Shanghe is a sandwich panel china, delivering high-quality insulated building materials to global markets. For over 20 years, we have specialized in producing PU (Polyurethane), PIR (Polyisocyanurate), EPS (Expanded Polystyrene), and Rock Wool sandwich panels that meet international thermal insulation, fire safety, and structural standards. Our panels are used in industrial, commercial, and residential construction projects across Asia, Europe, the Middle East, and the Americas.

20 Years of Sandwich Panel China

Since our founding, Shanghe has built a reputation as one of the most trusted sandwich panel manufacturers in China. We combine advanced Chinese manufacturing technology, strict quality control, and international certifications such as ISO, CE, and SGS to ensure consistent performance. Over two decades, we have supplied thousands of projects, from energy-efficient warehouses to high-standard cleanrooms.

Our expertise ensures:

- Precision engineering for consistent panel quality.

- Compliance with international fire protection and insulation standards.

- Cost-effective solutions without compromising durability or performance.

Applications and Industries Served

Shanghe sandwich panels are engineered for versatile use across a wide range of industries. Their thermal insulation, fire resistance, and lightweight construction make them ideal for:

- Industrial buildings and production facilities.

- Cold storage and refrigeration projects requiring precise temperature control.

- Clean rooms and laboratories in pharmaceuticals, electronics, and food sectors.

- Commercial and residential envelopes for energy efficiency.

- Agricultural and livestock facilities with weather-resistant needs.

Why Choose Chinese Sandwich Panels for Global Projects

Choosing Chinese-made sandwich panels can significantly lower material costs while maintaining international quality standards. From material sourcing to production, Chinese manufacturers like Shanghe leverage local supply chain efficiency, allowing us to offer:

- High-quality insulation panels at competitive prices.

- Fast production and delivery for global export.

- Customizable sizes, core materials, and coatings for diverse climates.

- Excellent durability and weather resistance suited to different environments.

- Global compliance with fire safety and insulation regulations.

By combining Chinese manufacturing efficiency with rigorous quality control, Shanghe provides cost-effective, certified, and performance-driven sandwich panel solutions for projects around the world.

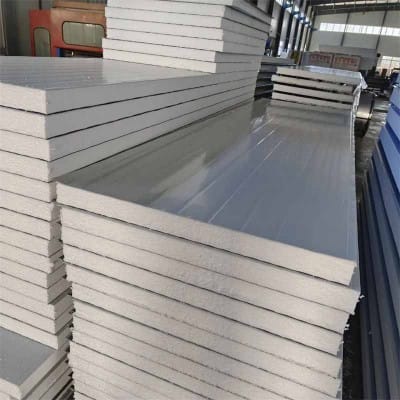

Product Types and Specifications for Sandwich Panel China

We offer a full range of China sandwich insulated panels to suit different building needs. Each type is built for specific performance in thermal insulation, fire resistance, and durability.

PU Polyurethane Sandwich Panels

- Best for: Cold storage, commercial buildings, and industrial facilities needing superior thermal insulation.

- Core: PU (Polyurethane) rigid foam.

- Benefits: Very low thermal conductivity, lightweight, and cost-effective.

- Fire Rating: Class B2/B1 (custom options available).

PIR Polyisocyanurate Sandwich Panels

- Best for: Projects requiring higher fire performance.

- Core: PIR foam with enhanced fire resistance.

- Benefits: Same insulation as PU but with improved flame spread resistance.

- Fire Rating: Class B1 or higher, meeting UL standards.

Rock Wool Sandwich Panels

- Best for: Fire-rated walls and roofs in factories, warehouses, and high-risk areas.

- Core: High-density rock wool.

- Benefits: Non-combustible, top fire resistance, excellent sound insulation.

- Fire Rating: Up to 4 hours fire resistance (ASTM/EN standards).

EPS Expanded Polystyrene Sandwich Panels

- Best for: General purpose walls and roofs with budget-friendly insulation needs.

- Core: EPS foam.

- Benefits: Lightweight, easy to install, cost-efficient.

- Fire Rating: Available in fire-retardant grades.

