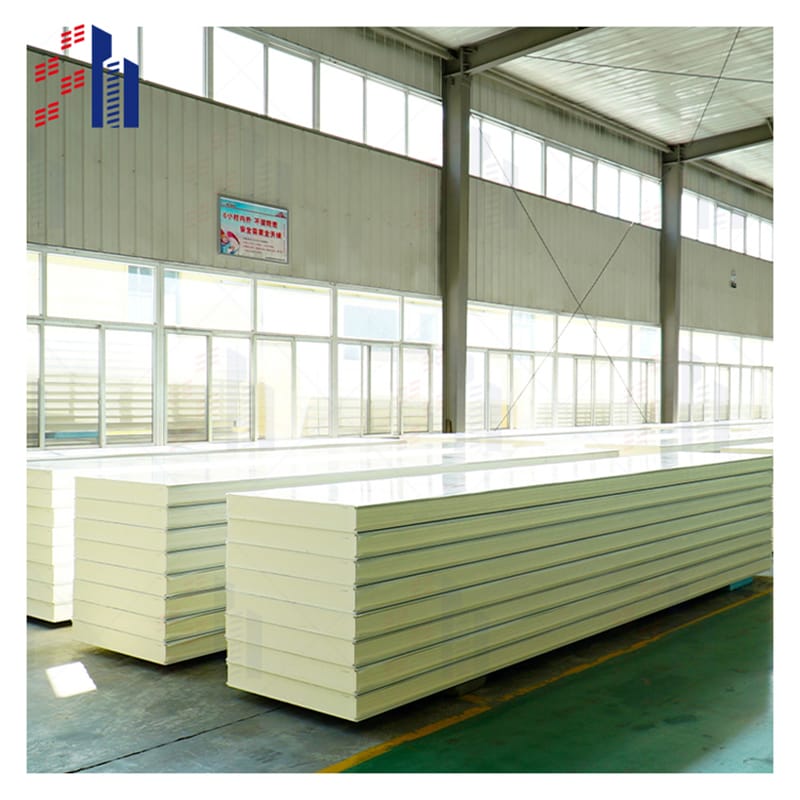

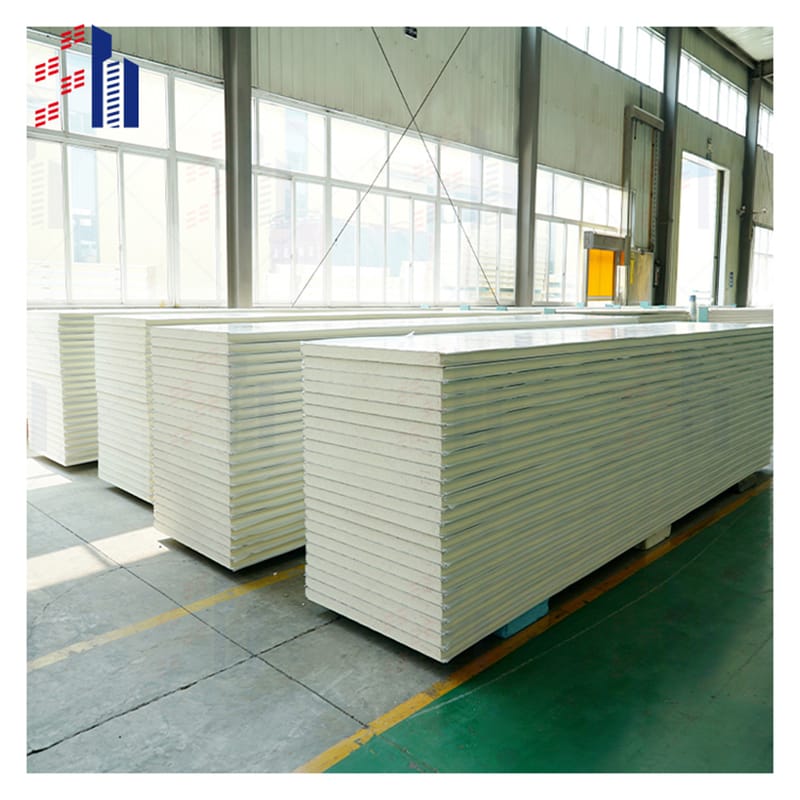

Customers visit the factory

Why Your Roof Panel Sandwich Fails – 20 Years of Expert Insights from David”

Let’s be honest—if your roof panel sandwich isn’t holding up, it’s probably due to poor material choice or installation mistakes. With 20 years in the sandwich panel industry, I’ve seen roofs leak, dent, and even collapse because folks cut corners. The right roof panel sandwich should be waterproof, durable, and perfectly fitted—no exceptions.

