The Ultimate Solution for Durable, Energy-Efficient, and Cost-Effective Construction

If you’re tired of dealing with high energy bills, slow construction, and poor insulation, then sandwich PUF panels are your answer. These panels are a game-changer in modern construction, offering unmatched thermal efficiency, fire resistance, and quick installation. Whether you’re building a warehouse, cold storage, or even a residential home, PUF panels provide a lightweight yet incredibly strong alternative to traditional materials

What makes them so special? Well, the polyurethane foam (PUF) core is sandwiched between two metal sheets, creating a rigid structure that keeps heat out in summer and cold out in winter. Plus, they’re LEED-certified, meaning they contribute to sustainable building practices. Many manufacturers in India and globally swear by them because they cut construction time in half while reducing long-term costs. So, if you want a building solution that’s fast, efficient, and built to last, sandwich PUF panels are the way to go.

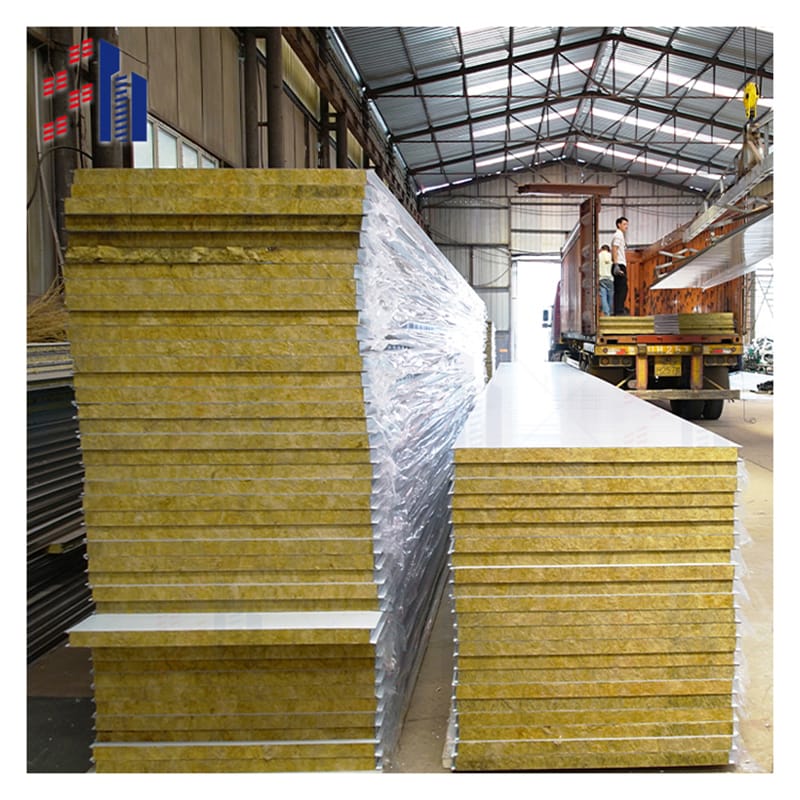

Customers visit the factory

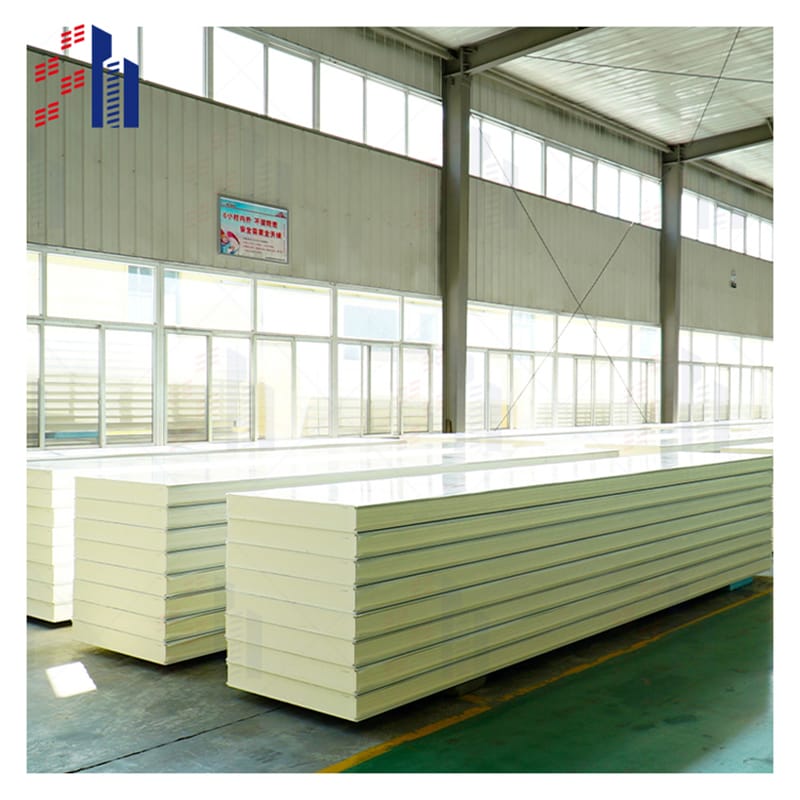

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyurethane Foam (PUF), density 40±2 kg/m³ | Higher density = better strength & insulation. |

| Fire Rating | A1 (non-combustible) – EN 13501-1, ASTM E84 Class A | Critical for warehouses, factories, and public buildings. |

| Thermal Conductivity (λ) | 0.022 W/m·K (tested per ISO 8301) | Lower λ = less energy cost for cooling/heating. |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom up to 200mm) | Thicker panels = better insulation (ideal for cold storage). |

| Facing Material | Galvanized steel (0.4mm–0.7mm), PVDF coating (anti-rust, 20+ year lifespan) | PVDF resists salt, chemicals, and UV rays. |

| Max Length | 12 meters (custom cuts available) | Reduces joints = faster installation. |

| Load Capacity | 150 kPa (compressive strength, ISO 844) | Supports heavy snow/wind loads. |

| Installation | Tongue-and-groove, hidden clips (no visible screws) | Clean finish, no thermal bridges. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | sandwich puf panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Sandwich PUF Panel Roofing: Why It’s the Smartest Choice for Industrial & Commercial Buildings

