What Are XPS Foam Sandwich Panels

XPS foam sandwich panels are advanced composite materials designed for superior strength, insulation, and durability. They consist of an extruded polystyrene (XPS) foam core securely sandwiched between rigid skins such as fiberglass reinforced plastic (FRP), aluminum, plywood, or steel. This unique structure combines the benefits of lightweight insulation with high structural integrity, making them ideal for a wide range of applications.

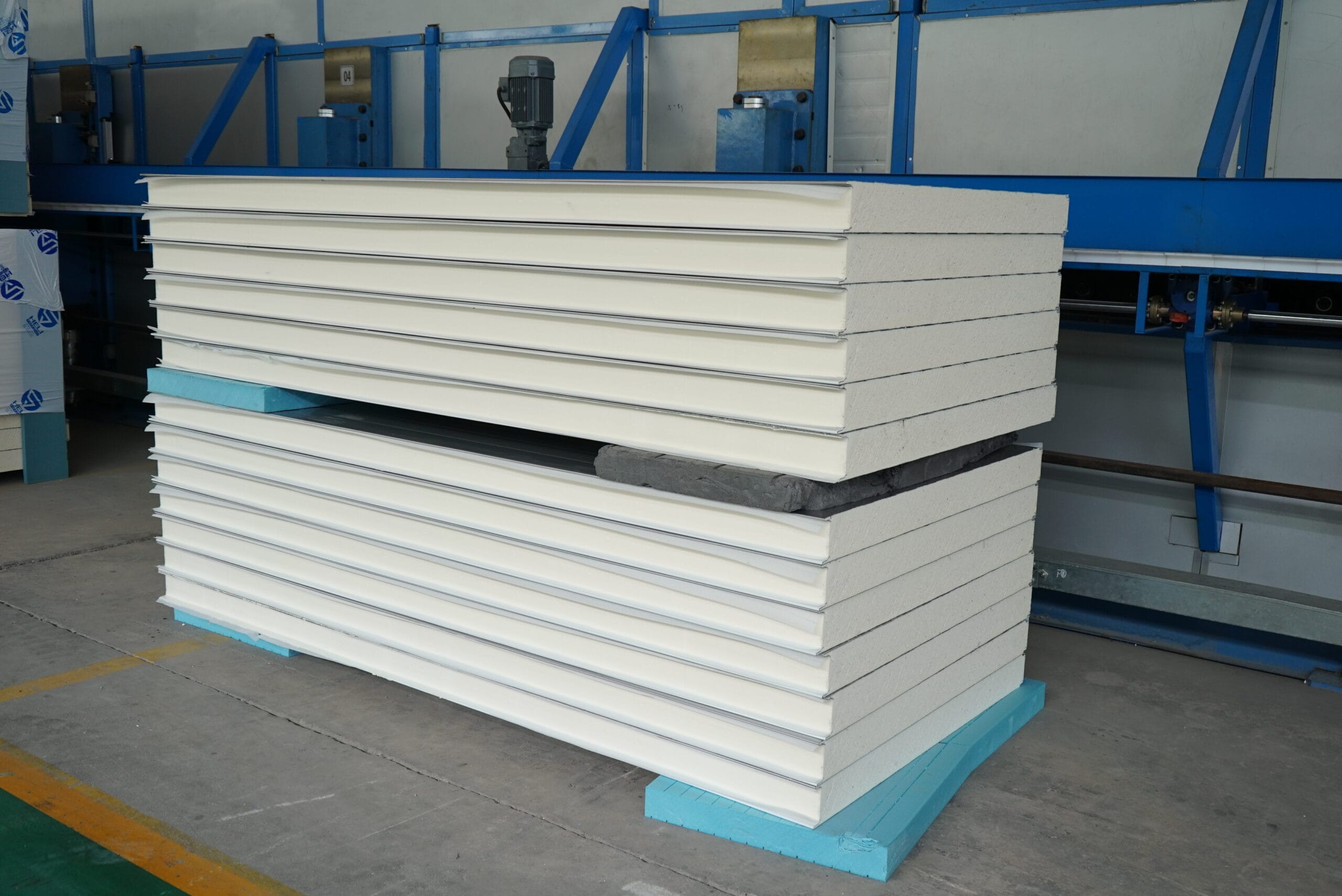

Customers visit the factory

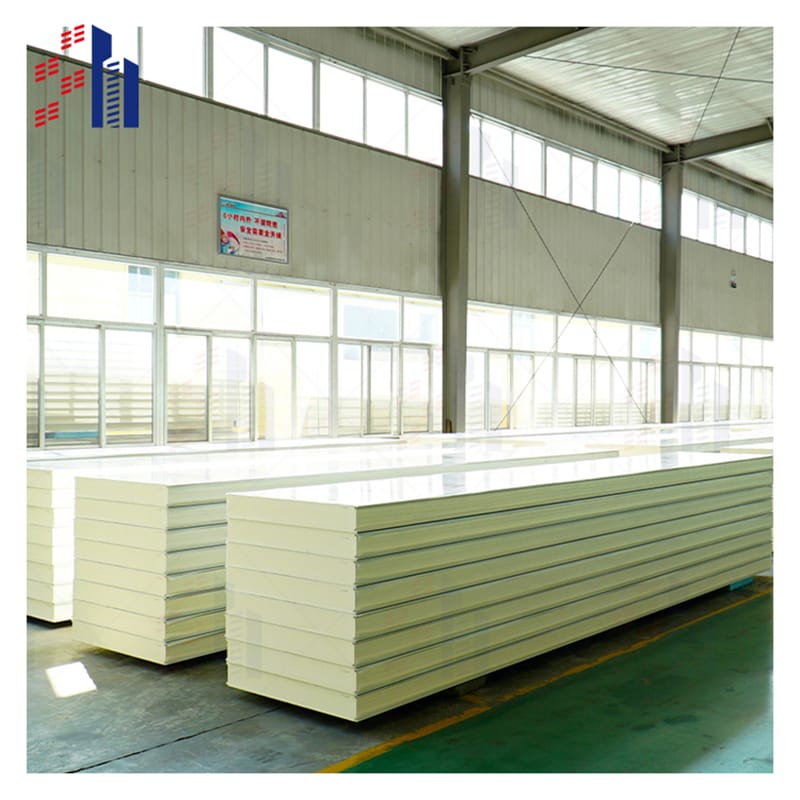

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Foamed Pcw |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Manufacturing Process of XPS Foam Sandwich Panels

The core of these panels is produced by an extrusion process, where polystyrene beads are melted and formed into a dense, closed-cell foam with consistent thickness and exceptional moisture resistance. This extruded foam boasts a fine, uniform cellular structure critical to achieving high compressive strength and low thermal conductivity.

Once the XPS core is prepared, it is bonded to the outer skins using vacuum compression bonding technology. This process applies controlled pressure and heat to ensure a strong, uniform adhesion between the foam core and the skin materials. The result is a highly durable panel with excellent impact resistance and dimensional stability, capable of withstanding harsh conditions without delamination.

Key Features of XPS Foam Sandwich Panels

- Lightweight: Thanks to the low-density XPS core, these panels offer a significant weight reduction compared to traditional solid materials.

- High Compressive Strength: The closed-cell foam provides superior load-bearing capacity, making the panels suitable for structural applications.

- Thermal Insulation: XPS has a very low thermal conductivity, contributing to energy-efficient building envelopes and transportation insulation.

- Moisture Resistance: The closed-cell structure prevents water absorption and resists mold, ensuring long-term performance in humid or wet environments.

Together, these features make XPS foam sandwich panels a reliable choice for industries seeking a balance of strength, insulation, and moisture resistance in lightweight construction materials.

Benefits of XPS Foam Sandwich Panels

Excellent Thermal Insulation

XPS foam sandwich panels offer low thermal conductivity, making them perfect for energy-efficient buildings and vehicles. Their extruded polystyrene foam core traps air effectively, helping maintain consistent indoor temperatures and reducing heating and cooling costs.

