What Are Structural Sandwich Panels Definition core materials and key characteristics

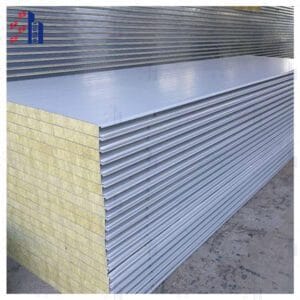

Structural sandwich panels are composite sandwich panels made by bonding two strong outer layers to a lightweight core material. This design creates lightweight structural panels that offer excellent strength and stiffness without adding much weight. The core materials commonly used include foam core sandwich panels, honeycomb core panels, and structural insulated panels (SIPs). These cores provide insulation, impact resistance, and load distribution, while the outer skins—often made from metals, fiberglass, or composite materials—deliver durability and surface protection.

Key characteristics of structural sandwich panels include:

- High strength-to-weight ratio: They provide strong support while remaining lightweight.

- Thermal insulation: The core materials help reduce heat transfer, making them energy-efficient.

- Durability: Resistant to corrosion, moisture, and environmental damage.

- Flexibility in design: Panels can be customized for different thicknesses, sizes, and mechanical properties.

- Ease of installation: Their lightweight nature simplifies handling and speeds up construction.

These panels are widely used where strong, lightweight, and insulated materials are needed, making them a popular choice in modern construction and engineering projects.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification (Metric) | U.S. Standard | Why It Matters |

|---|

| Core Material | PIR (Polyisocyanurate) | ASTM E84 Class A | Stops fires + cuts cooling costs by 40% |

| Fire Rating | A1 (Non-combustible) | UL 94 V-0 | Meets NYC high-rise codes – no toxic smoke |

| Thickness | 50mm, 75mm, 100mm | – | 100mm = -40°F freezer compliance (ASHRAE) |

| Thermal Conductivity (λ) | 0.022 W/m·K | R-6.5 per inch | Beats fiberglass (R-3.7) – cheaper long-term |

| Panel Strength | 150 kPa compressive | ASTM C165 | Walkable roof loads (25 psf) – no dents |

| Custom Sizes | Up to 40ft x 4ft | – | Fewer seams = faster install + better insulation |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | steel foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why Choose Structural Sandwich Panels Benefits comparison and Shanghe’s value proposition

Structural sandwich panels offer a smart mix of strength and lightweight design that traditional materials often can’t match. Compared to solid panels, these composite sandwich panels use core materials like foam or honeycomb to deliver high strength without the heavy weight. This means easier handling, faster installation, and lower transportation costs—big wins for construction and manufacturing projects.

Here’s why structural sandwich panels stand out:

- Lightweight yet strong: The core materials provide excellent stiffness and load-bearing capacity.

- Energy efficient: Structural insulated panels (SIPs) help with better insulation, cutting down heating and cooling costs.

- Durable and resistant: These panels resist moisture, corrosion, and impact better than many traditional materials.

- Versatile design: They can be customized to fit different shapes, sizes, and performance needs.

At Shanghe, we bring these benefits together with our commitment to quality and service. Our panels are made with eco-friendly building materials that meet U.S. standards, ensuring your projects stay sustainable without compromising on performance. Plus, we offer competitive pricing and expert support to help you choose the right panel for your needs. Whether you’re in construction, aerospace, or marine industries, Shanghe’s structural sandwich panels deliver reliable, high-strength composite structures that work for you.

Applications of Structural Sandwich Panels Construction and Architecture

Structural sandwich panels are a game-changer in construction and architecture across the U.S. They offer lightweight structural panels that make building faster and more efficient without sacrificing strength. These panels often use foam core sandwich panels or honeycomb core panels, providing excellent insulation and durability.

You’ll find them in walls, roofs, and floors of commercial buildings, schools, and homes. Their high-strength composite structures help improve energy efficiency, making them ideal for eco-friendly building materials. Plus, sandwich panel construction reduces material waste and labor costs, which is a big win for contractors and developers.

Whether it’s a modern office building or a sustainable residential project, structural insulated panels (SIPs) from Shanghe deliver reliable performance and easy installation, meeting the demands of today’s construction market.

Applications of Structural Sandwich Panels Aerospace and Automotive

Structural sandwich panels are a game-changer in aerospace and automotive industries. Their lightweight design combined with high strength makes them perfect for improving fuel efficiency and performance. In airplanes, honeycomb core panels and foam core sandwich panels reduce overall weight without sacrificing safety or durability. This means better range and lower emissions.

