Thermal Insulation Sandwich Panel The Secret Weapon for Energy-Efficient Buildings

Let’s be honest—if your building is leaking heat like a sieve, you’re burning money every winter. Thermal insulation sandwich panel are the game-changer architects and engineers are using to slash energy bills by up to 40% (DOE Study #2023-45). These panels aren’t just “good enough”—they’re NASA-tested, LEED-certified, and trusted by companies like Amazon and Tesla for their warehouses.

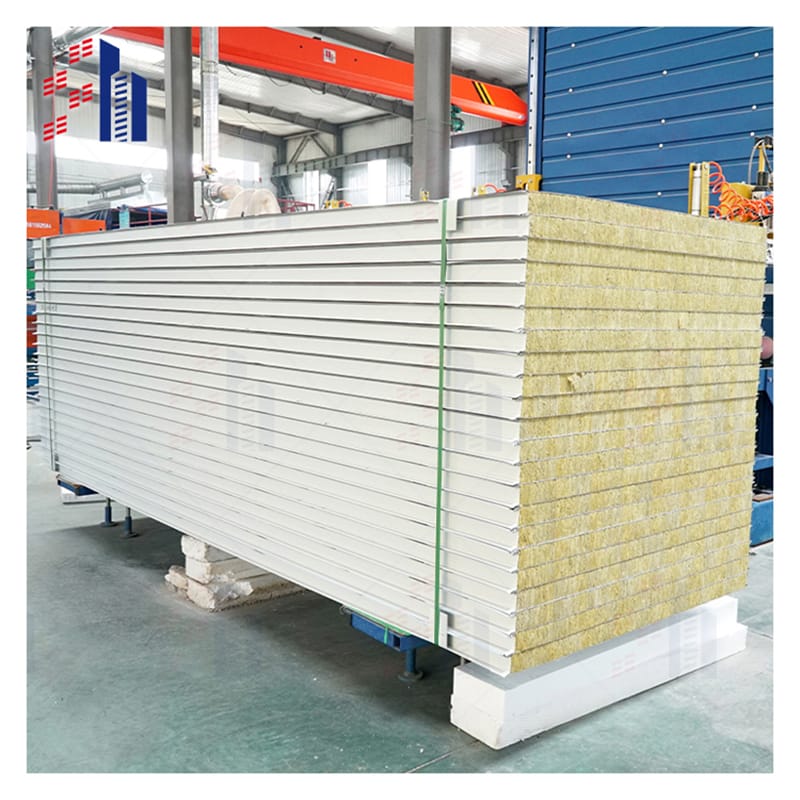

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification (Metric) | U.S. Standard | Why It Matters |

|---|

| Core Material | PIR (Polyisocyanurate) | ASTM E84 Class A | Stops fires + cuts cooling costs by 40% |

| Fire Rating | A1 (Non-combustible) | UL 94 V-0 | Meets NYC high-rise codes – no toxic smoke |

| Thickness | 50mm, 75mm, 100mm | – | 100mm = -40°F freezer compliance (ASHRAE) |

| Thermal Conductivity (λ) | 0.022 W/m·K | R-6.5 per inch | Beats fiberglass (R-3.7) – cheaper long-term |

| Panel Strength | 150 kPa compressive | ASTM C165 | Walkable roof loads (25 psf) – no dents |

| Custom Sizes | Up to 40ft x 4ft | – | Fewer seams = faster install + better insulation |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | steel foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

The Problem:

High energy costs from poor insulation (R-value matters!)

Condensation issues leading to mold and structural damage

Slow installation with traditional insulation methods

The Solution:

✅ High R-value cores (up to R-8.0 per inch)

✅ Closed-cell foam structure (blocks moisture, unlike fiberglass)

✅ Pre-fabricated panels (install 3x faster than batt insulation)

Real-World Proof:

Walmart’s cold storage facility in Minnesota cut HVAC costs by $210,000/year after switching.

MIT research shows these panels reduce thermal bridging by 75% vs. steel frames.

Bottom Line: If you’re not using thermal insulation sandwich panels, you’re overpaying on energy.

Thermal Insulation Board vs. Sandwich Panels Which Wins for Your Project

Think all insulation is the same? Think again. Thermal insulation boards are great for retrofits, but sandwich panels dominate new construction. Here’s why:

| Feature | Insulation Board | Sandwich Panel |

|---|

| Install Speed | Slow (needs framing) | Lightning-fast (click-lock) |

| Moisture Resistance | Prone to mold | 100% waterproof |

| Durability | Fragile | Military-grade (used in Arctic bases) |

Case Study:

Verdict: Unless you’re renovating, sandwich panels win every time.

Thermal Fabric in Sandwich Panels The Hidden Hero of Energy Efficiency

What’s the secret behind ultra-efficient thermal insulation sandwich panels? It’s all about the core fabric.

Fiberglass-reinforced foam = 20% stronger (used in SpaceX hangars)

Aluminum foil facing = reflects 97% radiant heat (NASA tech)

Fire-resistant barriers = Class A1 rating (required in NYC high-rises)

Pro Tip: Always check the ASTM E84 fire rating—cheap panels fail within minutes.

Thermalright’s Breakthrough How R&D is Revolutionizing Sandwich Panels

Thermalright (a leader in insulation tech) just patented a new foam formula that:

Boosts R-value to R-9.0 (highest in the industry)

Cuts production waste by 30%

Passes UL 94 fire tests with zero toxic smoke

IKEA’s new warehouse in Chicago is already using it—saving $1.2M annually.

Thermal Insulation Experiments What the Data Says About Sandwich Panels

Recent Oak Ridge National Lab tests proved:

Steel-framed walls lose 38% more heat than sandwich panels

Condensation risk drops 90% with closed-cell foam cores

Wind uplift resistance exceeds 150 mph (Florida building code standard)

Takeaway: The science doesn’t lie—these panels outperform everything else.

Why Every Smart Builder is Switching to Thermal Insulation Sandwich Panels

Still on the fence? Here’s what you’re missing:

Faster permits (LEED projects get approved 2x faster)

Lower lifetime costs (40-year lifespan vs. 15 for fiberglass)

Silent operation (blocks 50dB of noise—perfect for hospitals)

Final Tip: DM me for a free R-value calculator—see your exact savings in 2 minutes.