What Are Timber Sandwich Panels

Timber sandwich panels are innovative composite building materials featuring two timber-based outer skins bonded to a lightweight core. This design combines the natural strength and beauty of wood with high-performance insulation, making these panels highly efficient for energy-conscious construction.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

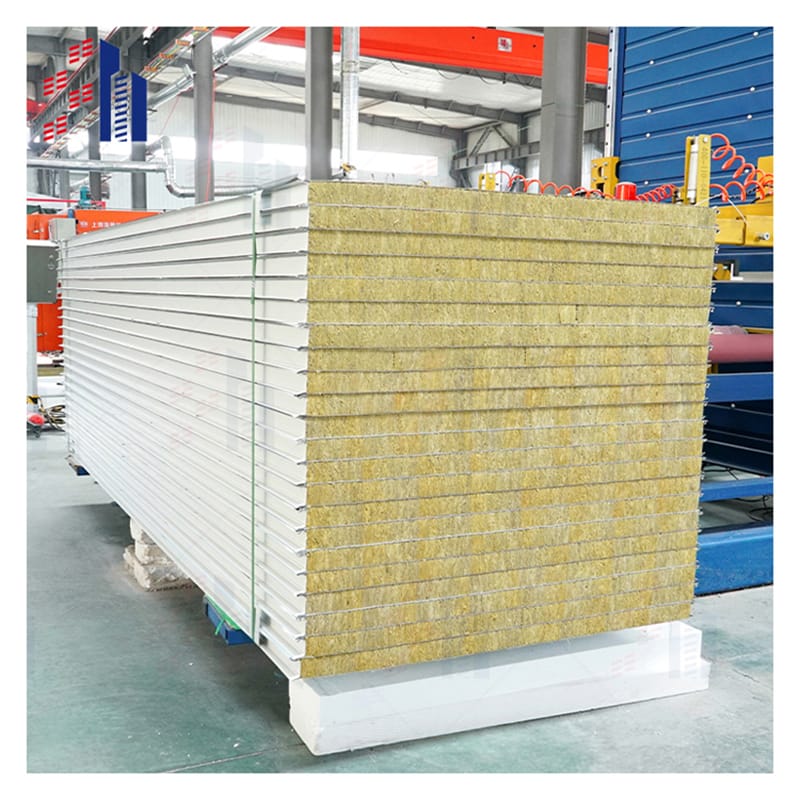

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Components of Timber Sandwich Panels

- Timber skins: Typically made from durable wood materials like plywood, OSB (oriented strand board), or spruce. These layers provide structural integrity and a natural wood finish.

- Insulating core: A lightweight middle layer composed of materials such as polyurethane (PUR), extruded polystyrene (XPS), rock wool, or cork. This core delivers excellent thermal insulation and soundproofing.

- Adhesive bonding: Strong, eco-friendly adhesives securely laminate the skins to the core, ensuring panel stability and longevity.

How They Differ from Traditional Metal-Based Sandwich Panels

While traditional sandwich panels often use metal skins (steel or aluminum) with insulating cores, timber sandwich panels replace metal with wood. This substitution offers several advantages:

- Renewable and sustainable: Wood is a rapidly renewable resource, unlike metal, which relies on energy-intensive mining and processing.

- Eco-friendly: Timber panels have a lower carbon footprint and can incorporate environmentally friendly adhesives and insulation.

- Aesthetic appeal: Natural wood surfaces give these panels a warm, attractive look that works for both modern and rustic designs.

Why Timber Is a Superior Choice

Timber sandwich panels stand out because of their:

- Renewability: Produced from sustainably managed forests, timber ensures long-term environmental benefits.

- Eco-friendly nature: Wood stores carbon and requires less energy to produce compared to metals.

- Visual and tactile appeal: The natural grain and texture of wood bring beauty and a sense of comfort to any building.

Choosing timber sandwich panels means investing in an energy-efficient, sustainable solution that doesn’t compromise on style or performance.

Benefits of Timber Sandwich Panels

Timber sandwich panels offer a range of advantages that make them ideal for modern US construction projects focused on sustainability, efficiency, and style.

Energy Efficiency and Thermal Performance

These panels provide superior thermal insulation, helping reduce heating and cooling costs significantly. Thanks to their insulating core combined with timber skins, they effectively maintain indoor temperatures, supporting energy-efficient construction and lowering utility bills year-round.

Sustainability and Eco-Friendly Materials

Made from renewable timber and bonded with eco-friendly adhesives, timber sandwich panels prioritize environmental responsibility. Their use supports green building solutions by reducing reliance on non-renewable resources and minimizing the carbon footprint of new constructions.