Lightweight Design for Easy Handling

These panels are lightweight, which is a major advantage for RVs, trucks, and mobile homes. Reducing overall weight improves fuel efficiency and handling without compromising on strength, making XPS foam sandwich panels a smart choice for transportation and mobile living applications.

Superior Moisture Resistance

Thanks to their closed-cell structure, XPS foam panels resist water absorption and moisture build-up. This feature prevents mold, mildew, and structural damage, particularly valuable in humid environments or applications exposed to moisture like refrigerated truck bodies and cold storage rooms.

High Durability and Strength

XPS core provides high compressive strength, supporting heavy loads and ensuring long-term durability. When combined with strong skins like FRP, aluminum, or plywood, these panels withstand harsh conditions and maintain structural integrity in demanding construction and transportation uses.

Eco-Friendly and Sustainable

Many XPS foam sandwich panels incorporate recyclable materials like aluminum skins, and are made with sustainability in mind. Shanghe focuses on sourcing eco-friendly raw materials and designing panels that meet strict environmental standards, helping reduce your project’s carbon footprint.

How Shanghe Enhances These Benefits

Shanghe uses advanced manufacturing techniques, including vacuum compression bonding and precise CNC machining, to ensure every XPS foam sandwich panel performs at its best. High-quality adhesives and skin materials improve panel strength, moisture resistance, and insulation, tailored specifically to your project needs. This commitment to quality means you get reliable, durable panels built to last in real-world American conditions.

Applications of XPS Foam Sandwich Panels

XPS foam sandwich panels are a versatile solution used across several industries, thanks to their strength, insulation, and lightweight properties. Below are key areas where these panels excel:

Construction

These panels are widely used as wall panels, roofing, and insulation materials in energy-efficient buildings. Their excellent thermal insulation helps reduce heating and cooling costs, making homes and commercial properties more sustainable and comfortable.

Transportation

In the transportation sector, XPS foam sandwich panels are ideal for truck bodies, RV panels, and marine components. Their lightweight design improves fuel efficiency, while their durability ensures long-lasting use in demanding conditions.

Cold Storage

XPS foam sandwich panels are perfect for refrigerated trucks and cold rooms, offering reliable temperature control. The closed-cell foam core prevents moisture buildup, keeping products safe and preserving cold chain efficiency.

Other Uses

These panels are also used in mobile homes, temporary structures, and signage, where quick installation and effective insulation are essential.

Shanghe’s Industry Experience

At Shanghe, we specialize in customizing XPS foam sandwich panels tailored to your industry needs. Whether you require specific skin materials like FRP, aluminum, or plywood, or particular panel thicknesses and sizes, we deliver solutions that meet performance standards and local market demands across the U.S.

With advanced manufacturing techniques and quality materials, Shanghe ensures each panel fits the exact purpose—whether it’s for construction, transportation, or cold storage applications.

Why Choose Shanghe XPS Foam Sandwich Panels

When it comes to XPS foam sandwich panels, Shanghe stands out with its focus on quality, versatility, and customer satisfaction. Here’s why choosing Shanghe makes a difference:

Customization Options to Fit Your Needs

Shanghe offers a wide range of panel sizes and specifications to suit various applications. You can select from different:

- Widths and thicknesses tailored to your project

- Skin materials such as FRP, aluminum, plywood, and even steel options

- Color finishes for aesthetic and functional purposes

This flexibility ensures the right panel for construction, transportation, cold storage, or custom uses.

Advanced Manufacturing Technology

Shanghe uses state-of-the-art techniques like:

- Vacuum compression bonding to ensure a strong, lasting bond between XPS foam core and skins

- CNC machining for precise cuts and dimension control

- High-quality adhesives that enhance panel durability

These technologies result in lightweight but robust sandwich panels with superior thermal insulation and moisture resistance.

