PIR Foam Sandwich Panels Composition and Manufacturing Key Properties

Polyisocyanurate (PIR) Sandwich Panel Pir Foam are high-performance building materials widely used for insulation and structural applications. These panels consist of a rigid PIR foam core laminated between two outer facings, typically made of galvanized steel or aluminum. This composition delivers exceptional thermal efficiency, strength, and fire resistance – key attributes for modern construction demands.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

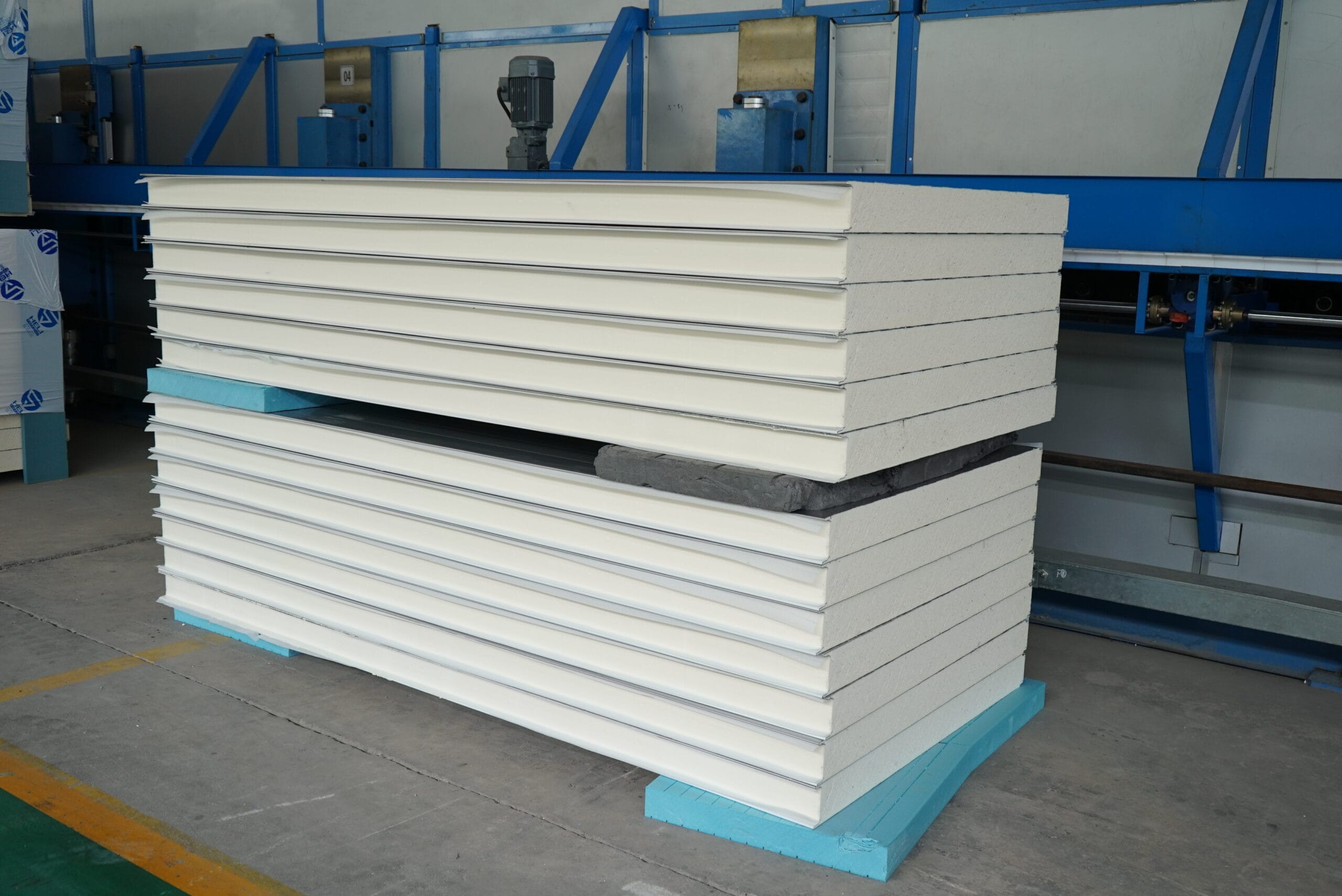

Composition and Manufacturing

- Core Material: The heart of the panel is PIR foam, a closed-cell thermoset insulation that outperforms traditional polyurethane (PUR) and expanded polystyrene (EPS) foams. PIR foam is chemically enhanced with a higher isocyanurate content, which grants superior thermal stability and fire resistance.

- Facings: Usually metal sheets such as galvanized steel or aluminum provide structural integrity, weather resistance, and durability. Occasionally, specialized coatings or colors are applied for additional corrosion resistance and aesthetic preferences.

- Manufacturing Process: The panels are produced via continuous lamination where the PIR foam is foamed in place or injected between facings, then cured under controlled pressure and temperature. This produces a uniform core-to-facer bond ensuring consistent insulation performance and mechanical strength.

Key Properties

- Thermal Conductivity: PIR foam panels boast a low thermal conductivity rate, typically 0.022 to 0.026 W/m·K, delivering superior insulation that significantly reduces heating and cooling costs.

- Fire Resistance: Unlike many insulation materials, PIR foam is naturally fire-retardant, self-extinguishing, and complies with stringent fire rating standards such as ASTM E84 Class A or comparable UL tests.

- Mechanical Strength: The sandwich structure offers high compressive strength, load-bearing capacity, and resistance to impact, making PIR panels ideal for roofs, walls, and cold storage facilities.

- Moisture Resistance: The closed-cell nature of PIR foam prevents water absorption, minimizing risks of mold and structural degradation over time.

- Lightweight Profile: Despite their strength, PIR sandwich panels are lightweight, simplifying handling and installation without compromising durability.

