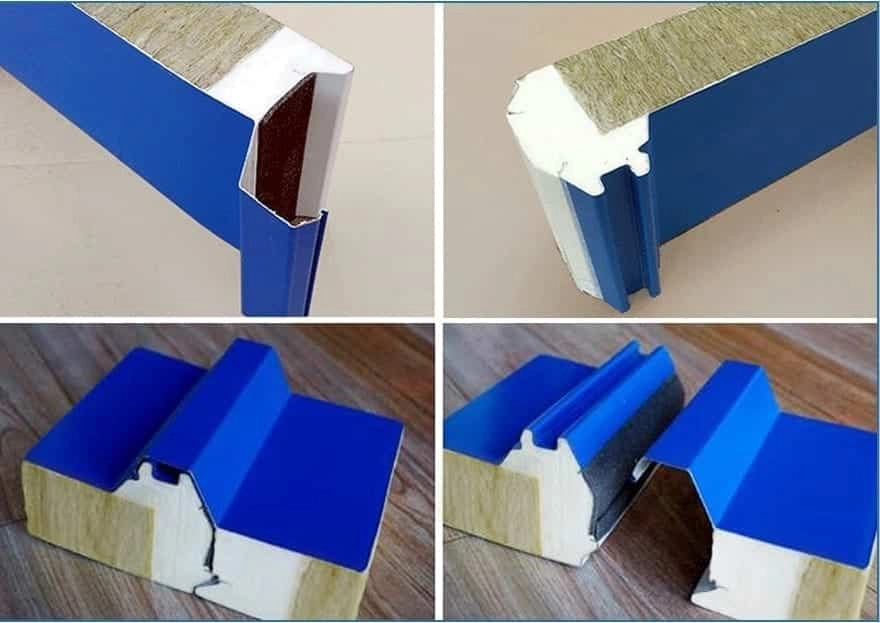

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

What Are Rockwool Sandwich Panels

Rockwool sandwich panels are a type of building material made by sandwiching a core of rockwool insulation between two metal sheets. Rockwool, also called stone wool, is a non-combustible material made from natural volcanic rock spun into fibers. This core provides excellent thermal insulation, fire resistance, and soundproofing, making the panels perfect for energy-efficient construction.

These panels serve as wall or roof cladding and are widely used in industrial buildings, commercial spaces, and even residential projects. The metal facings protect the rockwool core, adding strength and durability to the panel. Because of the combination of materials, rockwool sandwich panels deliver superior fireproof and acoustic performance compared to many traditional insulation options.

In short, rockwool sandwich panels give you a reliable, safe, and energy-saving solution that fits well in modern construction, especially when fire safety and sound control are top priorities.

Key Benefits of Shanghe Rockwool Sandwich Panels

Shanghe Rockwool sandwich panels bring a lot to the table for construction projects across the U.S. Here’s why they stand out:

Fireproof and Non-Combustible

Rockwool insulation panels are naturally fire-resistant. Shanghe panels meet strict fire safety standards, giving you peace of mind with non-combustible building panels that protect your property and people.

Excellent Thermal Insulation

These energy-efficient wall panels keep your building warmer in winter and cooler in summer, lowering heating and cooling costs. Their stone wool core traps air for superior thermal performance.

Sound Absorption

Acoustic rockwool panels help reduce noise pollution, making them ideal for industrial buildings, offices, and even residential areas near busy roads or airports.

Durability and Moisture Resistance

Shanghe panels resist mold, mildew, and moisture buildup, helping them last longer in humid climates and reducing maintenance costs.

Lightweight but Strong

They’re easy to handle on-site without sacrificing strength, speeding up installation while providing solid structural support.

Sustainable and Eco-Friendly

Made from natural volcanic rock, these panels align with sustainable construction materials goals. Plus, they can be recycled at the end of their service life.

Versatile Applications

Whether you’re working on warehouses, commercial buildings, or cold storage, their flexible design suits a variety of construction needs.