In cars and trucks, these composite sandwich panels help manufacturers build lighter frames and body parts. That leads to faster acceleration, improved handling, and better gas mileage. Plus, structural insulated panels (SIPs) offer excellent impact resistance, which boosts passenger safety.

Using sandwich panel construction in aerospace and automotive also speeds up production. The panels are easier to assemble and customize, fitting well with modern manufacturing needs. For U.S. companies aiming to compete globally, these panels provide a smart balance of strength, weight, and cost-effectiveness.

Applications of Structural Sandwich Panels Marine and Industrial Applications

Structural sandwich panels are a great fit for marine and industrial uses because they combine strength with lightweight design. In boats and ships, these panels help reduce weight without sacrificing durability, improving fuel efficiency and overall performance. Common core materials like honeycomb and foam cores offer excellent resistance to moisture and corrosion, which is critical in harsh marine environments.

In industrial settings, these panels provide strong insulation and structural support for factories, warehouses, and cold storage facilities. Their high-strength composite structures stand up well to heavy loads, impact, and temperature changes, making them reliable for tough conditions. Plus, they’re easy to install and maintain, saving time and costs over traditional materials.

Key benefits for marine and industrial applications:

- Lightweight but tough, improving efficiency and durability

- Resistant to moisture, corrosion, and chemicals

- Excellent thermal and sound insulation

- Easy to handle and install on-site

- Long-lasting performance in demanding environments

Using structural sandwich panels in these sectors means you get a smart, cost-effective solution that meets the high standards of safety and performance required in the U.S. market.

Technical Insights into Structural Sandwich Panels Design and Manufacturing Process

Structural sandwich panels are engineered by bonding two strong outer layers to a lightweight core, creating a composite sandwich panel that offers high strength and low weight. The design starts with selecting the right core material—commonly foam core sandwich panels, honeycomb core panels, or structural insulated panels (SIPs)—each chosen for specific performance needs like insulation, rigidity, or impact resistance.

The manufacturing process involves:

- Core Preparation: Cutting and shaping the core material to fit the panel size and specifications.

- Face Sheet Selection: Choosing durable outer layers, often aluminum, plywood, or fiber-reinforced composites, to provide structural support and surface protection.

- Bonding: Using adhesives or resin to firmly attach the face sheets to the core, ensuring a strong, uniform bond.

- Curing and Pressing: Applying heat and pressure to solidify the bond and eliminate any air gaps, which improves mechanical properties.

- Finishing: Trimming edges and adding surface treatments like fireproofing or weather-resistant coatings.

This process results in lightweight structural panels that deliver excellent mechanical properties while allowing customization based on project requirements. For example, Shanghe offers a range of sandwich panels like XPS foam sandwich panels and aluminium sandwich panels that are designed to meet diverse construction and industrial needs in the U.S. market.

By controlling each step carefully, manufacturers ensure the panels meet strict quality standards, making them ideal for applications where strength, weight, and durability matter.

Technical Insights into Structural Sandwich Panels Mechanical Properties and Performance

Structural sandwich panels are known for their impressive mechanical properties that make them ideal for many demanding applications. These panels combine lightweight materials with high strength, offering excellent stiffness and load-bearing capacity without adding extra weight.

Key mechanical features include:

- High Strength-to-Weight Ratio: Thanks to core materials like honeycomb or foam, these panels deliver strong support while staying lightweight, making them perfect for construction, aerospace, and automotive uses.

- Superior Flexural Stiffness: The sandwich design resists bending and deformation, which ensures durability and stability under stress.

- Impact Resistance: Many sandwich panels can absorb shocks and impacts, protecting structures from damage.

- Thermal Insulation: Besides mechanical strength, panels like foam core sandwich panels also provide good insulation, helping with energy efficiency.

- Fire Resistance: Depending on the core and facing materials, some panels meet fire safety standards, important for building codes in the U.S.

Performance-wise, these panels maintain structural integrity over time, even under harsh environmental conditions like moisture, temperature changes, and UV exposure. This reliability makes them a smart choice for projects that demand long-lasting materials.

For those interested in specific product options, Shanghe offers a range of panels including composite foam sandwich panels and metal sandwich panels that balance mechanical performance with durability and cost-efficiency.

