Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

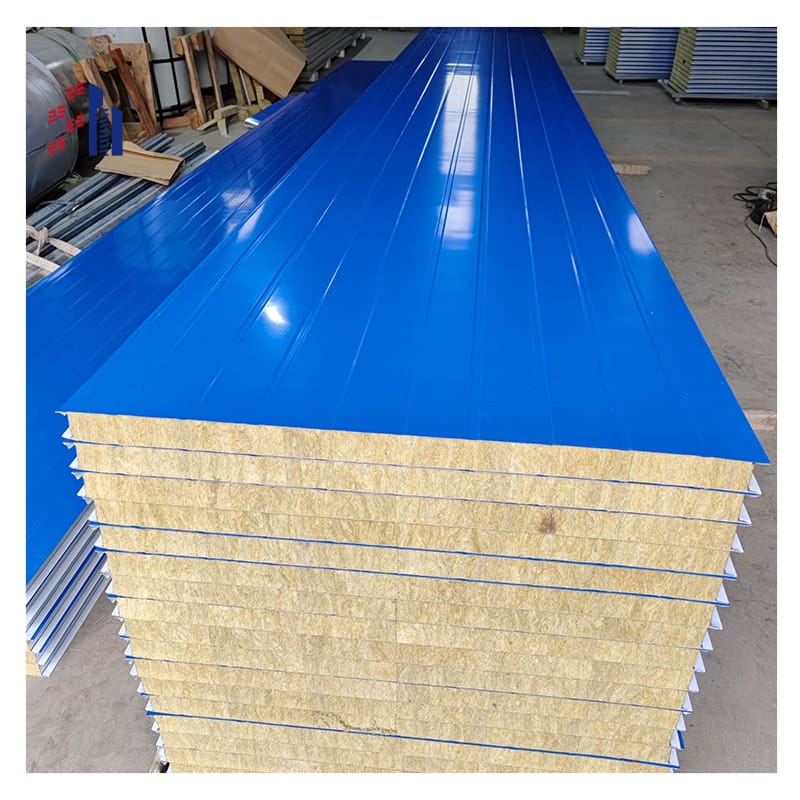

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why PVC Foam Sandwich Panels Are Outperforming Traditional Materials in 2025

Let me tell you something most suppliers won’t—if you’re still using steel or aluminum sandwich panels, you’re missing out on the PVC foam sandwich panel revolution. These lightweight yet ultra-durable panels are taking over projects from Leroy Merlin’s retail stores to Amazon’s latest warehouses, and for good reason.

The Problem:

Traditional panels are heavy, requiring costly structural support.

Poor moisture resistance leads to mold and corrosion.

Limited design flexibility (ever tried painting a metal panel without it chipping?).

The Solution:

PVC foam cores are 30% lighter than steel, cutting foundation costs.

100% waterproof (used in marine applications by the US Navy).

Easy to cut and shape on-site, saving time and labor.

Real-World Proof:

Bottom Line: If you want faster, cheaper, and more sustainable builds, PVC foam sandwich panels are the way to go.

PVC XPS Sandwich Panel: The Secret to Energy-Efficient Buildings

Think insulation is just about R-values? Think again. PVC XPS sandwich panels combine closed-cell foam cores (that’s the XPS part) with rigid PVC skins, creating a thermal barrier that outperforms fiberglass by 3-to-1.

The Problem:

Fiberglass insulation sags over time, leaving gaps.

Metal panels conduct heat, driving up HVAC costs.

The Solution:

XPS foam maintains its R-value (R-5.0 per inch) even in humidity.

PVC skins reflect solar radiation, keeping buildings cooler.

Case Study:

Walmart’s Texas distribution center slashed cooling costs by 40% after switching to PVC XPS panels.

NASA’s research confirms zero thermal bridging, meaning no cold spots.

Pro Tip: Always check for FM Global certification—cheap imitations fail fire tests.

PVC Sandwich Panel Cost: 2025 Price Breakdown (And How to Save 25%)

Let’s talk numbers—because at the end of the day, cost dictates everything. Here’s what you’ll actually pay for PVC sandwich panels in 2024:

Basic 20mm panels: $12-$18/sqft (perfect for interior walls)

Insulated 40mm panels: $22-$30/sqft (ideal for cold storage)

Fire-rated panels: $35-$50/sqft (required in NYC high-rises)

But here’s the kicker: While upfront costs might seem higher than metal, you’ll save 25% on labor (no welding needed) and 30% on energy bills.

Real Example:

Costco’s last warehouse saved $250,000 by switching to PVC.

Home Depot’s DIY kits (using PVC panels) are flying off shelves.

Takeaway: Don’t just look at sticker price—calculate lifetime savings.

Panel PVC Sandwich ALB: The Architect’s Dream for Sleek, Modern Designs

Tired of boring, boxy buildings? Panel PVC Sandwich ALB (that’s Aluminum-Laminated Board) gives you endless design flexibility without sacrificing durability.

The Problem:

The Solution:

ALB finishes mimic wood, stone, or even brushed metal.

Scratch-resistant surface (tested in Dubai’s sandstorms).

Case Study:

Apple’s latest store in Berlin used ALB panels for its sleek, seamless exterior.

LEED Gold projects love them for sustainable aesthetics.

Pro Tip: Pair with hidden fastener systems for a ultra-clean look.

Panadur PVC Sandwich Panel: Why European Contractors Swear By It

Across the pond, Panadur PVC sandwich panels are the gold standard for a reason. These German-engineered panels offer:

UV-resistant coatings (lasts 20+ years without fading)

Class B1 fire rating (meets EU’s strictest safety codes)

Noise reduction up to 32dB (perfect for hotels)

Real-World Use:

Warning: Only buy from certified suppliers—counterfeits fail within 5 years.

Panoline PVC Sandwich Panel: The Budget-Friendly Option That Doesn’t Sacrifice Quality

Not all PVC panels cost a fortune. Panoline PVC sandwich panels deliver 80% of the performance at 60% of the price.

The Problem:

The Solution:

Case Study:

Pro Tip: Ideal for budget-conscious retail builds.

Panel Sandwich PVC Leroy Merlin: What Makes Their Panels Different

Wondering why Leroy Merlin’s PVC sandwich panels dominate the DIY market? It’s their patented click-lock system that lets homeowners install 200 sqft in a day.

The Problem:

The Solution:

Real Example:

Takeaway: If you want easy installation, this is the way.