Standard Panel Specifications

| Specification | PU/PIR Panels | Rock Wool Panels | EPS Panels |

|---|---|---|---|

| Width | 950mm, 1000mm, 1150mm | 950mm, 1000mm | 950mm, 1000mm, 1150mm |

| Length | Up to 12m | Up to 12m | Up to 12m |

| Thickness | 40mm – 200mm | 50mm – 200mm | 40mm – 200mm |

| Density | 38-42 kg/m³ (PU/PIR) | 100-150 kg/m³ | 12-20 kg/m³ |

| Thermal Conductivity | ≤ 0.022 W/m·K (PU/PIR) | ≤ 0.043 W/m·K | ≤ 0.038 W/m·K |

| Fire Resistance | Class B1/B2 (PU/PIR) | Class A (non-combustible) | B2/B3 (custom fire-retardant EPS) |

| Surface Coating | Prepainted galvanized steel (PPGI), Al-Zn coated steel | PPGI or stainless steel | PPGI, aluminum, or stainless steel |

Core Material and Coating Options

- Core Materials: PU, PIR, Rock Wool, EPS.

- Surface Coatings:

- PPGI (Prepainted Galvanized Steel) – Common for roofing/wall cladding.

- Al-Zn Alloy Coated Steel – Better corrosion resistance.

- Stainless Steel – Ideal for clean rooms and hygienic applications.

Technical Parameters

- Thermal Insulation: PU/PIR panels meet high U.S. cold chain requirements, helping reduce energy costs.

- Fire Resistance: Rock wool panels comply with NFPA standards for non-combustibility.

- Soundproofing: Rock wool and PIR options offer excellent noise reduction, up to 30–35dB.

- Weather Resistance: Coated steel skins protect against rust, UV, and moisture.

Features and Benefits of Sandwich Panel China

Our China sandwich insulated panels deliver the performance and durability needed for projects across industrial, commercial, and residential markets in the U.S. Below is a breakdown of the main advantages.

Superior Insulation Performance

- Excellent thermal insulation to keep interiors comfortable year-round

- Reduces energy costs for heating and cooling

- Core materials like PU, PIR, Rock Wool, and EPS tailored for different R-values and climates

- Stable insulation performance — no sagging or moisture damage over time

| Core Material | Thermal Conductivity (W/m·K) | Typical R-Value (per inch) | Best Use Case |

|---|---|---|---|

| PU | 0.020–0.022 | 6.5–7.0 | General building envelopes |

| PIR | 0.018–0.020 | 7.0–7.5 | Cold storage, low-temp facilities |

| Rock Wool | 0.035–0.040 | 3.6–4.0 | Fire-rated walls and roofs |

| EPS | 0.036–0.038 | 3.5–3.9 | Cost-efficient insulation |

High Fire Retardancy Standards

- Fireproof sandwich panels China meet GB, ASTM, and EN standards

- Rock Wool and PIR cores offer Class A / Class 1 fire ratings

- Ideal for projects with strict fire safety requirements

Durability and Weather Resistance

- Steel-faced panels withstand UV, rain, snow, and wind

- Anti-corrosion coating options for long-term use

- Low maintenance — no warping, rotting, or insect damage

Lightweight and Easy Installation

- Up to 40% lighter than solid wall materials

- Pre-fabricated for quick assembly and less labor cost

- Reduces structural load, making it great for retrofits and light structures

Eco Friendly and Sustainable Materials

- CFC-free insulation foams

- Recyclable steel facings

- Meets green building standards to help achieve LEED certification

Cost Effective for Multiple Industries

- Lower material + installation costs compared to traditional brick or concrete

- High insulation reduces long-term energy bills

- Scalable for warehouses, cold storage, barns, clean rooms, and retail spaces

Production and Quality Control of Sandwich Panels China

At Shanghe, we know U.S. customers care about consistent quality, safety, and reliable performance. That’s why our China sandwich insulated panels go through a strict manufacturing and testing process from start to finish.

Advanced Manufacturing Machinery

We operate modern production lines in China equipped with fully automated roll-forming, laminating, and cutting systems. This ensures:

- Precision panel dimensions with minimal tolerance

- Uniform foam injection for core materials like PU, PIR, EPS, and rock wool

- Smooth surface finishes for better joint sealing and aesthetics

- High production speed without compromising quality

Our machinery is sourced from leading equipment suppliers, allowing us to maintain a high output capacity for large-scale and urgent orders, which is ideal for U.S. industrial and construction projects.

Quality Assurance and Certifications

Every Shanghe sandwich panel meets ISO 9001, CE, and SGS standards. For U.S. projects, we can also provide compliance reports aligned with ASTM standards upon request.