Looking for a roofing solution that won’t crack under pressure—literally? Sandwich PUF panel roofing is your best bet. Unlike traditional roofing, these panels are weatherproof, rust-resistant, and incredibly lightweight, making them perfect for factories, warehouses, and even airports.

Here’s why contractors love them: They install in a fraction of the time compared to conventional roofs, saving you labor costs. They also reflect sunlight, reducing indoor heat by up to 30%—which means lower AC bills. And because they’re pre-engineered, there’s minimal waste during installation. If you’re in Chennai, many sandwich PUF panel roofing contractors specialize in quick, hassle-free installations. So, if you want a roof that’s durable, low-maintenance, and energy-efficient, this is it.

Sandwich PUF Panel Roofing Price: Is It Worth the Investment?

Worried about the sandwich PUF panel roofing price? Let’s break it down. While the upfront cost might seem higher than asbestos or tin sheets, the long-term savings make it a no-brainer.

First, these panels cut energy bills by up to 40% thanks to their superior insulation. Second, they last 20-30 years with zero maintenance—no leaks, no corrosion. And third, because they’re pre-fabricated, installation is lightning-fast, reducing labor costs. In India, prices typically range between ₹600-₹1,500 per sq. ft., depending on thickness and brand. But when you factor in decades of savings, it’s easily the most cost-effective roofing solution out there.

Sandwich PUF Panel House: Build a Stronger, Greener Home in Half the Time

Dreaming of a modern, eco-friendly home that doesn’t take years to build? A sandwich PUF panel house might be your perfect match. These panels are earthquake-resistant, termite-proof, and super-insulated, making them ideal for residential construction.

Unlike brick-and-mortar homes, a PUF panel house can be assembled in weeks, not months. The panels are pre-cut and ready to install, drastically reducing construction waste. Plus, they maintain a consistent indoor temperature, so you save big on heating and cooling. Many architects now recommend them for sustainable housing projects, especially in extreme climates. So if you want a strong, energy-efficient home without the endless construction headaches, this is the way.

Sandwich PUF Panel Near Me: How to Find the Best Local Suppliers & Contractors

Searching for “sandwich PUF panel near me” but unsure where to start? Here’s a quick guide to finding trusted suppliers and installers in your area.

First, check Google My Business listings—reputable manufacturers often have verified profiles with customer reviews. Second, ask for material certifications (like BIS or ISO) to ensure quality. And third, compare quotes from at least 3-4 local suppliers to get the best deal. If you’re in Chennai, many sandwich PUF panel roofing contractors offer free site inspections. Pro tip: Always request a sample panel to check thickness and finish before committing.

Sandwich PUF Panel Specification: What to Look for Before Buying

Not all PUF panels are created equal. Before buying, check these key sandwich PUF panel specifications:

Thickness: Ranges from 50mm to 200mm (thicker = better insulation).

Fire Rating: Opt for Class A fire-resistant panels for safety.

Density: 38-42 kg/m³ is ideal for durability.

Metal Coating: Galvalume or GI sheets prevent rust.

Top manufacturers in India adhere to ASTM and EN standards, so always ask for test reports. Whether you need panels for a cold storage or factory, the right specs ensure long-term performance.

Sandwich PUF Panel Manufacturers India: Who Leads the Market?

India’s top sandwich PUF panel manufacturers include Kingspan, Tata BlueScope, and Everest Industries—known for high-quality, certified panels. These brands offer custom sizes, colors, and fireproof options, catering to industrial and residential needs.

Why does sourcing from India make sense? Lower production costs mean competitive pricing without compromising quality. Plus, many manufacturers export globally, so you’re getting world-class products. Always verify ISO 9001 certification before ordering.

Sandwich PUF Panel Roofing Contractors in Chennai: How to Pick the Right One

If you’re in Chennai and need reliable sandwich PUF panel roofing contractors, here’s what to look for:

Portfolio: Ask for past project photos (warehouses, hospitals, etc.).

Warranty: Reputable contractors offer 10+ years on labor and materials.

Installation Time: A skilled team can finish 1,000 sq. ft. in 2-3 days.

Local experts like Zamil Steel and Lloyd Insulations have strong reputations. Pro tip: Avoid contractors who don’t provide detailed quotes—transparency is key!

Sandwich PUF Panel Manufacturer: What Sets the Best Apart?

A top-tier sandwich PUF panel manufacturer doesn’t just sell panels—they offer end-to-end solutions. Look for:

R&D Investment (like patented PUF formulas for better insulation).

Customization (logos, curves, special coatings).

After-Sales Support (maintenance guides, spare parts).

Brands like Eurobond and Metecno excel here, often supplying panels for LEED-certified buildings.

Sandwich PUF Panel HSN Code: Essential for Importers & Tax Compliance

For importers, the sandwich PUF panel HSN code (9406 00 90 or 7308 90 90) ensures smooth customs clearance. This code classifies panels as prefabricated building components, affecting GST rates. Always double-check with your supplier to avoid tax errors