What Are sandwich panel corrugated sheet

If you’re wondering what exactly a corrugated sandwich panel is, you’re not alone. These panels are a smart solution used widely in construction for roofing, walls, and insulation. Simply put, a sandwich panel corrugated sheet consists of three layers: two outer metal sheets with a corrugated core in the middle.

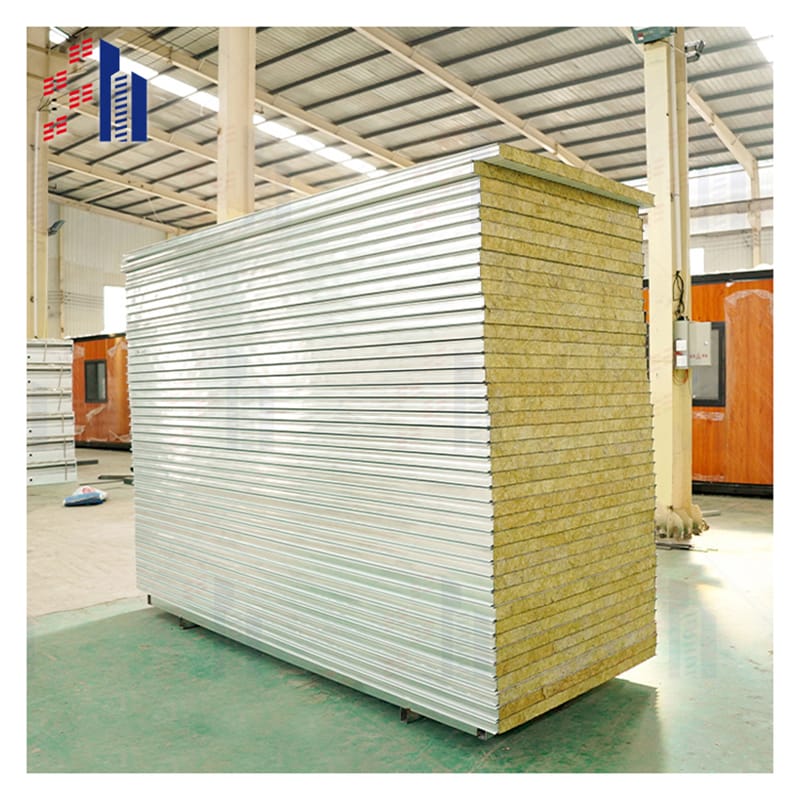

Structure

The panel’s outer layers are usually made from durable sandwich panel corrugated sheet, known for their strength and weather resistance. Sandwiched between these is a core that’s often made of insulation materials like foam or mineral wool. The core can be flat or corrugated, adding to the panel’s rigidity and strength without increasing weight.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Corrugation Benefits

Why is the corrugated core so important? It provides:

- Increased strength and the ability to carry heavier loads

- Better impact resistance compared to flat layers

- Enhanced rigidity which helps panels resist bending or buckling

- Improved ventilation and drainage when used on roofing

These benefits make corrugated core sandwich panels ideal for projects needing durable, lightweight construction solutions.

Types of Corrugated Sandwich Panels

There are several types based on core materials and corrugation patterns:

- Polyurethane or PIR insulated panels for excellent thermal performance

- Mineral wool cores for fire resistance and sound insulation

- Metal corrugated cores for extra structural strength

Each type caters to specific needs, whether it’s thermal insulation, fire safety, or load-bearing capacity.

Comparison

Compared to traditional flat sandwich panels, corrugated sandwich panels stand out because they:

- Offer a better strength-to-weight ratio

- Deliver more durability under harsh weather conditions

- Provide superior thermal and acoustic insulation when using the right core materials

In short, corrugated sandwich panels are versatile, strong, and efficient, making them a preferred choice for many building applications.

If you’re interested in a solution that balances strength, insulation, and cost-efficiency, these panels might be exactly what your project needs.

Key Benefits of Shanghe’s Corrugated Sandwich Panels

Shanghe’s corrugated sandwich panels stand out for their impressive strength to weight ratio. These panels provide solid structural support without adding extra bulk, making them ideal for lightweight construction projects where every pound counts.

When it comes to thermal and acoustic insulation, our insulated sandwich panels excel at keeping buildings comfortable. They help maintain indoor temperatures and reduce noise pollution, which is a big plus for both homes and commercial spaces here in the U.S.

Fire resistance is another major benefit. Shanghe’s panels meet strict U.S. safety standards, giving you peace of mind that your building materials can withstand higher temperatures and help slow down fire spread.

Durability is built-in with these panels. Thanks to the corrugated metal sheet design and high-quality materials, they resist weather damage, corrosion, and wear, ensuring a long-lasting solution for your construction needs.