- ISO 9001 – International quality management system

- CE marking – European safety and performance compliance

- SGS testing – Independent verification for fire resistance, thermal insulation, and structural integrity

Strict Testing Protocols

Before any shipment leaves our factory, panels are tested for:

- Thermal insulation values (R-value compliance)

- Fire resistance ratings (up to Class A, depending on core material)

- Bending and compressive strength for load-bearing performance

- Surface coating adhesion to prevent peeling and rust

- Dimensional accuracy for seamless on-site installation

We use environmental simulation chambers to check panel performance in extreme heat, cold, humidity, and salt-spray exposure—key for diverse U.S. climates.

Consistent Product Quality Guarantee

Our internal QC team follows a step-by-step inspection process:

- Raw material inspection – Steel coils, insulation cores, and coatings

- In-line monitoring – Automated detection during forming and lamination

- Batch sampling – Panels randomly pulled for lab testing

- Final inspection – Visual check and packaging verification

Because we control every stage of production in-house, Shanghe sandwich panels have uniform density, consistent insulation performance, and reliable structural strength—batch after batch.

Customization Options for Sandwich Panels China

When it comes to sandwich panels from China, every project has its own set of requirements—whether it’s size, thickness, color, or coating. At Shanghe, we provide full customization so the panels you get work perfectly for your build, climate, and design goals.

Custom Sizes and Thickness

We manufacture panels in a wide range of lengths, widths, and thicknesses to match exact specifications. This flexibility helps reduce on-site waste and speeds up installation.

| Parameter | Available Range* | Notes |

|---|---|---|

| Length | Up to 12m (39 ft) | Can be adjusted for transport limits |

| Width | 950mm / 1150mm (standard) | Custom widths available on request |

| Thickness | 40–200mm | Choose for insulation or structural needs |

| Panel Weight | Varies by core material | Optimized for strength and handling |

*Custom beyond standard limits available with MOQ

Color and Surface Coating

We use pre-painted galvanized steel (PPGI), pre-painted galvalume (PPGL), and other finish options to match your building style.

- Over 50 standard RAL colors available

- Anti-fade and anti-corrosion coatings for long-term performance

- Food-grade coating options for cold storage or clean room use

Climate-Specific Solutions

Panels can be engineered for:

- High heat zones – better UV resistance and thermal protection

- Cold climates – improved insulation to reduce heat loss

- Coastal/marine areas – enhanced anti-corrosion coating systems

- High wind zones – reinforced panel profiles for stability

OEM and Branding Support

If you’re a contractor, retailer, or brand, we can provide:

- OEM production with your specifications

- Logo printing and branded packaging

- Custom labeling for project identification

- Private mold development for unique designs

This level of flexibility allows U.S. builders, distributors, and project planners to get ready-to-install panels that meet both local building code demands and aesthetic preferences, while benefiting from the pricing and capacity advantages of a reliable Chinese sandwich panel manufacturer.

Applications of Sandwich Panels in China and the US Market

Industrial Buildings and Warehouses

Shanghe sandwich panels from China are widely used for constructing factory facilities, logistics hubs, and storage warehouses. The panels provide strong structural support, high insulation, and quick installation, making them ideal for both new builds and retrofits. Their fireproof and corrosion-resistant properties ensure long-term durability, even in demanding industrial environments.

Key benefits for industrial use:

- Reduce energy costs through excellent thermal insulation.

- Withstand heavy usage and harsh weather conditions.

- Speed up construction time to keep operations on schedule.

Cold Storage and Refrigeration Facilities

For temperature-controlled storage, Shanghe PU, PIR, and EPS sandwich panels offer superior thermal performance and minimal thermal bridging. This makes them perfect for food processing plants, cold rooms, refrigerated warehouses, and pharmaceutical storage.

Advantages for refrigeration:

- Maintain consistent internal temperatures.

- Reduce energy loss and operational costs.

- Meet international hygiene and safety standards.

Clean Rooms and Laboratories

In controlled environments like clean rooms, research labs, and medical manufacturing plants, our rock wool and PIR sandwich panels provide excellent fire resistance, noise control, and dust-free performance. Specific coating options also help meet sterile surface requirements.

Usage benefits:

- Easy-to-clean, hygienic surfaces.