Shanghe’s PIR foam sandwich panels combine advanced materials and precision manufacturing to provide an insulation solution that balances energy efficiency, fire safety, and longevity. These attributes make them a reliable choice for architects, builders, and project managers aiming to meet high-performance building standards in today’s competitive construction market.

Benefits of Shanghe PIR Foam Sandwich Panels

Shanghe PIR foam sandwich panels offer several advantages that make them a top choice for building and insulation projects in the U.S. market. These panels combine excellent thermal performance, superior fire resistance, and strong durability, all while supporting sustainable construction practices.

Energy Efficiency

One of the standout benefits of Shanghe PIR foam sandwich panels is their low thermal conductivity, which delivers outstanding insulation. With a polyisocyanurate (PIR) foam core, these panels help maintain indoor temperatures efficiently, cutting down on energy costs for cooling and heating. This makes them ideal for:

- Energy-efficient building materials requirements

- Cold storage facilities where temperature control is critical

- Industrial and commercial buildings aiming to reduce energy consumption

Their strong insulation means your building stays comfortable year-round without extra load on HVAC systems.

Fire Safety

Safety is a key concern in construction, and Shanghe PIR sandwich panels are engineered for fire resistance. Unlike standard foam insulation panels like EPS, PIR foam has better fire-retardant properties and complies with strict fire ratings demanded in U.S. building codes. Benefits include:

- Slower flame spread compared to PUR or EPS panels

- Lower smoke generation during a fire

- Suitability for commercial and multi-family residential construction where fire safety is critical

This makes Shanghe panels a trustworthy option for projects requiring fire-resistant sandwich panels.

Durability and Versatility

These panels are designed to withstand tough conditions without losing their insulating ability or structural integrity. They are:

- Resistant to moisture and chemical exposure

- Stable under temperature fluctuations

- Lightweight, which makes installation easier and reduces structural load

- Suitable for roofing, wall cladding, and cold storage insulation

Their flexibility means you can use them across industrial construction panels, residential, and specialty applications.