Here’s the deal: most failures happen when people ignore sandwich panel roof thickness or skip proper waterproofing. I’ve worked with LEED-certified builders who swear by high-density PUF cores because they prevent thermal bridging (that’s fancy talk for energy leaks). And trust me, if you’re in a place like the Philippines or Sri Lanka with heavy rain, a weak roof won’t last a monsoon season.

So, before you Google “sandwich panel roof near me”, ask yourself: Does this supplier understand load-bearing needs? Are they using metal sandwich panel roof tech that resists corrosion? Because if not, you’re just buying a fancy-looking problem.

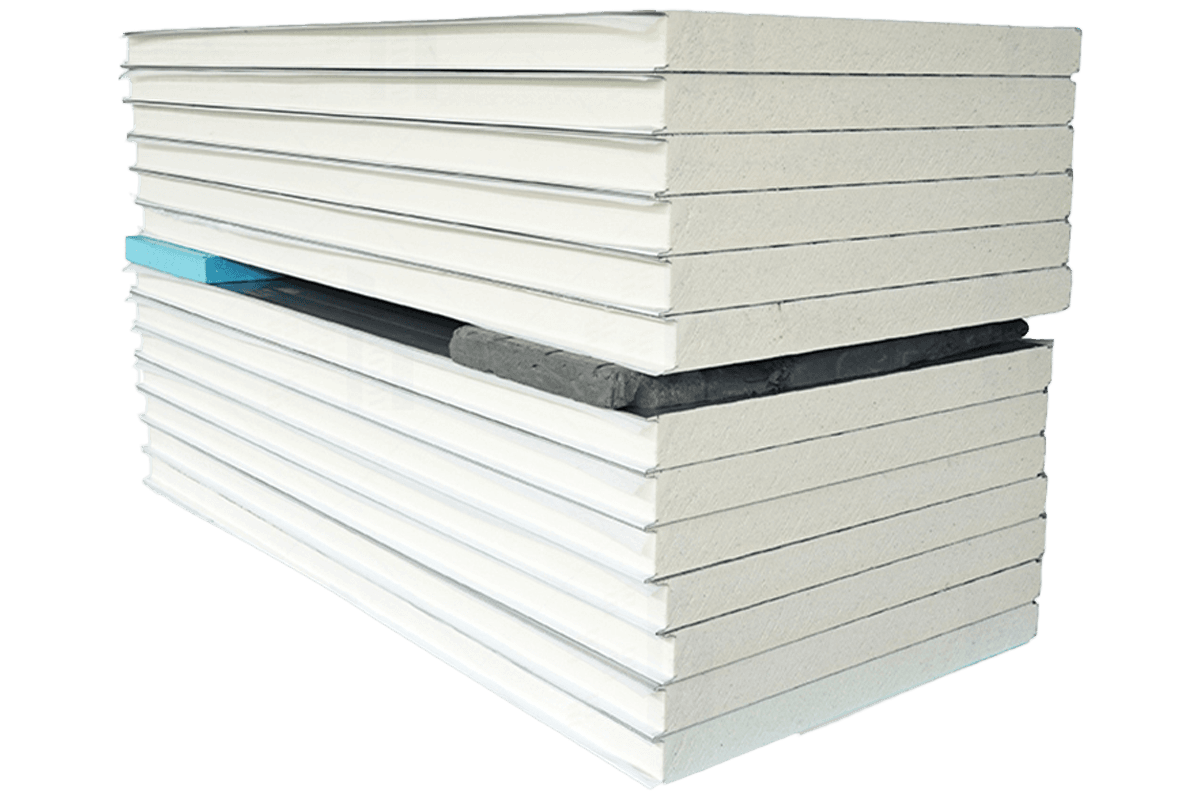

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | PIR (Polyisocyanurate) / Mineral Wool / EPS | EN 14509, ASTM C1289 |

| Thickness | 50mm, 75mm, 100mm, 120mm (Custom: 30-200mm) | ISO 9001 |

| Fire Rating | A1 (Non-combustible) / B1 (Self-extinguishing) | EN 13501, ASTM E84 |

| Thermal Conductivity | 0.022 W/mK (PIR) / 0.038 W/mK (Rockwool) | ISO 8301 |

| Load Capacity | Up to 150kPa (Snow) / 3,500 Pa (Wind) | ASTM E330, EN 14509 |

| Panel Width | 1,000mm (Standard), Custom 600-1,200mm | EN 10143 |

| Surface Coating | Galvalume (AZ150) + PVDF (25m) | AAMA 2605 |

| Color Options | 30+ RAL Colors (Glossy/Matte) | RAL Classic |

| Installation | Hidden Clip / Overlap System | FM Global Approval |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | mdf sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Here’s How to Avoid Costly Mistakes (David’s 20-Year Guide)