In short, choosing Shanghe Rockwool sandwich panels means investing in safe, efficient, and sustainable insulation that suits the specific demands of U.S. construction projects.

Applications of Shanghe Rockwool Sandwich Panels

Shanghe Rockwool Sandwich Panels are perfect for many construction projects across the U.S., especially where fire safety and energy efficiency matter. Here’s where they shine:

- Industrial Building Insulation: Ideal for factories and warehouses, these panels provide strong thermal insulation and are fireproof, reducing risks and saving on energy costs.

- Commercial Buildings: From office spaces to retail stores, the panels improve sound control with acoustic rockwool insulation, creating quieter, more comfortable environments.

- Cold Storage Facilities: Their excellent thermal insulation keeps temperatures steady, making them a go-to choice for refrigerated warehouses or food processing plants.

- Agricultural Structures: Farms and greenhouses benefit from durable stone wool sandwich panels that resist moisture and pests while maintaining proper climate control.

- Public and Institutional Buildings: Schools, hospitals, and government facilities use these non-combustible building panels to meet strict fire codes without sacrificing insulation quality.

- Residential Projects: For homes needing energy-efficient wall panels, these rockwool panels offer both insulation and soundproofing, improving comfort and lowering utility bills.

- Renovations and Retrofits: Their ease of installation and lightweight design make Shanghe rockwool sandwich panels excellent for upgrading older buildings to modern energy and safety standards.

In short, whether you’re working on commercial, industrial, or residential projects, Shanghe Rockwool Sandwich Panels deliver reliable performance that meets local building codes and environmental expectations.

Why Shanghe Stands Out as a Rockwool Panel Manufacturer

Shanghe has built a strong reputation as a leading rockwool panel manufacturer by focusing on quality, innovation, and customer satisfaction. Here’s why they stand out in the crowded market:

- Quality Materials: Shanghe uses top-grade rockwool insulation panels, ensuring fireproof sandwich panels that are durable and reliable for any construction project.

- Advanced Production: Their state-of-the-art technology guarantees consistent thickness, density, and thermal performance across every stone wool sandwich panel.

- Customization Options: Shanghe offers tailored panel sizes and core thickness to fit specific project needs, making installation straightforward and efficient.

- Strong Support Network: They provide expert guidance on rockwool panel installation and post-sale assistance, helping U.S. contractors and builders get the most out of their products.

- Sustainability Focus: Shanghe’s panels emphasize energy-efficient wall panels and sustainable construction materials, meeting the growing demand for eco-friendly building solutions in the U.S.

- Competitive Pricing: With affordable pricing without compromising quality, Shanghe makes high-performance non-combustible building panels accessible for various budgets.

Whether you’re working on industrial building insulation or residential projects, Shanghe’s commitment to innovation and quality makes them a trusted choice for rockwool sandwich panels in the United States.

Comparing Rockwool Sandwich Panels to Other Insulation Materials

When choosing insulation for your construction project, it’s important to see how rockwool sandwich panels stack up against other options like foam, fiberglass, or PIR panels. Here’s a quick breakdown to help you understand why Shanghe Rockwool Sandwich Panels stand out.

Fire Resistance

Rockwool insulation panels are naturally fireproof and non-combustible, offering superior fire protection compared to foam panels, which can melt or release toxic fumes. This makes rockwool ideal for buildings where safety is a top priority.

Thermal Performance

While foam panels provide good insulation, rockwool panels offer stable thermal insulation that holds up well under temperature changes. They help keep energy costs down by maintaining consistent indoor temperatures.

Sound Insulation

Acoustic rockwool panels outperform many alternatives when it comes to reducing noise. Their dense fiber structure absorbs sound effectively, making them perfect for industrial building insulation or office spaces needing quieter environments.

Durability and Moisture Resistance

Rockwool panels resist moisture and don’t support mold growth. Unlike fiberglass or foam, they maintain their integrity even in damp conditions, reducing long-term maintenance costs.