Sustainability

With growing demand for green building materials, Shanghe PIR foam panels support sustainability goals by offering:

- Long lifespan with minimal maintenance

- Reduced energy demand helps lower carbon footprint

- Use of recyclable materials in manufacturing processes

- Compliance with sustainable construction materials standards in the U.S.

Choosing these panels can help you achieve energy efficiency goals while keeping environmental impact low.

By choosing Shanghe PIR foam sandwich panels, you get a product that blends energy efficiency, fire safety, durability, and sustainability—making it an excellent fit for the evolving needs of the American construction market.

Applications of Shanghe PIR Foam Sandwich Panels

Shanghe PIR foam sandwich panels are designed to meet the diverse needs of the U.S. market with excellent performance across several sectors. Their superior insulation and fire-resistant properties make them a go-to choice for various applications.

Industrial and Commercial Use

In industrial and commercial construction, Shanghe PIR sandwich panels provide reliable thermal insulation and structural strength. They’re widely used for:

- Warehouses and factories where temperature control and energy efficiency are crucial.

- Office buildings requiring lightweight, durable, and energy-efficient wall and roofing solutions.

- Clean rooms and manufacturing plants that demand strict temperature and fire safety standards.

Their low thermal conductivity ensures reduced energy costs and a comfortable indoor environment.

Cold Storage Facilities

Cold storage demands highly effective insulation panels, and Shanghe PIR foam sandwich panels excel here. They help maintain precise temperature control with:

- Minimal heat transfer due to polyisocyanurate foam core.

- Excellent moisture resistance, preventing condensation and frost buildup.

- Compliant fire safety ratings required by food and pharmaceutical cold storage regulations.

This makes them ideal for refrigerated warehouses, food processing plants, and distribution centers focusing on keeping goods fresh and safe.

Residential Construction

For residential projects, Shanghe PIR panels offer:

- Energy-efficient walls and roofs that keep heating and cooling costs low.

- Enhanced fire resistance for improved home safety.

- Lightweight design enabling easier installation and renovation.

Whether for new home builds or energy-efficient retrofits, these panels provide a smart balance of comfort, safety, and savings.

Specialty Uses

Beyond standard applications, Shanghe PIR foam sandwich panels support specialty projects, thanks to their customizable nature:

- Cleanrooms and laboratories needing controlled environments.

- Agricultural buildings requiring temperature and moisture control.

- Modular construction for fast, flexible building solutions.

Their versatility, combined with Shanghe’s customization options, makes them fit for niche markets that insist on performance and reliability.

Interested in exploring other panel types? Check out our fiberglass sandwich panels or metal sandwich panels for more construction solutions.

Comparing PIR vs PUR and EPS Sandwich Panels

When choosing insulation for your project, understanding the differences between PIR foam sandwich panels, PUR (polyurethane), and EPS (expanded polystyrene) panels is key. Here’s a quick and clear comparison to help you decide why Shanghe PIR foam sandwich panels are a smart choice for construction in the U.S. market.

PIR vs PUR Sandwich Panels

- Thermal Performance: PIR panels provide better thermal insulation than PUR. With a lower thermal conductivity (around 0.021 W/m·K for PIR compared to about 0.025 W/m·K for PUR), PIR keeps buildings warmer or cooler more efficiently, reducing energy bills.

- Fire Resistance: PIR panels have a higher fire rating due to their chemical structure, making them more fire-resistant than PUR. This is a huge safety plus for commercial and industrial buildings.

- Durability: PIR foam has better dimensional stability and resists moisture more effectively, meaning it won’t break down or lose effectiveness over time like some PUR panels can.

- Cost: PUR panels are typically less expensive but may require trade-offs in fire safety and durability.