- Compliance with ISO clean room standards.

- Custom finishes to suit high-spec industries like electronics, pharmaceuticals, and biotech.

Commercial and Residential Building Envelopes

Shanghe steel sandwich panels are a great choice for commercial complexes, offices, retail stores, and modern residential housing. The panels offer excellent insulation, stylish exterior options, and a wide color range, helping developers achieve both functionality and design goals.

Highlights:

- Lower heating and cooling costs year-round.

- Fast build times for real estate projects.

- Long-lasting, low-maintenance exterior cladding.

Agricultural and Animal Husbandry Buildings

In agricultural settings like barns, poultry houses, and crop storage facilities, our Chinese insulation sandwich panels protect against temperature extremes, moisture, and pest issues.

Benefits for the agricultural sector:

- Maintain animal comfort and crop quality.

- Easy to clean and sanitize.

- Weatherproof and resistant to corrosion.

Why Buy Sandwich Panel China

When you source sandwich panels from China, choosing the right manufacturer makes all the difference. At Shanghe, we’ve built a solid reputation by combining 20 years of manufacturing expertise, strong quality control, and efficient supply chain management tailored for the global market — including the U.S. construction industry.

20 Years of Manufacturing Experience

We’ve been producing PU, PIR, EPS, and rock wool sandwich panels in China for two decades. This experience means we understand different project needs — from industrial cold storage to commercial building envelopes — and deliver panels that meet strict U.S. and international standards.

Competitive Pricing with No Quality Compromise

Our local raw material sourcing and optimized production lines keep costs low without cutting corners. We consistently supply cost-effective panels to wholesalers, contractors, and prefab builders in the U.S. looking for high value per square foot.

Fast Production and Reliable Delivery

Thanks to our automated production lines and efficient Chinese supply chain, we can meet tight schedules for both small and bulk orders. Whether it’s standard sizes or custom dimensions, our lead times are designed to support your construction timelines.

Typical Production and Delivery Timeline:

- Small orders: 7–10 days production + shipping

- Bulk orders: 15–20 days production + shipping

- Flexible shipping options by sea or express air freight

Strong Export Experience and Global Client Base

We’ve shipped to over 60 countries, with a proven record of handling export documentation, customs clearance, and international logistics. U.S. clients benefit from simplified paperwork and dependable delivery tracking.

Dedicated After-Sales Support

Our service doesn’t end with delivery:

- Technical guidance for installation

- Panel maintenance tips to extend lifespan

- Warranty coverage for manufacturing defects

- Quick replacement policy for approved claims

Key Advantages of Shanghe as Your China Sandwich Panel Supplier:

- Two decades of proven manufacturing in China

- Factory-direct pricing with no middleman markups

- Flexible production for different climates and building codes

- Professional export handling for U.S. projects of all sizes

- Dedicated English-speaking sales and support team

Frequently Asked Questions about Sandwich Panels from China

What Makes Chinese Sandwich Panels Different

Chinese sandwich panels, especially from established manufacturers like Shanghe, stand out because of competitive production efficiency, advanced machinery, and strict quality control. With over 20 years in the industry, we’ve combined international-grade thermal insulation, fire safety ratings, and robust weather resistance at a lower cost due to optimized supply chains. This means you get top-tier PU, PIR, EPS, and Rock Wool panels at a price point that’s hard to match globally.

Can Panels Be Shipped Internationally

Yes. We regularly export sandwich panels across the US and other global markets. Panels are packed securely for sea freight or containerized transport to avoid damage during long-distance shipping. We handle export documentation, customs requirements, and loading safety, so there’s no extra hassle for you.

Lead Time for Bulk Orders

Lead time depends on panel type, quantity, and customization requirements:

- Standard stock panels – typically ready in 7-10 days

- Custom-size, color, or coating orders – usually 14-20 days

- Large export shipments – allow extra 5-10 days for shipping and customs clearance

We also offer fast-track production for urgent projects if the timeline is critical.

How to Maintain Sandwich Panels

Proper maintenance helps extend the life of your panels:

- Inspect joints and seals every 6-12 months

- Clean with mild soap and water — avoid abrasive cleaners

- Check for dents or coating damage and repair promptly to avoid rust or moisture ingress

- Ensure proper drainage in panel areas to prevent water pooling

- Avoid excessive loading or impact on panel surfaces

These steps keep insulation performance and appearance at their best.