Environmental Impact

Made from natural stone fibers, rockwool panels are more sustainable than petroleum-based foam insulation. They are recyclable and contribute to eco-friendly, sustainable construction materials.

Cost Consideration

Though rockwool sandwich panels might have a higher upfront cost, their durability, fire safety, and energy efficiency often lead to savings over the life of the building.

For a closer look at different panel options, check out our fireproof sandwich panel product or explore our range of building sandwich panels for your project needs.

Technical Specifications of Shanghe Rockwool Sandwich Panels

Shanghe Rockwool Sandwich Panels are designed to meet the tough demands of construction in the U.S. market, combining durability with effective insulation. Here’s a simple breakdown of their core specs:

- Core Material: High-density rockwool (stone wool) insulation for excellent thermal and acoustic performance

- Panel Thickness: Ranges from 50mm to 150mm, adjustable to your project’s insulation needs

- Facing Materials: Galvanized or color-coated steel sheets, available in different finishes for corrosion resistance

- Fire Rating: Non-combustible rockwool core provides Class A fire rating, making it ideal for fireproof sandwich panels

- Thermal Conductivity: Low thermal conductivity value (around 0.035 W/m·K), ensuring strong energy-efficient wall panels

- Sound Insulation: High noise reduction coefficient, perfect for industrial building insulation and acoustic rockwool panels

- Panel Length and Width: Customizable up to 12 feet long and 3 feet wide to fit varied construction needs

- Weight: Lightweight yet sturdy, simplifying rockwool panel installation and handling on-site

These specs make Shanghe Rockwool Sandwich Panels a smart choice when you want reliable fireproof, thermal insulation construction that stands up to U.S. building standards without costing more or slowing your project down.

How to Install Shanghe Rockwool Sandwich Panels

Installing Shanghe Rockwool Sandwich Panels is straightforward and designed to fit most construction projects in the U.S. Here’s a simple guide to get you started:

1. Prepare the Surface

- Make sure your structure’s framework is clean, level, and sturdy.

- Check for any gaps or damage that might affect panel installation.

2. Handling the Panels

- Use gloves and proper lifting tools to avoid damaging the rockwool insulation panels.

- Store panels in a dry area to keep the stone wool core in optimal condition.

3. Positioning the Panels

- Align the panels carefully for a tight fit.

- Rockwool sandwich panels are typically installed horizontally or vertically based on your project design.

4. Fixing the Panels

- Secure the panels with screws or fasteners recommended by Shanghe.

- Use sealing strips or foam to fill any small gaps to maintain thermal and acoustic insulation.

5. Sealing and Finishing

- Apply waterproof sealants around edges to prevent moisture intrusion.

- Double-check panel joints to ensure airtight installation.

6. Safety Tips

- Wear protective gear like gloves and masks during installation.

- Follow local building codes for fireproof sandwich panels and insulation installation.

By following these steps, you ensure maximum performance from your Shanghe rockwool sandwich panels in thermal insulation construction and fireproofing. Proper installation helps keep buildings energy-efficient and durable.

Environmental and Cost Benefits of Choosing Shanghe Rockwool Sandwich Panels

When you choose Shanghe rockwool sandwich panels, you’re making a smart choice for both your budget and the environment. These panels use stone wool insulation, a sustainable construction material that’s eco-friendly and fully recyclable. They help reduce energy use by improving thermal insulation, which means lower heating and cooling bills for your building.

Here’s what makes Shanghe panels a win for your wallet and the planet:

- Energy Efficiency: The superior thermal insulation cuts down on energy consumption, saving money over time.

- Fire Safety: Being non-combustible building panels, they reduce fire risk, potentially lowering insurance costs.

- Durability: Long-lasting materials mean fewer replacements and less waste.

- Sustainable Manufacturing: Shanghe focuses on environmentally responsible production methods.

- Reduced Carbon Footprint: Better insulation means less reliance on fossil fuels for climate control.

