Why Wood Sandwich Panels Outperform Metal for Eco-Friendly & Cost-Efficient Building?

- Let’s cut to the chase—if you’re tired of dealing with cold, noisy, and expensive metal sandwich panels, wood sandwich panel are your answer. These panels combine sustainability with top-tier performance, offering better insulation, natural aesthetics, and easier installation. Unlike metal, wood sandwich panels don’t conduct heat or sound as much, making them perfect for energy-efficient buildings. Plus, they’re lighter, which means lower shipping and labor costs

- According to LEED-certified architects, wood-based construction reduces carbon footprints by up to 30% compared to steel. And let’s be real—who wants a building that feels like an industrial freezer? Wood sandwich panels maintain a comfortable indoor temperature while cutting down on heating and cooling bills. Whether you’re working on a residential project or a commercial space, these panels deliver durability without sacrificing style.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

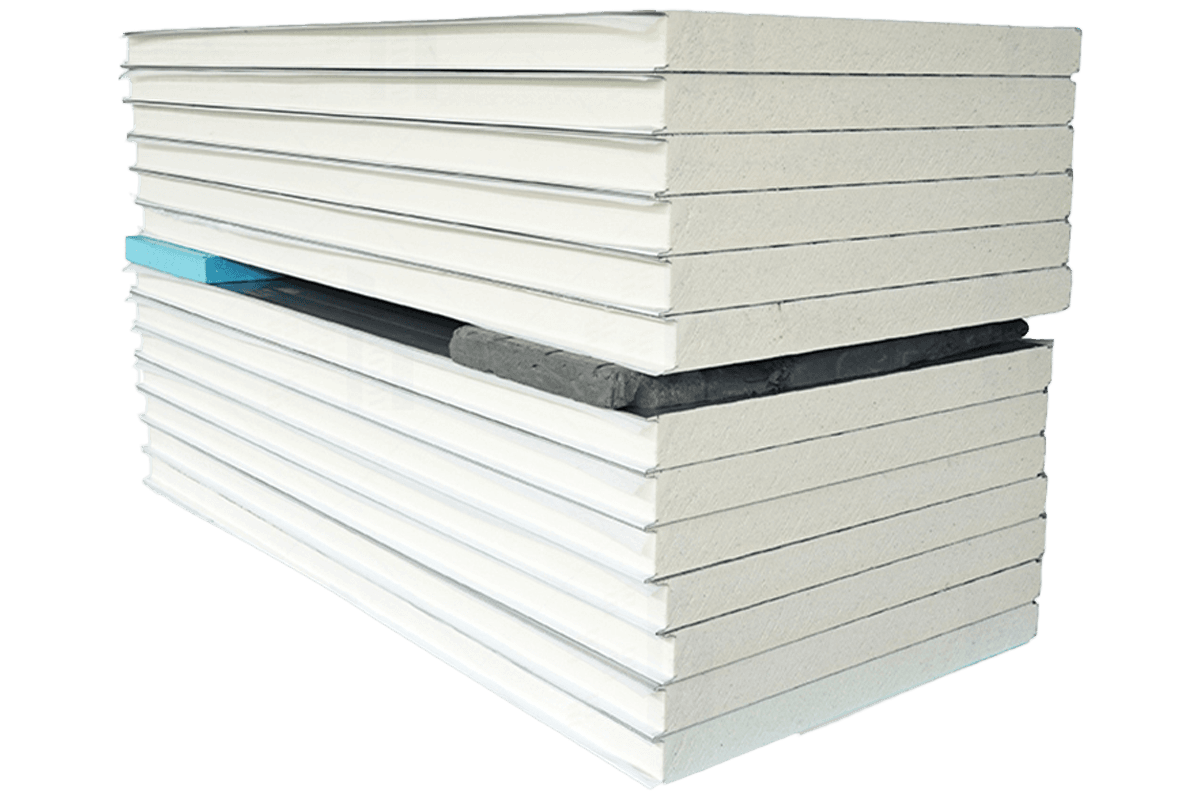

| Core Material | High-density PU foam (150kg/m³) / Mineral wool (for fireproofing) | Lighter than solid wood, better insulation |