Warranty and Support Details

Shanghe sandwich panels come with a standard product warranty covering:

- Structural integrity for up to 10 years

- Thermal insulation performance within rated values

- Surface coating durability against corrosion and fading

We provide technical support, on-site consultation (when possible), spare parts supply, and post-sales service for our US customers. For specific warranty terms on PU, PIR, EPS, or Rock Wool panels, contact us directly.

Contact and Inquiry for Sandwich Panel China

Direct Consultation with Our Experts

If you need product consultation on sandwich panels from China, we have a dedicated team ready to assist. Whether you are looking for PU, PIR, EPS, or rock wool sandwich panels, we can help you choose the right type, thickness, and specifications for your project in the United States.

- Get accurate advice for industrial, commercial, residential, or cold storage applications.

- We explain technical details in simple terms so you know exactly what you are buying.

- Direct communication with our factory engineering team for custom design requests.

Request a Quote

We make it easy to get a price for your order of Chinese insulation sandwich panels.

Here’s what you need to provide for a fast, accurate quote:

- Panel type (PU, PIR, EPS, or rock wool)

- Panel dimensions (length, width, thickness)

- Quantity required

- Shipping destination (we handle port-to-door shipping to the US)

- Any custom colors or surface finishes you prefer

Once we receive this information, our sales team will send you a detailed quotation including unit cost, shipping options, and lead times. We also provide comparison options so you can make the right choice for your budget.

Arrange a Factory Visit

We welcome US-based customers to visit our sandwich panel manufacturing facility in China:

- See our production line, quality control testing, and material storage firsthand.

- Discuss project requirements directly with our technical and production managers.

- Review sample panels for fit, finish, and performance testing before placing bulk orders.

Sample Orders for US Customers

If you want to test the quality before a big purchase, we can ship samples to your location in the USA.

- Samples available in different core materials and panel thicknesses.

- We include technical datasheets and performance certificates (ISO, CE, SGS).

Contact us today for professional assistance, quick pricing, and reliable export of China-made sandwich insulated panels to the United States. We respond within 24 hours to all inquiries.

Related Products and Resources for Sandwich Panels China

We offer a full range of Chinese insulation sandwich panels and related resources so you can choose the right material for your project. Every option comes with technical documentation, performance data, and real-world use cases so you can make an informed decision.

Other Insulation Panel Options

Alongside our PU, PIR, Rock Wool, and EPS panels, we also supply:

- Steel sandwich panels China – strong exterior and impact-resistant core.

- Fireproof sandwich panels China – designed to meet strict U.S. and international fire safety standards.

- China prefab sandwich panels – pre-cut for fast installation in modular builds.

- Cold storage insulation panels – high thermal retention for refrigeration and freezers.

Technical Datasheets and Brochures

For every product, you can get detailed technical datasheets including:

| Available Thickness | 40mm – 200mm |

| Core Options | PU, PIR, Rock Wool, EPS |

| Panel Width | 950mm – 1200mm |

| Surface Coating | Color-coated steel, galvanized steel, stainless steel |

| Thermal Conductivity | As low as 0.018 W/m·K (PU and PIR cores) |

| Fire Ratings | Up to EI 120 (Rock Wool core) |

| Density Range | 40–150 kg/m³ (material dependent) |

All datasheets are downloadable in PDF format for easy reference and planning.

Case Studies and Performance Results

See how other sandwich panel manufacturers in China have delivered for clients worldwide. Our case studies cover:

- Industrial warehouses built with PU and PIR panels in extreme climates.

- Cold storage facilities maintaining steady sub-zero temperatures with energy savings.

- Agricultural buildings using Rock Wool panels for fire safety in high-risk areas.

- Commercial projects using EPS panels for cost-effective construction without losing insulation efficiency.

Customer Testimonials

We share real feedback from U.S. contractors, builders, and distributors who have used our products:

- “We imported PU sandwich panels from China for a cold storage build in Texas — panels arrived on time, quality was excellent, and performance exceeded our expectations.”

- “The Rock Wool sandwich panels met U.S. fire rating requirements with no issues. Installation was faster than expected.”

Downloadable Resources

You can request or download:

- Full product catalogs with images and specifications

- Performance test reports for thermal and fire resistance

- Installation guides for DIY and professional crews

- OEM branding templates for custom manufacturing