PIR vs EPS Sandwich Panels

- Insulation Quality: PIR panels outperform EPS in insulation. EPS has a thermal conductivity around 0.035 W/m·K, which is significantly higher than PIR’s. This means PIR offers better energy efficiency in less thickness.

- Fire Behavior: EPS is combustible and requires extra fire-retardant measures. PIR panels are naturally fire-resistant, offering enhanced safety without extra coatings.

- Moisture Resistance: PIR foam is closed-cell, making it highly resistant to water absorption. EPS can absorb moisture over time, reducing its insulation value.

- Weight and Strength: PIR panels are lightweight yet strong, suited for roofing and wall applications requiring durability. EPS is lighter but less mechanically robust.

Why Shanghe PIR Foam Sandwich Panels Stand Out

- Superior Thermal Insulation: Shanghe PIR panels feature optimized foam density delivering exceptionally low thermal conductivity. Ideal for energy-efficient building projects across the U.S.

- Enhanced Fire Safety: With strict compliance to U.S. building codes, Shanghe PIR panels offer enhanced fire resistance, helping protect from fire hazards in commercial and residential uses.

- Moisture and Durability Advantages: The closed-cell PIR foam core ensures excellent moisture resistance and long-term durability, even in humid or variable climates.

- Customization and Quality Control: Shanghe provides panels in various thicknesses and facing materials, tailored to the specific needs of your project. Rigorous quality checks guarantee consistent performance.

- Competitive Pricing: While delivering premium PIR panel properties, Shanghe keeps pricing competitive, offering great value compared to other international brands.

Choosing Shanghe PIR sandwich panel insulation means getting the best mix of energy efficiency, fire safety, and durability, built for the demands of American industrial, commercial, and residential construction.

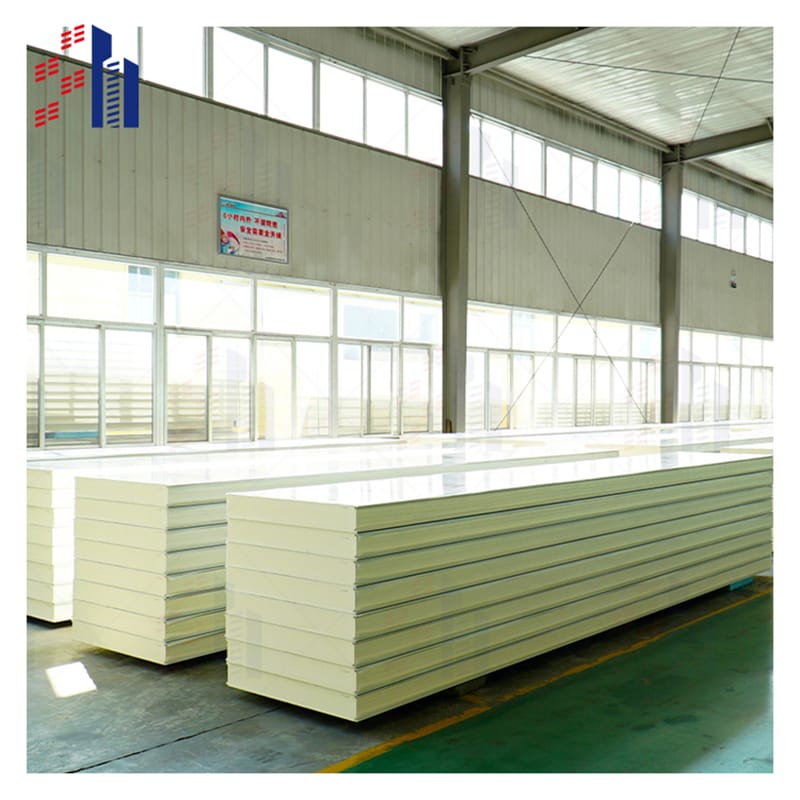

Installation and Customization of Shanghe PIR Foam Sandwich Panels

Easy Installation for Fast Project Completion

Shanghe PIR foam sandwich panels are designed with installation ease in mind, making them a popular choice for U.S. builders focused on efficiency. The panels come with lightweight construction and precise tongue-and-groove edges, which allow for tight, seamless fitting without complicated tools. This design helps reduce labor time and costs on-site.