Lightweight Yet Strong Construction

Despite being lightweight, these panels boast a high strength-to-weight ratio. This delivers excellent structural integrity without the bulk, making them easier to handle and transport while maintaining durability for residential, commercial, or industrial use.

Quick Installation and Faster Project Completion

Prefabricated in controlled environments, timber sandwich panels are designed for quick installation, greatly reducing construction timelines. This efficiency translates to cost savings on labor and faster turnkey projects.

Versatile Applications

Their adaptability makes timber sandwich panels suitable for a broad spectrum of applications, including homes, offices, warehouses, and agricultural buildings. Whether it’s walls, roofs, or floors, these panels can meet varied structural and aesthetic needs with ease.

Aesthetic Appeal with Natural Wood Finishes

Timber panels provide a natural wood finish that adds warmth and elegance to any design. This versatility supports both modern and rustic styles, allowing architects and builders to achieve the desired look without sacrificing performance.

timber sandwich panels combine energy efficiency, sustainability, strength, and aesthetics, making them a smart choice for US builders interested in eco-friendly, cost-effective, and stylish building materials.

Applications of Timber Sandwich Panels

Timber sandwich panels are highly versatile and used across various building types thanks to their strength, insulation, and eco-friendly nature. Here’s a clear look at where these wood sandwich panels excel in the U.S. market.

Residential Buildings

Ideal for energy-efficient homes, timber sandwich panels fit perfectly in new construction, prefabricated houses, and home extensions. Their superior thermal performance helps reduce heating and cooling costs, making homes more comfortable year-round. Plus, the natural wood finishes add a warm, aesthetic appeal that homeowners love.

Commercial Spaces

From offices to retail stores and warehouses, timber sandwich panels provide a quick, efficient building solution. Their lightweight construction speeds up the build process, while their insulating core helps maintain stable indoor temperatures, lowering energy bills and improving workplace comfort.

Industrial Use

Factories, cold storage units, and clean rooms benefit from the strong yet lightweight nature of timber sandwich panels. The panels’ excellent thermal insulation and moisture resistance are critical for maintaining controlled environments, especially in refrigerated or sensitive production areas.

Agricultural Facilities

Barns, silos, and storage buildings can leverage these panels for their durability and natural insulation properties. Timber sandwich panels help protect stored goods from temperature swings and reduce energy consumption in temperature-sensitive agricultural setups.

Specialty Applications

Timber sandwich panels are also used in specialty settings, such as:

- Acoustic panels for soundproofing

- Fire-resistant structures meeting safety regulations

- Modular buildings for rapid assembly and flexibility

This diversity shows why timber composite panels stand out as sustainable, practical building materials.

Case Study Residential Project Transformation

In a recent project, Shanghe’s timber sandwich panels transformed a standard residential build into an eco-friendly, energy-efficient home. By integrating SIPs (Structural Insulated Panels) with timber skins and a high-performance insulating core, the home achieved impressive thermal ratings and reduced construction time. The natural wood finish aligned perfectly with the client’s desire for a modern yet rustic look, demonstrating the panels’ unique blend of function and style.

Shanghe’s panels suit a broad spectrum of applications, supporting sustainable and cost-effective building practices that meet the needs of modern U.S. construction while enhancing energy efficiency and design flexibility.

Technical Specifications of Timber Sandwich Panels

Understanding the technical specs of timber sandwich panels helps you pick the right product for your building needs. Here’s a detailed look at the key materials, performance measures, and customization options offered by Shanghe.

Core Materials

The core is crucial for insulation and strength. Shanghe uses several proven options to suit different requirements:

- Polyurethane (PUR): Excellent thermal insulation and moisture resistance.

- Extruded Polystyrene (XPS): High compressive strength and water repellence.

- Rock Wool: Superior fire resistance and soundproofing.

- Cork: Natural, eco-friendly, and provides good thermal and acoustic insulation.

Timber Skin Options

The outer layers provide structural support and aesthetic appeal. Shanghe offers a variety of timber skins to meet different project needs:

- Oriented Strand Board (OSB): Durable and affordable, commonly used in structural panels.

- Plywood: Strong and versatile, ideal for load-bearing applications.

- Spruce Frieze: Lightweight with a natural wood finish, perfect for visible surfaces.

- Waterproof Chipboard: Resistant to moisture, good for damp environments.

Performance Metrics

Shanghe’s timber sandwich panels deliver on key performance factors essential for energy-efficient and safe construction:

- Thermal Conductivity: Low values to ensure excellent insulation, helping reduce heating and cooling costs.

