Why Choose Shanghe Sandwich Panels eps for Your Construction Projects

Wondering why Shanghe sandwich panels EPS stand out for your building needs? Here’s the straightforward answer: these panels deliver a powerful mix of performance, cost savings, and ease. Whether you’re working on industrial warehouses, commercial buildings, or residential projects, Shanghe panels offer reliable thermal insulation, lightweight design, and solid fire resistance—all backed by strict quality controls.

Here’s why Shanghe EPS sandwich panels are a smart choice:

- Superior insulation with low thermal conductivity (0.023 W/m·K) helps cut energy costs year-round

- Lightweight and easy to install, reducing both labor and project time

- Cost-effective alternative to traditional building materials like brick or concrete

- Fire resistant with B1 rating thanks to advanced fire-retardant additives

- Strong soundproofing and waterproofing for comfortable, durable spaces

- Eco-friendly and recyclable, supporting sustainable building goals

- Highly durable with minimal maintenance—built to last in harsh environments

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Plus, Shanghe’s panels come with customizable sizes, colors, and finishes, making it easy to match your project’s design and structural requirements. Their extensive experience serving the U.S. construction market ensures fast delivery, expert support, and a smooth building process.

Choosing Shanghe EPS sandwich panels means investing in quality, efficiency, and peace of mind from start to finish. Ready to build smarter? Let’s explore how these panels fit your project perfectly.

What Are EPS Sandwich Panels

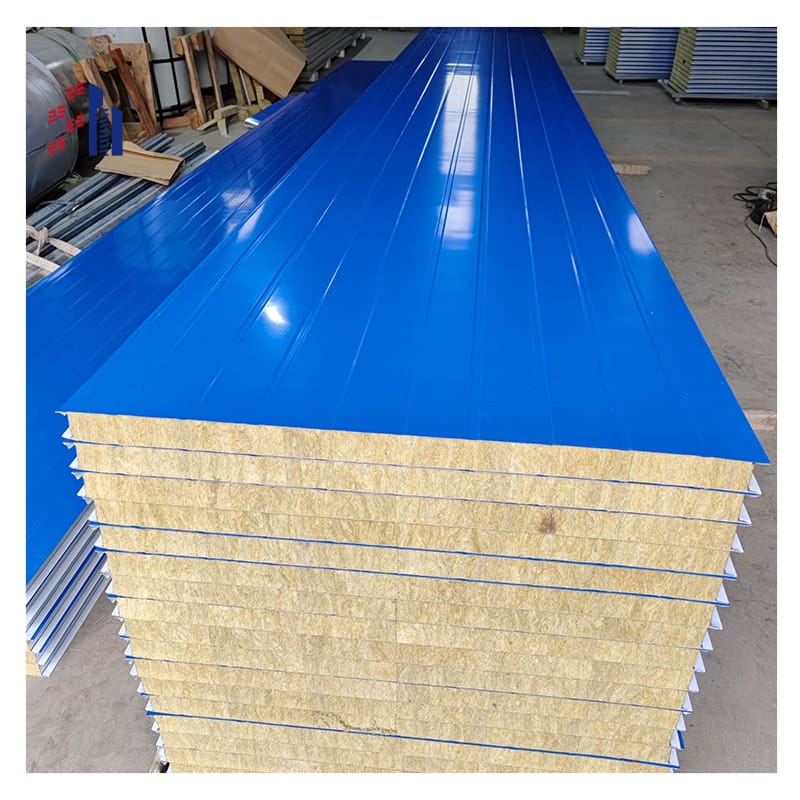

EPS sandwich panels are three-layer composite panels made up of galvanized steel or aluminum outer layers and an EPS (expanded polystyrene) core in the middle. This design combines the strength of steel or aluminum skin with the excellent insulation properties of EPS foam, creating a lightweight, durable, and highly efficient building material.

Key Components and Manufacturing Process

- Outer Layers: Usually galvanized steel or aluminum sheets that protect the core and provide structural support.

- Core Material: EPS foam, which is a type of polystyrene known for its thermal insulation and lightweight properties.