Key installation features include:

- Pre-cut sizes and consistent thickness, simplifying alignment

- Lightweight panels that are easy to handle, even in tight spaces

- Compatible with standard fasteners and structural supports

- Minimal preparation required, ideal for roofing, wall cladding, and cold storage setups

Customization Options Tailored for Your Needs

Shanghe offers a wide range of customization possibilities to meet specific project requirements across industrial, commercial, and residential sectors. These options let you get the most out of your energy-efficient PIR sandwich panel insulation by matching the panel specs perfectly to your application.

Customization benefits include:

- Variable panel thicknesses, typically ranging from 1 to 6 inches, for different insulation levels

- Choice of face materials, including galvanized steel, aluminum, or coated surfaces suited for weather resistance and aesthetics

- Fire-resistant coatings and enhanced PIR foam formulations for higher fire ratings in compliance with U.S. building codes

- Cut-to-size panels and various lengths to minimize waste and installation time

- Options for integrated vapor barriers to improve moisture control in cold storage or humid environments

With these features, Shanghe PIR foam sandwich panels provide flexibility while ensuring consistent quality and performance for your construction project.

By focusing on easy installation and versatile customization, Shanghe PIR panels adapt well to your project’s unique demands — helping you build smarter with energy-saving, fire-resistant, and durable materials.

Market Trends and Growth Opportunities for PIR Foam Sandwich Panels

Rising Demand for PIR Foam Sandwich Panels

The demand for sandwich panel PIR foam is steadily growing across the United States, driven by increasing energy efficiency standards and stricter fire safety regulations. Builders and developers are moving toward energy-efficient building materials that reduce heating and cooling costs while maintaining safety. Polyisocyanurate (PIR) foam panels, known for their excellent thermal conductivity and high fire resistance, fit perfectly into this trend.

Key factors fueling demand include:

- Growing construction in industrial and commercial sectors

- Expansion of cold storage facilities due to rising food and pharmaceutical needs

- Interest in sustainable and lightweight roofing panels

Regional Insights Across the United States

Certain regions show particularly strong growth potential for PIR foam sandwich panels based on climate and construction activity:

- Northern states and colder regions prioritize thermal performance and rely heavily on insulated panels to cut energy costs.

- Urban areas with strict fire codes prefer fire-resistant sandwich panels, making PIR panels a top choice.

- Southeastern regions are adopting these panels for their durability against humidity and weather extremes.

This geographic diversity confirms that PIR foam panels are versatile and meet a variety of local building requirements and climate challenges.

Shanghe’s Role in Market Growth

Shanghe is playing a significant role in advancing the market for PIR sandwich panel insulation by focusing on:

- Providing high-quality PIR foam panels that meet U.S. construction standards

- Offering custom solutions tailored to specific regional needs and project specs

- Supporting builders with detailed product information and technical support to ease installation and compliance

- Competitive pricing that makes PIR foam sandwich panels accessible across different market segments

By combining innovation, quality control, and customer support, Shanghe is positioned to lead growth and help customers capitalize on the rising trend toward safer, more energy-efficient building materials in the U.S. market.

Why Choose Shanghe PIR Foam Sandwich Panels Quality Assurance Customer Support Competitive Pricing

When it comes to selecting sandwich panel PIR foam for construction projects in the United States, Shanghe stands out for several key reasons. We understand that building professionals and property owners need reliable, high-performance materials that deliver value without compromise. Here’s why Shanghe’s PIR foam sandwich panels are the right choice.

