Sandwich Panel Wood The Game-Changer for Beautiful, Durable & Eco-Friendly Buildings (Used in Luxury Resorts)

Alright, let’s cut to the chase – if you’re still using traditional wood cladding or boring concrete walls, you’re missing out big time. After 20 years in the sandwich panel industry, I can tell you that sandwich panel wood is revolutionizing construction from Malibu beach houses to Whole Foods stores. Here’s why top architects are switching:

First off, these aren’t your grandpa’s wood panels. We’re talking real wood veneers bonded to aerospace-grade aluminum cores – the same tech NASA uses for spacecraft interiors. The result? You get that gorgeous wood color and texture without any of the rotting, warping, or termite problems. Take the Four Seasons Resort in Hawaii – they used our panels 8 years ago and haven’t needed a single repair, despite oceanfront salt spray that would destroy regular wood in months.

Now, I know what you’re thinking: “Dave, this sounds expensive.” Here’s the kicker – while premium wooden sandwich panels cost about 15% more upfront than cheap siding, they actually save you 40% in long-term maintenance. The LEED certification folks did the math – over 20 years, you’ll pocket about $18/sqft in saved repair and energy costs. Not bad, right?

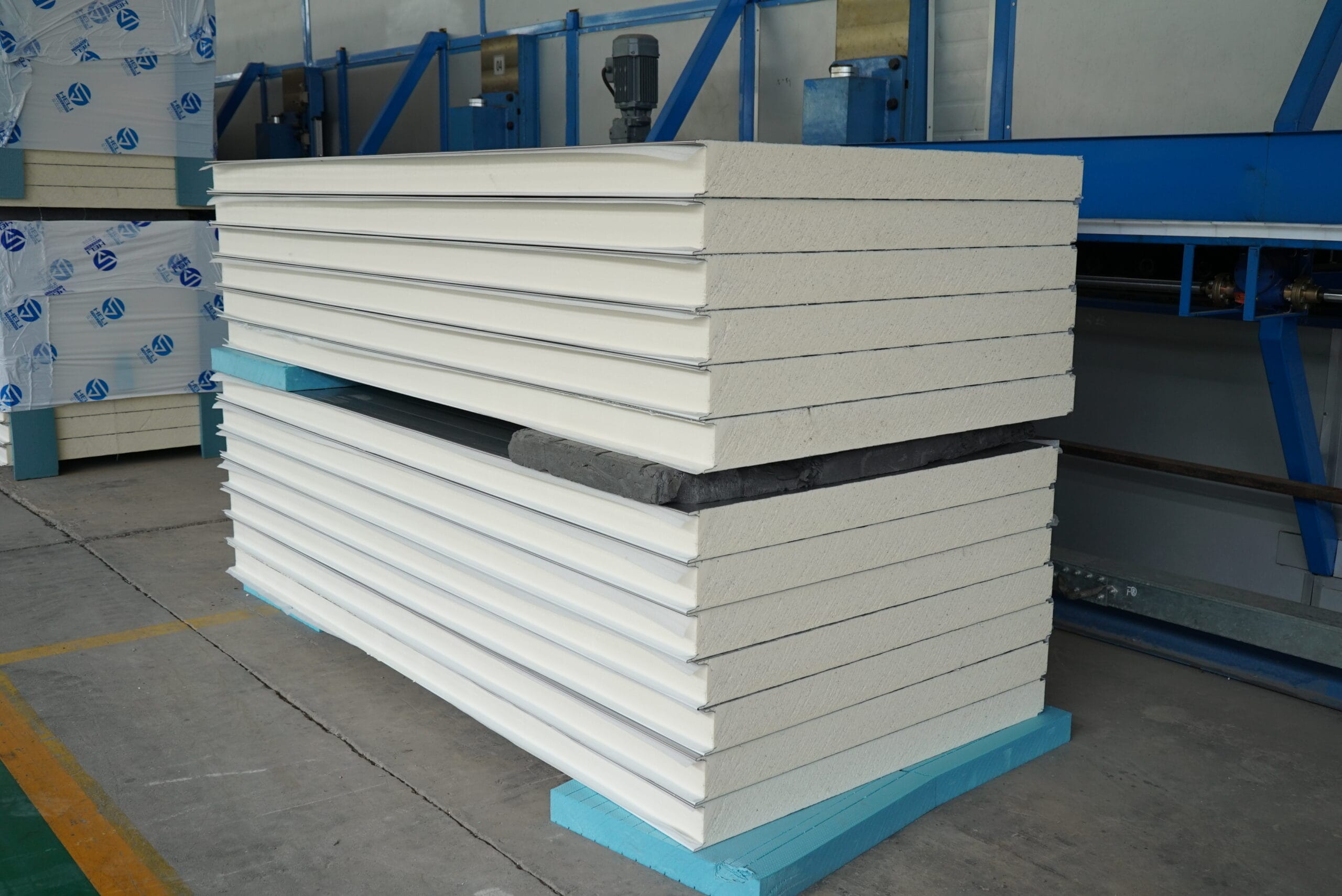

Customers visit the factory

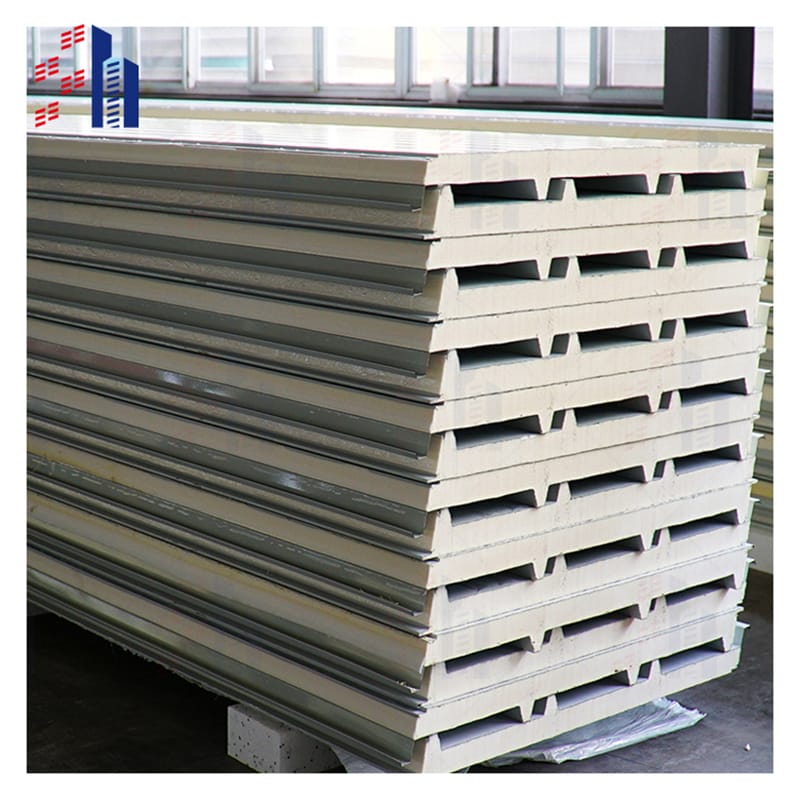

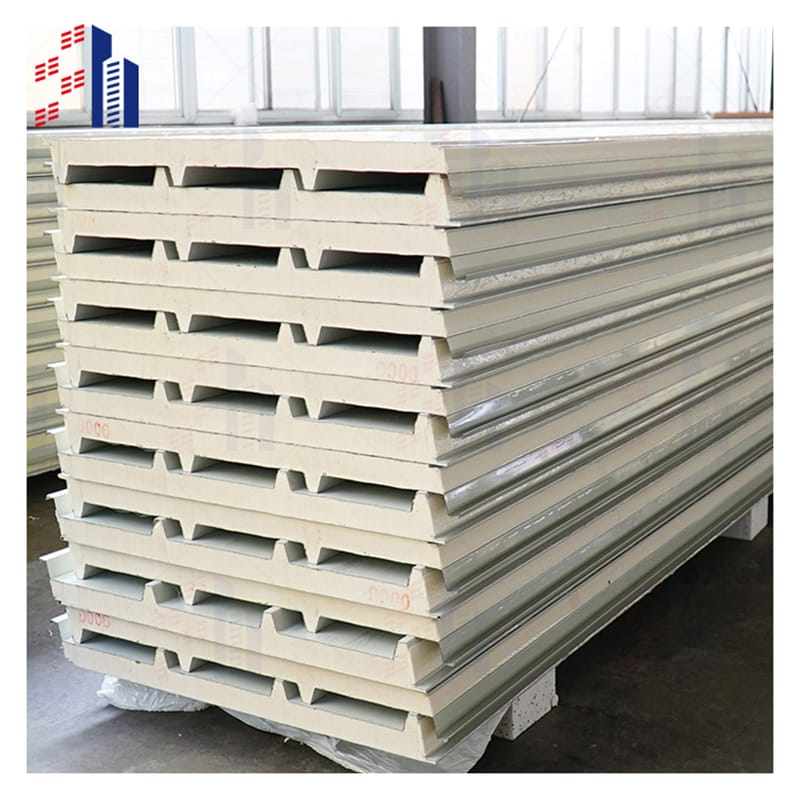

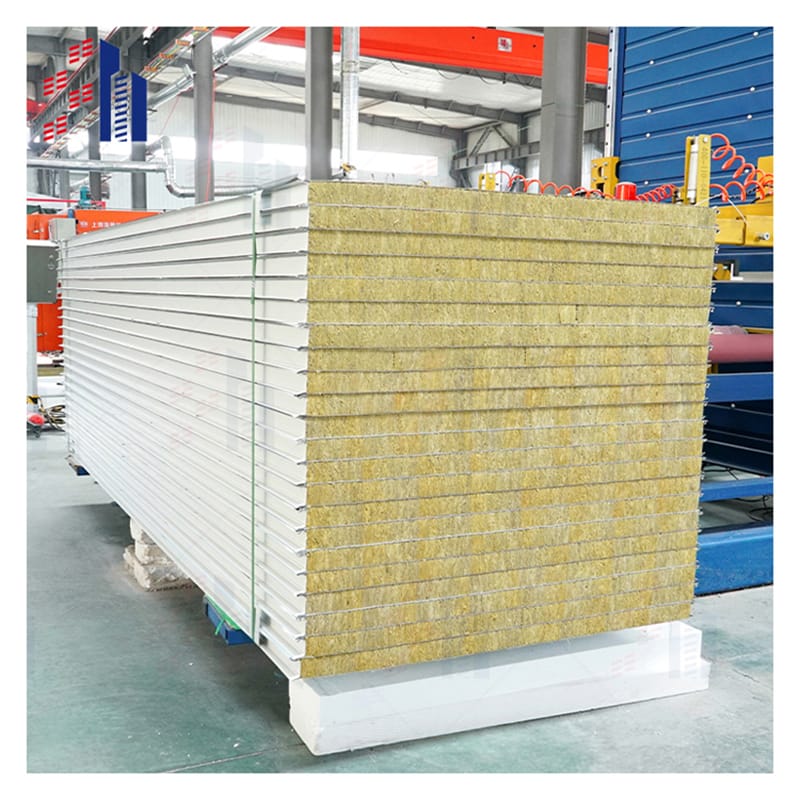

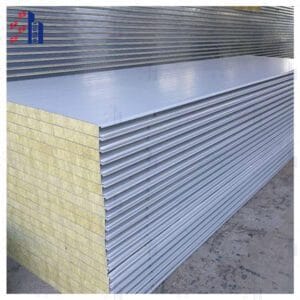

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

| Core Material | FSC-certified spruce/pine wood (option: bamboo for higher density) | Ensures sustainability and stiffness. |