Finally, Shanghe’s corrugated sandwich panels offer excellent cost efficiency. Their easy installation, low maintenance, and energy-saving features help cut down on both upfront and ongoing expenses, making them a smart investment for U.S. builders and property owners.

Applications of Corrugated Sandwich Panels

Corrugated sandwich panels are versatile and widely used across different types of construction in the U.S. Here’s where they make a difference:

Industrial Buildings

These panels are a top choice for warehouses, factories, and manufacturing plants. Their strength, fire resistance, and thermal insulation help protect sensitive equipment and keep energy costs down.

Commercial Structures

From office buildings to shopping centers, corrugated sandwich panels provide a sleek look while offering durability and sound insulation, making workplaces more comfortable and cost-effective to maintain.

Residential Projects

Homeowners and builders use insulated sandwich panels for modern homes, garages, and home offices. They’re lightweight and easy to install, offer great thermal insulation, and help keep energy bills low.

Specialized Uses

Beyond typical buildings, these panels are popular for refrigerated storage, clean rooms, and modular construction. Their ability to maintain temperature control and resist fire makes them perfect for specialized needs.

Local Case Studies

In the United States, we’ve seen these panels perform exceptionally well in places like Texas warehouses needing heat resistance, California commercial interiors focusing on energy efficiency, and Midwestern homes installed for quick build times and insulation value. These real-world examples highlight their adaptability to different climates and project types.

Corrugated sandwich panels blend lightweight construction with solid performance, making them a smart choice for many building projects right here in the U.S.

Why Choose Shanghe’s Corrugated Sandwich Panels

Quality Manufacturing

Shanghe stands out for its top-notch quality in producing corrugated sandwich panels. Every panel undergoes strict quality checks to ensure durability, consistent performance, and compliance with industry standards. This means you get reliable insulated sandwich panels that hold up well, no matter the weather or application.

Customization

We understand that every project is different. That’s why Shanghe offers customizable options for corrugated core sandwich panels—whether you need specific sizes, thicknesses, or insulation types. This flexibility lets you tailor panels to fit your exact needs, making your construction process easier and more efficient.

Local Availability

Shanghe’s corrugated sandwich panels are readily available across the United States, ensuring quick delivery and easy access when you need them. Having local stock reduces wait times and shipping costs, which can be a big advantage for your project schedule and budget.

Sustainability

We’re committed to environmentally responsible manufacturing. Shanghe uses eco-friendly materials and processes that reduce waste and energy consumption. Choosing our fire resistant sandwich panels means you’re also supporting sustainable building practices that align with green construction standards common in the US market.

Customer Support

Good support matters, especially when handling technical products. Shanghe offers expert customer service to guide you through product selection, installation questions, and after-sales care. Our team is ready to help you make the best choices for your building needs, ensuring a smooth experience from start to finish.

Technical Specifications and Installation

Specifications

Shanghe’s sandwich panel corrugated sheet features a corrugated metal core sandwiched between durable outer layers, offering excellent strength to weight ratio. These insulated sandwich panels come in various thicknesses and sizes to suit different project needs. Each panel provides effective thermal insulation and fire resistance, meeting the US building codes for safety and energy efficiency. Panels are lightweight yet sturdy, making handling and installation easier on-site.

Installation Guide

Installing Shanghe corrugated sandwich panels is straightforward:

- Start with a clean, level surface for the structure’s frame.

- Fasten panels securely with recommended screws and sealing materials to prevent air and water leaks.

- Overlap joints at corrugated edges ensure weather-tightness.

- Follow manufacturer guidelines for panel orientation and spacing to maximize thermal and acoustic performance.

- Use insulated sandwich panel accessories like trims and flashings for a clean finish.

Compliance

Our corrugated sandwich panels comply with local and national building standards, including fire safety regulations and energy efficiency requirements. We ensure all products meet ASTM and ICC codes commonly used throughout the United States. This guarantees you get panels that are safe, reliable, and suitable for industrial, commercial, and residential applications.

If you need detailed specs or installation support, Shanghe’s team is ready to assist with everything local builders need.

How to Purchase Shanghe Corrugated Sandwich Panels

Ordering Process

Getting your hands on Shanghe corrugated sandwich panels is straightforward. You can start by visiting our website or contacting our local sales team. Simply provide your project details, such as panel size, type, and quantity, and we’ll guide you through the options. We aim to make the entire ordering process smooth, from price quotes to delivery schedules.

Pricing Factors

Several factors influence the cost of corrugated sandwich panels, including:

- Panel thickness and material (insulated sandwich panel or basic corrugated metal sheet)

- Type of core and corrugation style

- Quantity ordered (bulk orders often get better pricing)

- Custom features like fire resistance or special coatings

- Delivery location and shipping costs within the U.S.

Rest assured, we provide competitive pricing designed to fit local U.S. construction budgets.