Quality Assurance for Reliable Performance

Shanghe’s polyisocyanurate foam panels are manufactured under strict quality controls to meet and exceed industry standards. Each panel offers:

- Consistent thermal conductivity PIR foam, ensuring excellent insulation and energy-saving benefits

- Superior fire-resistant sandwich panel qualities, tested to meet U.S. fire safety codes

- Durable facings and core that resist wear, moisture, and deformation over time

- Certifications and compliance with international standards, supporting safe, sustainable construction

This focus on quality means when you choose Shanghe, you get products made for long-lasting, trouble-free performance in industrial, commercial, or residential settings.

Dedicated Customer Support Tailored to Your Needs

Shanghe goes beyond just supplying panels. We provide reliable, knowledgeable customer support aimed at helping you:

- Select the right PIR sandwich panel specification for your specific project needs

- Answer questions about installation and customization options

- Ensure smooth logistics and timely delivery — no unexpected delays on site

- Access technical guidance to maximize the benefits of your energy-efficient building materials

Our responsive team is committed to making your project easier from start to finish.

Competitive Pricing Without Compromising Quality

In a competitive market, Shanghe offers smart pricing on sandwich panel PIR foam that balances cost-efficiency with premium quality. This means you can invest in:

- High-performance insulation that reduces energy bills over time

- Materials that decrease maintenance and replacement costs thanks to their durability

- A partner who understands local market demands and delivers value-driven solutions

Choosing Shanghe gives you access to industrial construction panels and other formats geared to fit within your budget while supporting sustainable, efficient building practices.

By combining quality assurance, strong customer support, and fair pricing, Shanghe PIR foam sandwich panels provide a reliable, cost-effective solution that meets the growing demand for fire-resistant and energy-efficient sandwich panels in the U.S. market.

FAQs about Sandwich Panel PIR Foam

What is a PIR foam sandwich panel

PIR (Polyisocyanurate) foam sandwich panels consist of rigid PIR foam insulation core sandwiched between two outer metal or composite facings. This construction offers excellent thermal insulation, fire resistance, and structural strength, making it ideal for energy-efficient building projects.

How does PIR compare to other foam sandwich panels

Compared to PUR (Polyurethane) and EPS (Expanded Polystyrene) foam panels, PIR panels have:

- Better fire performance due to higher fire resistance and slower burning rate

- Improved thermal conductivity, offering superior insulation at thinner thicknesses

- Enhanced durability in harsh environments

What are the typical PIR sandwich panel specifications

Common PIR foam sandwich panel specs include:

- Thicknesses ranging from 40 mm to 120 mm depending on insulation needs

- Core density around 40-45 kg/m³ for optimal strength and thermal resistance

- Facings made from galvanized steel, aluminum, or other composite materials for durability

- Fire ratings typically meeting Class A or B standards for US building codes

Where can PIR foam sandwich panels be used

PIR panels work well in:

- Industrial and commercial buildings

- Cold storage and refrigerated warehouses

- Residential roofing and walls

- Specialty uses like clean rooms and food processing plants

Is installation of Shanghe PIR sandwich panels easy

Yes. These panels are designed for quick, efficient installation with lightweight properties and easy fixing options. Custom sizing and facing options are also available to fit specific project needs.

Are Shanghe PIR panels eco-friendly

Absolutely. PIR foam sandwich panels from Shanghe are made with sustainable materials that lower energy consumption during use and reduce carbon footprints. Their excellent insulation helps cut heating and cooling costs significantly.

Where can I find detailed product options

Explore a variety of PIR foam sandwich panels, including thicknesses and facing materials, at Shanghe’s product range here:

How does pricing compare for PIR foam sandwich panels

PIR panels may have a slightly higher upfront cost compared to EPS but provide better long-term savings through energy efficiency and durability. Shanghe offers competitive pricing with consistent quality, making PIR panels a cost-effective choice for US construction projects.

For more detailed specifications and installation guides, feel free to contact our support team or visit the Shanghe website.