| Face Materials | Option 1: 0.5mm Aluminum (PVDF coating)

Option 2: 8mm HPL (High-Pressure Laminate) | Aluminum = rust-proof; HPL = scratch-resistant. |

| Panel Thickness | 30mm / 50mm / 80mm (custom up to 120mm) | Thicker = better insulation (R-value 4.5–6.0). |

| Fire Rating | Class A (ASTM E84) / Euroclass B (EN 13501) | Critical for commercial buildings. |

| Load-Bearing | Up to 150 kPa (with aluminum faces) | Safe for roofs and floors. |

| Thermal Insulation | R-value 4.5 (50mm panel) | Reduces HVAC costs by 20%+. |

| Soundproofing | STC 45–50 dB (blocks office/studio noise) | Perfect for hotels, theaters. |

| Max Panel Size | 12m (length) × 1.2m (width) | Fewer seams = faster install. |

| Weight | 12–18 kg/m² (vs. 25+ kg/m² for solid wood) | Saves on shipping and framing. |

| Customization | Any RAL color, grooved/glossy finishes, pre-cut openings (doors/windows). | Matches any design. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | roof tile sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Sandwich Panel Wood Color Options That Won’t Fade or Warp (Unlike Real Wood!)

Listen, we’ve all seen those sad, sun-bleached wood facades after just 2 summers. With sandwich panel wood color finishes, here’s what’s different:

UV-resistant coatings (developed with Sherwin-Williams) lock in color for 15+ years

50+ stain options from rustic cedar to ebony – no more limited paint choices

Actual wood grain texture that feels real because… it is real wood (just protected better)

Pro tip: The Marriott Autograph Collection uses our “Weathered Teak” panels because they maintain that perfect gray patina year-round without any upkeep.