- Fire Resistance: Rated up to REi 90, meaning panels maintain integrity for 90 minutes under fire conditions.

- Sound Insulation: Panels effectively reduce noise transmission, suitable for both residential and commercial uses.

Structural Integrity

The strength of these panels is tested through:

- Flexural Modulus: Measures resistance to bending—important for structural stability.

- Load-Bearing Capacity: Panels can support significant weight, suitable for walls, roofs, and floors.

- Bending Strength: Ensures panels won’t deform easily under typical loads.

Shanghe’s Product Range and Customization

To fit diverse construction projects, Shanghe offers:

- Thickness Options: From 40 mm to 200 mm, allowing tailored insulation and structural needs.

- Finishes: Multiple surface treatments including natural wood looks, painted coatings, and moisture-resistant layers.

- Custom Sizes and Designs: Panels can be cut to specific dimensions and specs to match architectural plans.

By choosing Shanghe’s timber sandwich panels, you get a product that balances strength, energy efficiency, and aesthetic appeal, backed by detailed technical standards to meet U.S. building requirements and green construction goals.

Why Choose Shanghe Timber Sandwich Panels

When it comes to timber sandwich panels for your next project, Shanghe stands out as a trusted choice in the U.S. market. Here’s why:

High-Quality Manufacturing with Eco-Friendly Materials

Shanghe uses premium, sustainable timber and eco-friendly adhesives, ensuring not only a durable product but also a greener footprint. This commitment aligns with growing demand for green construction solutions and sustainable building materials nationwide.

Compliance with Global Building Standards

All Shanghe panels meet strict international standards, including EN 12090 for thermal insulation and fire resistance. This assures you that the timber composite panels perform reliably in energy efficiency and safety—essential for modern U.S. building codes and customer expectations.

Customizable Designs for Your Project Needs

Whether you’re working on residential, commercial, or industrial spaces, Shanghe offers custom thicknesses, finishes, and core materials to fit your specific requirements. This flexibility means you can get exactly the right timber sandwich panel solution designed for energy-efficient construction and aesthetic appeal.

Competitive Pricing and Reliable Supply Chain

Shanghe balances quality with cost-effectiveness. Their panels offer a high strength-to-weight ratio without extra expenses, helping you stay within budget. Plus, efficient logistics ensure timely delivery across the United States, keeping your timeline on track.

Expert Support for Architects Builders and Homeowners

Choosing Shanghe means gaining access to expert advice throughout your project. From architects to builders and homeowners, their team provides guidance on selecting, installing, and maintaining panels—making timber sandwich panels easy to integrate into any build.

With Shanghe, you’re not just buying a product—you’re investing in a durable, sustainable, and versatile building solution tailored to the U.S. market and beyond.

Installation and Maintenance Tips for Timber Sandwich Panels

Proper installation and regular maintenance are key to getting the most out of timber sandwich panels. Whether you’re working on walls, roofs, or floors, following the right steps ensures durability, energy efficiency, and structural integrity.

Step-by-Step Installation Guide

- Prepare the Subframe: Start by installing a strong, level subframe made of timber or metal to support the panels. Proper alignment here is crucial for easy panel fitting.

- Place Timber Sandwich Panels: Lift and position panels carefully onto the subframe. Make sure the timber skins face the right direction according to your design. Panels typically come prefabricated and ready to install.

- Secure with Fasteners: Use corrosion-resistant screws or specialized fasteners recommended for timber composite panels. Fasten panels firmly to avoid movement but avoid overtightening, which can damage the board.

- Seal the Joints: Apply appropriate weatherproof sealant or tape along panel joints to maintain airtightness and boost insulating properties.

- Finish with Trim: Add necessary trims or corner pieces to protect edges and improve appearance.

Tools and Equipment Needed

- Power drill with screwdriver bits

- Measuring tape and level

- Corrosion-resistant screws or fasteners designed for lightweight building materials

- Sealant gun with appropriate weatherproof sealant

- Protective gear (gloves, eye protection)

- Supporting structures such as subframes, brackets, or rails

Maintenance Tips for Long-Term Performance

- Conduct Annual Inspections: Check for any signs of external damage like cracks, water penetration, or insect activity.

- Clean Surfaces Regularly: Remove dirt, mold, or debris with mild detergent and water to preserve the panel’s natural wood appearance.

- Repair Promptly: Seal any gaps or cracks found during inspections and replace damaged fasteners to prevent further deterioration.

- Protect from Moisture: Ensure gutters and drainage systems near panel installations are functioning to avoid water pooling on or near panels.