- Manufacturing: The steel or aluminum panels are bonded to the EPS core through a controlled lamination process under heat and pressure to ensure strong adhesion and uniform thickness.

Comparison with Other Core Materials

Compared to other sandwich panel cores like PUR (polyurethane), PIR (polyisocyanurate), mineral wool, and phenolic foam, EPS offers a great balance of cost, thermal insulation, and weight. EPS panels generally have lower thermal conductivity and are more eco-friendly, while mineral wool and phenolic foam may provide better fire resistance but at a higher price point.

Shanghe Unique EPS Panel Technology and Quality Standards

Shanghe uses advanced EPS sandwich panel technology that meets strict quality controls to deliver consistent thickness, high bond strength, and superior thermal performance. Our panels comply with international standards like CE EN14509, ensuring safety, durability, and efficiency tailored to meet the demands of U.S. construction projects.

Benefits of Shanghe EPS Sandwich Panels

Shanghe EPS sandwich panels stand out because of their superior thermal insulation. With a low thermal conductivity of just 0.023 W/m·K, they keep your buildings energy-efficient and comfortable year-round.

These panels are lightweight, which makes installation quick and easy. That means less labor time and lower costs on the job site.

Compared to traditional building materials, Shanghe EPS panels are cost effective without sacrificing quality or performance.

Fire safety is a priority here. Our panels have a B1 fire resistance rating thanks to fire-retardant additives, providing peace of mind for your construction projects.

They also offer excellent sound insulation and waterproofing, helping create quiet, dry interiors.

On top of all this, they’re eco friendly and fully recyclable, perfect for meeting green building standards.

Durability is another strong point — these panels require low maintenance and can withstand the demands of various environments, keeping your investment solid over time.

Applications of Shanghe EPS Sandwich Panels

Shanghe EPS sandwich panels are a perfect fit for a wide range of construction projects thanks to their versatility and strong performance.

Industrial Buildings Warehouses Factories

These panels provide excellent insulation and durability for large industrial spaces. They help maintain stable indoor temperatures, making them ideal for warehouses and factories that need energy efficiency and easy maintenance.

Commercial Structures Shopping Malls Hypermarkets

For commercial buildings, Shanghe EPS panels offer a sleek, modern look while ensuring thermal comfort. Their lightweight nature speeds up construction, reducing downtime and cost.

Cold Storage and Food Industry Facilities

Because of their superior thermal insulation and waterproofing, these EPS insulated panels are widely used in cold rooms, freezers, and food processing plants where temperature control is critical.

Residential Projects Prefab Homes Modular Buildings

Shanghe EPS sandwich panels are popular in residential and prefab buildings. They allow faster build times and better energy efficiency, perfect for modern homes and modular construction.

Temporary Structures Site Offices Mobile Restrooms

Their lightweight and easy-install features make these panels useful for temporary setups like site offices or mobile restrooms, where quick assembly and transportability matter.

Case Studies Shanghe Successful Projects

We’ve helped numerous clients across the U.S. achieve their project goals—from industrial warehouses in Texas to cold storage units in California. Our panels consistently deliver on insulation, durability, and cost-effectiveness, making them a trusted choice in construction.

Technical Specifications of Shanghe EPS Sandwich Panels

Shanghe EPS sandwich panels come in a variety of thickness options to fit your project needs, including 50mm, 75mm, 100mm, and 125mm. This range gives you flexibility whether you’re aiming for stronger insulation or specific structural requirements.

The panels have a density of 12 to 16 kg/m³, providing a good balance between lightweight construction and solid load-bearing capacity. This makes them ideal for applications from industrial warehouses to prefab homes.

For surfaces, you can choose from galvanized steel, aluminum, or PPGI (Pre-Painted Galvanized Iron), depending on your desired finish and durability. These material options also help with corrosion resistance and weather protection.

Color options include a broad selection of RAL colors like standard white, blue, and red, allowing you to match aesthetic preferences easily without compromising strength.