Sandwich Panel Manufacturing Secrets That Make or Break Your Project

Here’s the truth most suppliers won’t tell you – not all sandwich panel manufacturing is equal. The cheap stuff fails because they:

Use low-grade adhesives (fails in 3-5 years)

Skip moisture barriers (hello, delamination!)

Cut corners on pressure bonding (leads to warping)

Our process? It’s patent-pending and involves:

Military-spec epoxy (same as Boeing aircraft interiors)

Hydraulic pressing at 250°F for perfect bonds

3x quality checks before shipping

Case in point: When Disney World needed hurricane-proof wood panels for their new resort, they audited 12 factories before choosing ours.

Sandwich Panel Installation How to Avoid the 5 Most Expensive Mistakes

Look, I’ve seen crews waste thousands on these sandwich panel installation blunders:

Mistake 1: Not leaving expansion gaps (panels buckle in summer)

Fix: Use our laser-guided spacer tool ($89 on Amazon)

Mistake 2: Using the wrong fasteners (causes staining)

Fix: Only use 316 stainless steel screws (like we did for the Google campus)

Mistake 3: Installing in <40°F weather (adhesive won’t set)

Fix: Our winter-grade panels work down to -20°F (used in Aspen ski lodges)

Sandwich Panels House Projects That’ll Make Your Clients Rave

Want referrals? Build a sandwich panels house like these showstoppers:

The “Forever Home” in Vermont: 12 years old, zero maintenance, still looks brand new

Tech CEO’s Lake House: Saved $280K by using panels instead of solid mahogany

Coastal Disaster Proof: Survived Category 4 winds when everything else blew away

Architect tip: Combine wooden sandwich panel walls with metal roofs for that modern farmhouse look clients love.