| Facing Layers | 3mm Oak/Birch veneer or HDF (water-resistant coating optional) | Natural wood look, scratch-resistant |

| Panel Thickness | 30mm, 50mm, 80mm (customizable up to 120mm) | Thicker = better insulation for cold climates |

| Fire Rating | Class B (EN 13501), Class A optional (with mineral wool core) | Meets EU/US building codes |

| Load Capacity | Up to 250kg/m² (static load) | Safe for walls, floors, and ceilings |

| Thermal Conductivity | 0.022 W/m·K (PU core) / 0.038 W/m·K (mineral wool) | Reduces heating/cooling costs by ~30% |

| Moisture Resistance | Swelling <0.5% (72hrs, humidity 95%) | No mold, lasts longer in wet climates |

| Custom Sizes | Max. 4m length, 1.2m width (larger sizes consult us) | Fits most designs without wasteful cutting |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | wood sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Wood sandwich panel: The Secret to Noise-Free Spaces Without Ugly Foam

Fed up with those cheap foam panels that look like they belong in a recording studio from the ‘90s? Wood slat acoustic panels are the sleek, modern solution. They absorb sound just as effectively (if not better) while blending seamlessly into your design. Restaurants, offices, and even home theaters are switching to these because, well, nobody wants their walls to look like a science experiment.

The trick? The slats create air gaps that disrupt sound waves, reducing echo without killing the vibe. And unlike fabric-wrapped panels that stain easily, wood slat acoustic panels are durable and easy to clean. Pro tip: Pair them with wood sandwich panels for a fully sound-optimized space that still looks high-end.

Wood Panel Walls That Don’t Warp, Crack, or Look Cheap

Let’s face it—cheap wood panels warp, crack, and end up looking like a DIY disaster. But high-quality engineered wood panels (like Woodtec or Wood One) solve all that. These panels use advanced adhesives and pressure treatments to resist moisture and temperature changes, meaning no more gaps or buckling after a few seasons.

Contractors love them because they install fast, and designers love them because they mimic real wood grain without the maintenance. Whether you’re going for a rustic barn look or a sleek modern finish, today’s wood panels are built to last. Bonus: They’re often made from sustainable sources, so you’re not trashing the planet for good aesthetics.

Woodtec vs. Wood One: Which Premium Wood Panel Actually Lasts Longer?

Alright, let’s settle this—Woodtec and Wood One are two of the biggest names in high-end wood panels, but which one’s worth the investment? Woodtec is known for its ultra-realistic wood textures and fade-resistant coatings, while Wood One focuses on extreme durability (think scratch-proof surfaces for high-traffic areas).

If you’re doing a luxury project where looks matter most, Woodtec’s your go-to. But if you need something that can handle kids, pets, or heavy commercial use, Wood One’s reinforced core is the winner. Both beat traditional wood hands-down because they won’t rot or require constant refinishing.

Sandwich Panel Wood Color Options That Actually Match Your Design

Picking the wrong wood color for your sandwich panels can turn a high-end project into a Pinterest fail real quick. The good news? Modern manufacturing lets you customize shades from warm oak to cool walnut—without worrying about uneven staining.

Here’s the key: Always order physical samples before committing. Lighting changes how wood tones appear, and what looks perfect online might clash in person. Pro designers often use sandwich panel wood color swatches to ensure everything from flooring to cabinetry flows seamlessly.

Metal Sandwich Panel Regrets? Why Builders Are Switching Back to Wood

Metal sandwich panels were the “future”… until people realized they’re loud, hard to insulate, and prone to condensation (hello, mold risks). Now, smart builders are switching back to wood sandwich panels for better thermal performance and easier modifications.

Ever tried cutting or drilling metal panels on-site? It’s a nightmare. Wood, on the other hand, adjusts easily without specialized tools. And since wood naturally regulates humidity, you won’t deal with that dreaded “sweating metal” effect in temperature shifts. For long-term value and livability, wood wins.