Looking for “sandwich panel roof near me”? Hold on—don’t just pick the closest supplier. After two decades in this game, I’ve seen too many clients get burned by local vendors selling low-grade panels that warp in heat or crack under snow loads.

The trick? Check three things:

Material – Are they using sandwich PUF roof panel cores, or cheap EPS that absorbs water?

Installation – Even the best panels fail if installed wrong. Ask for proof of past projects.

Warranty – No warranty? Walk away.

Fun fact: A study by the National Roofing Contractors Association found that 85% of roof failures trace back to installation errors. So yeah, location matters, but quality matters more.

What Contractors Won’t Tell You (David’s Insider Tips)

Bad sandwich panel roof design = leaks, poor insulation, and ugly gaps. As someone who’s designed roofs from Texas to Sri Lanka, here’s the truth: most contractors just slap panels together without considering pitch, drainage, or thermal expansion.

For example, in sandwich panel roof Philippines projects, I always recommend raised seams to handle typhoon-level rain. And if you’re using metal sandwich panel roof systems, make sure they’re coated to resist salt corrosion near coasts.

Pro tip: The best designs follow LEED guidelines for energy efficiency. Translation? Lower bills, happier clients.

Beat the Heat & Monsoons (David’s Survival Guide)

In the sandwich panel roof Philippines market, you need panels that laugh at humidity and shrug off UV rays. Most local suppliers use thin, uncoated metal that rusts in a year—but there’s a better way.

Go for sandwich PUF roof panel cores with a waterproofing membrane (like TPO or PVC). I’ve installed these in Cebu, and even after 10 years, zero leaks. Bonus: They reflect heat, so your attic isn’t an oven.

Remember: Thickness matters. Under 50mm? You’re basically using tinfoil.

Why It’s the #1 Choice for Extreme Weather (Tested by David)

If your sandwich PUF roof panel isn’t polyurethane foam (PUF), you’re missing out. PUF has the highest R-value (that’s insulation power) of any core—perfect for places like Sri Lanka or Arizona where temps swing wildly.

I once replaced a client’s EPS panels with PUF, and their cooling costs dropped 30%. Plus, PUF won’t absorb water like cheaper foams, so no mold surprises.

The $10,000 Mistake You’re Making (David Explains)

News flash: Sandwich panel roof waterproofing isn’t optional. I’ve repaired roofs where water seeped through seams and rotted the entire structure. The fix? Butyl tape on joints and a liquid-applied membrane (like Polyurea) for full coverage.

A MIT study proved that proper sealing extends roof life by 15+ years. So skip the silicone caulk—it cracks.

How Thin Is Too Thin? (David’s Rule of Thumb)

Choosing sandwich panel roof thickness? Here’s my rule: Under 75mm for roofs is like wearing a t-shirt in a snowstorm. In Sri Lanka, I use 100mm PUF panels to block heat. Thicker panels also handle wind uplift better—key for hurricane zones.

Why ‘One-Size-Fits-All’ Is a Lie (David’s Sizing Guide)

Wrong sandwich panel roof sizes waste money and time. For example, 1m-wide panels speed up installation, but 1.2m widths reduce seams (and leaks). Always match sizes to your roof’s span—or expect sagging.

How to Stop Rust & Leaks (David’s Battle-Tested Fixes)

In Sri Lanka, salt air eats cheap metal panels alive. Solution? Galvalume-coated metal sandwich panel roof systems with PUF cores. I’ve used these for beach resorts—zero corrosion after 8 years.

The Good, Bad & Ugly (20-Year Honest Review by David)

A metal sandwich panel roof can last decades… or fail in months. The difference? Steel grade. Go for G-300 or higher, and avoid rivet-only installations (welded seams last longer).

Fun fact: The Burj Khalifa uses similar tech. So yeah, it works—if you do it right.