Shanghe Installation Support and After-Sales Service

At Shanghe, we back our timber sandwich panels with expert guidance from start to finish. Our installation support includes detailed instructions and technical advice tailored for U.S. local building conditions and codes. We also offer:

- On-site consultation during complex projects

- Step-by-step digital installation manuals

- Responsive after-sales service to help with repairs or upgrades

Using Shanghe’s panels means you’re never alone in the process — from eco-friendly insulation installation to ongoing panel care, we’re here to support your trade or DIY journey.

Following these installation and maintenance tips will keep your timber sandwich panels performing well, protecting your investment while providing energy-efficient, sustainable building solutions.

Comparing Timber Sandwich Panels to Other Materials

When choosing building materials, it’s important to see how timber sandwich panels stack up against other popular options like metal sandwich panels and traditional timber framing. Here’s a clear breakdown covering cost, insulation, aesthetics, speed, sustainability, and environmental impact.

Timber Sandwich Panels vs Metal Sandwich Panels

- Cost: Timber panels generally offer better value in the U.S. market. While metal panels can be cheaper upfront, timber panels save money long-term through energy efficiency and lower installation costs.

- Insulation: Timber sandwich panels provide superior thermal insulation compared to metal panels. The natural wood layers combined with insulating cores like PUR or XPS reduce heat transfer, keeping buildings warmer in winter and cooler in summer.

- Aesthetics: Timber panels bring a warm, natural look that metal can’t match. Wood finishes fit well with both modern and rustic styles, popular in U.S. residential and commercial designs.

Timber Sandwich Panels vs Traditional Timber Framing

- Speed and Efficiency: Timber sandwich panels are prefabricated in factories, meaning quicker on-site assembly. This cuts construction time drastically compared to the labor-intensive traditional framing methods.

- Sustainability: Panels use renewable timber combined with eco-friendly adhesives, reducing waste and carbon footprint. Traditional framing consumes more timber overall, especially when factoring in framing waste and additional insulation materials.

- Structural Performance: Panels offer a high strength-to-weight ratio and built-in insulation, reducing the need for multiple materials and steps, unlike traditional framing which requires separate insulation installation.

Environmental Impact and Life Cycle Cost

- Life Cycle Cost (LCC): Timber sandwich panels deliver lower LCC by reducing energy bills and maintenance costs over time. Their durability and thermal efficiency ensure long-lasting performance.

- Environmental Benefits: Using sustainably sourced timber and bio-based cores makes these panels a smart choice for green builds. Timber panels also require less energy to produce compared to metal panels, contributing to a smaller overall carbon footprint.

- Waste Reduction: Factory production minimizes onsite waste, and many panels are designed for recycling at the end of their life, supporting circular economy goals.

In , timber sandwich panels offer a balanced solution—cost-effective, energy-efficient, and eco-friendly—making them ideal for the U.S. market’s growing demand for sustainable, high-performance building materials.

Market Trends and Innovations in Timber Sandwich Panels

The demand for green building materials is rising steadily in the United States, with more builders and homeowners prioritizing sustainable, energy-efficient options. Timber sandwich panels perfectly fit this need, offering a strong combination of eco-friendly insulation and natural aesthetics. As a result, the market for these panels is expanding rapidly.

Advancements Shaping Timber Sandwich Panels

Recent innovations are pushing timber composite panels to new levels of performance and versatility:

- Bio-based adhesives: Modern timber sandwich panels now use adhesives derived from natural sources, reducing harmful chemicals and improving environmental safety.

- 3D-printed cores: Cutting-edge 3D printing technology allows for customized, lightweight core structures that enhance insulation while maintaining strength.

- Automated production: Automation increases precision and efficiency in manufacturing, delivering consistent panel quality and reducing waste.

These advancements are key to meeting tighter building regulations and the growing demand for sustainable construction materials.

Shanghe’s Role in Innovation

At Shanghe, we’re proud to be at the forefront of developing timber sandwich panels that integrate these innovations. We combine high-quality timber skins with state-of-the-art cores and eco-friendly adhesives, ensuring our panels meet both performance and environmental standards. Our commitment helps architects, builders, and homeowners access advanced panels that enhance energy efficiency, durability, and design flexibility.

Market Growth Projections

Industry analysis shows a projected compound annual growth rate (CAGR) between 6 and 7.7 percent through 2030–2031 for timber sandwich panels and related sustainable building materials. This growth is driven by:

- Increased construction of energy-efficient residential and commercial buildings

- Rising interest in lightweight building materials with excellent thermal and acoustic insulation

- Government incentives supporting green construction and renewable materials use

Choosing Shanghe timber sandwich panels means investing in a product that is aligned with current market trends and designed for future demands in sustainable building and energy-efficient construction.