Commitment to Sustainability

In the US market, eco-friendliness is crucial. Shanghe integrates:

- Use of recyclable materials like aluminum skins and eco-friendly adhesives

- Sustainable sourcing practices to reduce environmental impact

- Panels designed for long service life, minimizing waste and replacement

You get a panel solution that not only performs well but supports green building standards.

Global Reach with Reliable Support

Shanghe serves customers worldwide, including across the United States, offering:

- Fast delivery to meet tight project timelines

- Reliable customer support for technical guidance and after-sales service

- Tailored solutions for local climates and industry requirements

This global infrastructure ensures your order arrives on time, ready for use.

Proven Performance Through Customer Success

Many clients trust Shanghe for critical applications like refrigerated truck bodies, RV insulation panels, and cold room walls. Their testimonials and case studies highlight:

- Enhanced thermal efficiency and energy savings

- Longevity and durability in demanding environments

- Customized design support that fits unique project specs

Choosing Shanghe means partnering with a manufacturer that backs its XPS foam sandwich panels with proven results and expert service.

With these advantages, Shanghe’s XPS foam sandwich panels deliver reliable, high-performance solutions that meet the diverse needs of modern American industries.

Comparing XPS Foam Sandwich Panels to Other Materials

When choosing the right insulation and structural panel, it helps to understand how XPS foam sandwich panels stack up against alternatives like EPS and PIR foam, along with the various skin materials available.

XPS vs EPS Foam Panels

- Better moisture resistance: XPS (extruded polystyrene) has a closed-cell structure, which means it absorbs far less water than EPS (expanded polystyrene). This makes XPS panels ideal for humid or wet environments.

- Higher compressive strength: XPS foam offers stronger load-bearing capacity, so it holds up better under pressure, making it a more durable option for construction and transportation applications.

- Consistent thermal insulation: While EPS is a good insulator, XPS maintains its insulation properties longer, especially when exposed to moisture.

XPS vs PIR Foam Panels

- More cost-effective: PIR (polyisocyanurate) foam provides excellent thermal performance but comes at a higher price point. XPS panels deliver comparable insulation at a lower cost, making them a practical choice for many projects.

- Balance of performance and price: For applications like wall panels, roofing, or refrigerated trucks, XPS offers a great balance of insulation efficiency and affordability.

Skin Material Options for XPS Foam Sandwich Panels

Shanghe offers a variety of skin materials to fit different needs. Here’s a quick look at each:

- FRP (Fiberglass Reinforced Plastic)

- Pros: Lightweight, corrosion-resistant, and easy to handle.

- Cons: Less impact-resistant than metal skins.

- Best for: Marine, RV panels, temporary structures.

- Aluminum Skins

- Pros: Lightweight, corrosion-resistant, and excellent for outdoor use.

- Cons: Can dent if subjected to heavy impact.

- Best for: Cold storage, refrigerated truck bodies, and energy-efficient buildings.

- Plywood Skins

- Pros: Strong, impact-resistant, easy to work with.

- Cons: Heavier and less moisture-resistant than metals or FRP.

- Best for: Interior walls, mobile homes, and temporary facilities where weight is less of a concern.

- Steel Skins

- Pros: Extremely durable and strong with high impact resistance.

- Cons: Heavier and prone to rust if not coated properly.

- Best for: Industrial applications and heavy-duty transportation.

Shanghe’s Versatile Combinations

At Shanghe, we pair XPS foams with a variety of skins tailored to your exact industry needs. Whether you need a lightweight FRP panel for RV insulation or a tough aluminum skin for refrigerated truck walls, we customize each panel for:

- Precise thickness and density of XPS foam core.

- Skin material selection based on environmental exposure.

- Panel size and edge design for easy installation and maximum performance.

This flexibility lets you get the best out of extruded polystyrene sandwich panels for better insulation, durability, and moisture resistance—perfect for the diverse conditions in the US market.

How to Choose the Right XPS Foam Sandwich Panel

Selecting the perfect XPS foam sandwich panel is all about matching the panel’s features to your specific needs. Here’s what you should consider:

Key Factors to Consider

- Application: Identify where the panel will be used. Different uses—like wall insulation, roofing, refrigerated truck panels, or RV insulation—demand different properties.