Joint types for Shanghe EPS sandwich panels include tongue and groove and lapped joints, specifically designed for roof installations to ensure tight sealing and easy assembly.

All panels comply with international standards including CE and EN14509, ensuring reliable performance and quality that meets US and global construction codes.

Explore our full range of EPS sandwich panels for detailed specs and options.

Why Buy Shanghe EPS Sandwich Panels

Choosing Shanghe EPS sandwich panels means getting competitive pricing without sacrificing quality. Our panels are customizable to fit your specific project needs, whether it’s size, thickness, or color. This flexibility helps you get exactly what your construction requires.

We know timing is critical in construction, so Shanghe offers fast delivery and reliable local support across the United States. Our streamlined supply chain ensures your panels arrive on schedule, keeping your project on track.

Beyond just delivery, we provide expert installation guidance to help your team install panels quickly and correctly. Plus, our after-sales service is always ready to assist with any questions or issues, giving you peace of mind throughout your project.

Don’t just take our word for it—our customers consistently share positive testimonials highlighting the performance and reliability of our EPS insulated panels. We also hold industry certifications, so you know you’re working with a trusted supplier.

When compared to competitors, Shanghe stands out for quality, price, and service. We deliver high-value sandwich panel insulation solutions without the premium price tag, making us a smart choice for your building needs.

To explore our full range, check out our composite sandwich panels and see why Shanghe is the preferred partner for lightweight construction panels.

How to Choose the Right EPS Sandwich Panel for Your Project

Picking the right EPS sandwich panel can make a big difference in your project’s success. Here’s how to get it right:

Assess project needs

Start by understanding your key requirements: the level of insulation you need, fire resistance rating, and the structural load the panels must support.

Consider environmental factors

Think about climate conditions like humidity and temperature where the panels will be used. These affect the panel’s performance and durability.

Plan your budget

Look at cost versus benefits. Shanghe EPS panels are cost-effective, but choosing the right thickness and finish will impact your overall price. Make sure you’re balancing quality with budget.

Consult Shanghe experts

Don’t hesitate to reach out for advice. Shanghe’s team can help customize panel solutions to fit your specific needs, ensuring you get the best product for your project.

If you want to explore our range, check out our roof sandwich panels or exterior wall sandwich panels to see what might suit your project.

Installation Guide for Shanghe EPS Sandwich Panels

Pre Installation Checklist and Site Preparation

Before you start, make sure to:

- Clear and level the installation site

- Have all necessary tools ready: drills, screwdrivers, sealant, measuring tape, safety gear

- Inspect panels for any damage or defects

- Plan the panel layout to minimize cuts and waste

- Check environmental conditions, avoid installation during heavy rain or high winds

Step by Step Installation Process for Wall and Roof Panels

- Start with the frame – Ensure your structure is sturdy and leveled

- Position the first panel – Align it properly at the corner or edge

- Secure the panel – Use screws recommended by Shanghe to fasten panels to the frame

- Connect the next panel – Join using tongue and groove or lapped joints for a tight fit

- Seal the joints – Apply weatherproof sealant to prevent water and air infiltration

- Repeat for all panels – Follow the same method for both walls and ceilings or roofs

Tips to Ensure Proper Alignment and Sealing

- Use a level and laser measure to keep panels straight

- Don’t overtighten screws to avoid panel deformation

- Double-check seals at overlaps and corners

- Use compatible sealants for EPS sandwich panel materials

- Allow for slight panel expansion in warmer conditions

Common Mistakes to Avoid

- Installing without cleaning the substructure first

- Ignoring manufacturer’s fastening guidelines

- Skipping the sealing step, leading to leaks

- Cutting panels without proper tools or measurements

- Neglecting safety procedures during installation

Shanghe Professional Installation Services

For peace of mind and guaranteed results, Shanghe offers expert installation services. Our trained teams ensure your EPS insulated panels go up quickly, securely, and with perfect alignment, cutting down project time and rework. Reach out to us for support and professional handling on site.

For detailed product specs or more installation tips, explore our roof panel sandwich options and installation guides.