What Are Lightweight Sandwich Panels

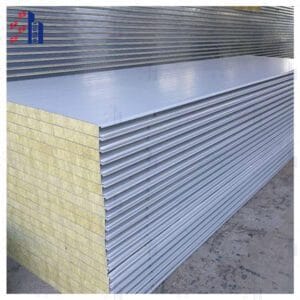

Lightweight sandwich panels are composite materials made by bonding two strong outer layers, called skins, to a lightweight core. This design gives you a panel that is both strong and light—perfect for many construction and industrial uses.

Core Materials

The core is the heart of the panel, providing insulation and strength without adding much weight. Common core materials include:

- Polyurethane (PU) – great for thermal insulation and durability

- Polystyrene (EPS and XPS) – popular foam options offering good insulation and moisture resistance

- Honeycomb structures – often made from aluminum or paper, used for high strength-to-weight needs

- Foam concrete – a lightweight, fire-resistant option for specific applications

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification (Metric) | U.S. Standard | Why It Matters |

|---|

| Core Material | PIR (Polyisocyanurate) | ASTM E84 Class A | Stops fires + cuts cooling costs by 40% |

| Fire Rating | A1 (Non-combustible) | UL 94 V-0 | Meets NYC high-rise codes – no toxic smoke |

| Thickness | 50mm, 75mm, 100mm | – | 100mm = -40°F freezer compliance (ASHRAE) |

| Thermal Conductivity (λ) | 0.022 W/m·K | R-6.5 per inch | Beats fiberglass (R-3.7) – cheaper long-term |

| Panel Strength | 150 kPa compressive | ASTM C165 | Walkable roof loads (25 psf) – no dents |

| Custom Sizes | Up to 40ft x 4ft | – | Fewer seams = faster install + better insulation |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | steel foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Skin Materials

The outer skins protect the core and add rigidity. They come in various materials depending on the application:

- Steel – strong and durable, ideal for industrial and commercial buildings

- Aluminum – lightweight and corrosion-resistant, common in aerospace and automotive

- Fiberglass Reinforced Plastic (FRP) – offers corrosion resistance and design flexibility

- Wood-based materials – used for eco-friendly and aesthetic applications

Shanghe’s Unique Approach

At Shanghe, we focus on quality and flexibility. We use high-quality core and skin materials to ensure every panel performs well in strength, insulation, and durability. Plus, our panels are customizable to fit the specific needs of your project, whether you need special sizes, finishes, or materials.

Explore our range of polyurethane sandwich panels and aluminum sandwich panels to see how we combine core and skin materials for top performance.

Benefits of Lightweight Sandwich Panels

Lightweight sandwich panels offer an impressive strength-to-weight ratio, giving you strong, rigid structures without the heavy bulk. This makes them perfect for projects where minimizing weight is key, like in construction or transportation.

They also provide excellent thermal insulation, helping buildings stay energy efficient. Whether it’s for walls, roofs, or cold storage units, these panels keep temperatures stable and reduce energy costs.

Sustainability is another big plus. Many panels use eco-friendly, recyclable materials, so you can build green without sacrificing performance. This aligns well with growing US demand for sustainable building solutions.

Cost effectiveness comes from faster installation and lower labor costs. Since these panels are lightweight and easy to handle, your project timeline shortens, saving money overall.

Durability is built in too. These panels resist corrosion, fire, and harsh environmental conditions, making them reliable for long-term use.

What sets Shanghe apart is our eco-conscious manufacturing and ability to tailor panels to local US market needs. We focus on delivering solutions that meet regional building codes and climate challenges, ensuring you get the best value and performance.

Types of Lightweight Sandwich Panels

Lightweight sandwich panels come in different types, each designed for specific needs and industries.

Honeycomb panels

These panels use a honeycomb core, making them super strong but still lightweight. They’re perfect for aerospace and automotive parts where strength and weight savings are critical.

Foam core panels

Made with cores like polyurethane (PU), expanded polystyrene (EPS), or extruded polystyrene (XPS), these panels offer excellent insulation. They’re widely used in construction for walls, roofs, and cold storage.

Corrugated panels

With a unique corrugated core, these panels provide extra load-bearing capacity. They’re ideal for industrial buildings and applications where durability under heavy use matters.

Bio based panels

For those looking for greener options, bio based panels use materials like wood or hemp cores. These sustainable panels are gaining traction in eco-friendly building projects.

Shanghe’s range

We offer customizable lightweight sandwich panels tailored to fit specific industries and local climate needs, ensuring you get the right balance of strength, insulation, and sustainability.

Applications of Lightweight Sandwich Panels

Lightweight sandwich panels are incredibly versatile and used across many industries in the U.S. Here’s where they shine:

- Construction: Perfect for walls, roofs, and facades, these panels boost energy efficiency in homes and commercial buildings. Their insulation properties help reduce heating and cooling costs, making them a smart choice for sustainable urban projects.

- Aerospace: The aerospace industry relies on honeycomb core panels for lightweight, strong components that improve fuel efficiency without compromising safety.

- Automotive: Especially in electric vehicles, lightweight sandwich panels help offset the heavy battery weight, improving range and performance.

- Marine: These panels resist corrosion and environmental wear, making them ideal for shipbuilding and marine structures that need durability in harsh conditions.

- Cold Storage: Insulated foam core panels are widely used in warehouses and refrigeration units to maintain temperature control efficiently.

- Local Relevance: In U.S. urban areas, there’s a growing focus on sustainable building materials. Lightweight sandwich panels fit right in, supporting regional construction trends toward greener, more energy-efficient buildings.

- Shanghe Case Study: For example, Shanghe supplied customized sandwich panels for a local commercial building in California. The project benefited from reduced installation time, superior insulation, and panels tailored to withstand the coastal climate’s humidity and salt exposure.

These applications show why lightweight sandwich panels are a go-to solution for modern, efficient, and sustainable building and manufacturing needs.

Why Choose Shanghe Lightweight Sandwich Panels

When you choose Shanghe lightweight sandwich panels, you’re getting top-notch quality backed by rigorous testing. Each panel goes through strict checks for mechanical strength and fire resistance, so you can trust they’ll perform when it counts.

Customization is a big plus with Shanghe. Whether you need specific dimensions, materials, or finishes, they tailor panels to fit your exact project needs. This means you get the perfect fit without compromise.

Sustainability is also a priority. Shanghe uses recyclable and bio-based materials whenever possible, helping reduce environmental impact while still delivering durable, high-performance panels.

Local support makes a difference too. Shanghe offers fast delivery and expert consultation tailored for customers across the U.S., ensuring you get the right lightweight sandwich panels for your region’s climate and building codes.

Ready to upgrade your project? Contact Shanghe today for a quote or product catalog and see how their lightweight sandwich panels can work for you.

How to Select the Right Lightweight Sandwich Panel

Choosing the right lightweight sandwich panel starts with understanding your project needs. Ask yourself:

- What’s the main purpose? Do you need strong load-bearing panels, excellent insulation, or a specific look?

- What’s the environment like? Consider local climate, salt exposure near coasts, or seismic activity that might affect panel performance.

- Which materials fit best? Different core materials like polyurethane (PU), EPS, or honeycomb, and skins like steel or fiberglass, work better for certain uses.

- What’s your budget? Look beyond upfront costs and think about long-term savings from energy efficiency and durability.

At Shanghe, we offer a free consultation to help you pick the perfect panel based on your goals and local conditions. This way, you get a solution that’s cost-effective, sustainable, and built to last.