All these benefits combine to give you a cost-effective, green solution perfect for U.S. commercial and industrial projects looking for reliable, high-performance rockwool panel insulation.

Real-World Case Studies and Success Stories

Let’s look at how Shanghe rockwool sandwich panels have performed in real projects across the U.S. These stone wool sandwich panels have helped many industrial and commercial buildings stay safe, energy-efficient, and comfortable.

Case Study 1: Industrial Warehouse in Texas

A large warehouse needed better thermal insulation and fireproofing. Shanghe’s rockwool insulation panels were installed, cutting cooling costs by 30% and significantly improving fire resistance. The non-combustible building panels gave the facility peace of mind during fire safety inspections.

Case Study 2: Office Building Retrofit in California

This office building suffered from poor sound insulation and high energy bills. By upgrading to acoustic rockwool panels, they reduced noise transfer and improved HVAC efficiency. The energy-efficient wall panels helped lower monthly energy costs.

Case Study 3: Sustainable School Construction in Oregon

For a new sustainable school project, builders chose Shanghe’s rockwool sandwich panels. The panels provided excellent thermal and acoustic insulation while meeting green building standards. The project showcased how sustainable construction materials can perform well and protect occupants.

These success stories highlight why Shanghe is trusted by U.S. builders looking for reliable, fireproof sandwich panels that perform under real conditions. For your next construction project, these rockwool panel installations prove they deliver lasting value.

Frequently Asked Questions About Rockwool Sandwich Panels

What are Rockwool sandwich panels made of?

They’re made by sandwiching a core of rockwool insulation between two durable metal sheets. Rockwool, also called stone wool, is a fireproof, non-combustible material made from volcanic rock.

Are Shanghe Rockwool panels fire-resistant?

Yes, they are fireproof sandwich panels designed to meet strict fire safety standards. They help prevent fire spread, making them ideal for industrial and commercial buildings.

How do Rockwool sandwich panels improve energy efficiency?

The rockwool insulation offers excellent thermal insulation, keeping buildings cooler in summer and warmer in winter. This reduces HVAC costs and boosts energy efficiency.

Can these panels help with noise reduction?

Absolutely. Acoustic rockwool panels are great for soundproofing. They absorb sound waves, reducing noise pollution inside your building.

Where are Rockwool sandwich panels commonly used?

They’re popular in industrial building insulation, warehouses, cold storage, commercial buildings, and sustainable construction projects.

How difficult is it to install these panels?

Installation is straightforward. Panels are lightweight and easy to handle, with simple fixing methods suited for quick construction or renovation.

Are Rockwool sandwich panels environmentally friendly?

Yes, rockwool is made from natural materials and can be recycled, fitting well with sustainable construction goals.

How long do these panels last?

They’re durable and resistant to weather, pests, and mold, providing long-term performance for your building.

Can I use Rockwool panels for walls and roofs?

Yes, they work perfectly as energy-efficient wall panels and roofing insulation solutions.

Why choose Shanghe for Rockwool panels?

Shanghe offers high-quality panels backed by strong customer support, competitive pricing, and tailored solutions for the US market.

If you have more questions, reach out to us anytime!

Contact Shanghe for Your Rockwool Sandwich Panel Needs

Ready to upgrade your construction project with quality rockwool panel sandwich solutions? At Shanghe, we make it easy to get the right fireproof sandwich panels that fit your budget and requirements. Whether you need help selecting the perfect thermal and acoustic rockwool panels or guidance on installation, our team is here to support you every step of the way.

Why reach out to Shanghe?

- Expert advice tailored to U.S. building codes and standards

- Customized options for industrial building insulation or commercial projects

- Fast quotes and reliable delivery nationwide

- Dedicated support for sustainable construction materials and energy-efficient wall panels

Get in touch today to discuss your project and discover how Shanghe rockwool sandwich panels can add value, safety, and efficiency. Contact us by phone, email, or through our website—we’re ready to help you build smarter and safer.