- Thickness: Choose the right foam core thickness based on the thermal insulation required and expected load-bearing needs. Thicker cores offer better insulation but add weight.

- Skin Material: Decide between FRP, aluminum, plywood, or steel skins. Aluminum skins provide excellent durability and corrosion resistance, FRP offers lightweight flexibility, and plywood can be cost-effective for certain structural uses.

- Environmental Conditions: Consider exposure to moisture, temperature extremes, and UV radiation. XPS foam’s closed-cell structure already offers moisture resistance but pairing it with the right skin enhances performance in harsh environments.

Installation Tips for Optimal Performance

Getting the installation right is crucial to making the most out of your XPS sandwich panels:

- Proper Adhesion: Use high-quality adhesives compatible with both the foam core and skin material to ensure a tight bond and long-lasting panel integrity.

- Sealing Joints: Seal panel seams carefully to prevent air or moisture infiltration, maintaining insulation efficiency and avoiding damage.

- Cutting Panels: Cut panels cleanly using appropriate tools to avoid fracturing the foam core or damaging the skins. Precise cutting ensures tight fits and better sealing.

Shanghe’s Expert Consultation and Support

When you need help picking the right panel or want custom specifications:

- Tailored Solutions: Shanghe offers expert consultation to recommend panels based on your project’s size, purpose, and conditions.

- Technical Support: Get assistance with installation guidelines, maintenance tips, and after-sale services to ensure your panels perform as promised.

- Customized Options: From custom thickness and width to skin materials and colors, Shanghe can tailor XPS foam sandwich panels to your exact requirements.

Choosing the right XPS foam sandwich panel means balancing insulation, strength, and environmental resistance. With proper selection and professional support from Shanghe, you can ensure you get the performance and durability your project demands.

FAQs About XPS Foam Sandwich Panels

What are the standard sizes of XPS foam sandwich panels

XPS foam sandwich panels typically come in standard widths of 24 to 48 inches and lengths from 8 to 20 feet. Thickness varies widely depending on the application, usually ranging from 1 inch up to 4 inches or more for enhanced insulation and strength. Custom sizes are often available to fit specific project needs, especially in construction, transportation, and cold storage industries.

Are XPS foam sandwich panels suitable for outdoor use

Yes, XPS foam sandwich panels are well-suited for outdoor applications. Thanks to their closed-cell structure, they resist moisture absorption, making them ideal for humid, rainy, or challenging weather conditions. When paired with durable skins like aluminum or FRP, these panels withstand UV exposure and environmental wear, ensuring long-lasting performance for roofing, wall cladding, and vehicle exteriors.

Are XPS foam sandwich panels recyclable

Many XPS foam sandwich panels incorporate recyclable materials, including aluminum skins and environmentally friendly adhesives. The foam core itself is made of extruded polystyrene, which can be recycled in specialized facilities. Choosing panels with sustainable sourcing and recyclable components helps reduce environmental impact, aligning with eco-conscious building and manufacturing practices common in the US market.

How do XPS foam sandwich panels perform in extreme temperatures

XPS foam sandwich panels deliver excellent thermal insulation across a wide temperature range, making them a top choice for cold storage, refrigerated trucks, and harsh climates. Their low thermal conductivity helps maintain stable interior temperatures in freezing or hot conditions, ensuring energy efficiency and protecting sensitive goods or interiors. Moreover, these panels retain their strength and durability without warping or degrading under temperature extremes typical in the US.

- Standard sizes: 24-48″ wide, 8-20′ length, 1-4″+ thickness

- Outdoor use: Yes, moisture and UV resistant with proper skins

- Recyclability: Components mostly recyclable, eco-friendly options available

- Temperature performance: Strong insulation for cold and hot environments

If you’re looking for custom options or technical advice on choosing the right XPS foam sandwich panels for your project, Shanghe offers expert consultation and support tailored to your needs.