Technical Insights into Structural Sandwich Panels Customization and Optimization

Structural sandwich panels offer a lot of flexibility when it comes to customization and optimization. Depending on your project needs, these composite sandwich panels can be tailored in several ways to boost performance and efficiency.

Here’s how customization works:

- Core Material Choices: You can select from various core materials like foam core sandwich panels, honeycomb core panels, or mineral wool cores. Each offers different strength, weight, and insulation properties.

- Face Sheet Options: The outer layers can be metal, composite, or decorative finishes, allowing you to match aesthetics and durability requirements.

- Panel Thickness and Density: Adjusting thickness and core density helps optimize strength-to-weight ratio, which is crucial for aerospace composite materials or lightweight structural panels used in construction.

- Thermal and Fire Resistance: Panels can be engineered for specific insulation values or fire ratings, perfect for eco-friendly building materials or fireproof sandwich panels.

- Size and Shape: Custom sizes and shapes ensure easy integration into your project, reducing waste and installation time.

At Shanghe, we work closely with you to optimize sandwich panel design, balancing mechanical properties with cost-effectiveness. This means you get the right panel for your application, whether it’s prefab sandwich panels for construction or specialized panels for industrial use.

For example, if you need lightweight sandwich panels with excellent insulation, our foam sandwich panels line might be the perfect fit. Or, if fire resistance is a priority, check out our fire-rated sandwich panel options to meet safety standards without compromising on performance.

By customizing and optimizing structural insulated panels (SIPs), we help you achieve a durable, efficient, and cost-effective solution tailored to your project’s unique demands.

Why Shanghe’s Structural Sandwich Panels Stand Out Eco-Friendly and Sustainable Options

At Shanghe, we know how important eco-friendly building materials are to the U.S. market. That’s why our structural sandwich panels are designed with sustainability in mind. We use core materials like recycled honeycomb cores and foam core sandwich panels made from environmentally responsible sources. This helps reduce waste and lowers the carbon footprint of your projects.

Our panels also offer excellent energy efficiency thanks to their insulation properties, which means less energy use for heating and cooling in buildings. Choosing Shanghe means you’re not just getting lightweight structural panels that perform well—you’re also supporting greener construction practices.

In short, Shanghe’s structural sandwich panels combine strength with sustainability, making them a smart choice for anyone looking to build smarter and cleaner.

Why Shanghe’s Structural Sandwich Panels Stand Out Quality and Durability

When it comes to quality and durability, Shanghe’s structural sandwich panels are built to last. We use top-grade core materials like honeycomb core panels and foam core sandwich panels, combined with strong outer layers to create lightweight structural panels that hold up under tough conditions. This means you get panels that resist wear, impact, and environmental damage better than many alternatives.

Our panels go through strict quality control and testing to meet industry standards, ensuring consistent performance every time. Whether you need panels for construction, aerospace composite materials, or industrial use, Shanghe delivers reliable strength and long service life. Choosing our panels means investing in a product designed to stand up to daily demands while maintaining its shape and function over time.

Why Shanghe’s Structural Sandwich Panels Stand Out Competitive Pricing and Support

When it comes to structural sandwich panels, Shanghe offers competitive pricing without cutting corners on quality. We understand that budget matters, especially for U.S. customers managing construction, aerospace, or industrial projects. Our pricing is designed to give you the best value for lightweight structural panels that deliver strength and durability.

Beyond cost, Shanghe provides reliable support throughout your project. From helping you choose the right composite sandwich panels to answering technical questions, our team is here to guide you. We make sure you get the right sandwich panel construction solution that fits your needs and timeline.

What you get with Shanghe:

- Transparent, fair pricing tailored to your project size

- Responsive customer service based in the U.S. time zones

- Expert advice on foam core sandwich panels, honeycomb core panels, and other options

- Ongoing support from order to delivery and beyond

Choosing Shanghe means you don’t just get a product—you get a partner committed to your project’s success at a price that works.

How to Choose the Right Sandwich Panel for Your Project Factors to Consider

Picking the right structural sandwich panel means matching the panel to your project’s needs. Here are the key factors to keep in mind:

1. Core Material Type

- Foam core sandwich panels offer great insulation and are lightweight.

- Honeycomb core panels provide high strength with minimal weight.

- Structural insulated panels (SIPs) combine strength and energy efficiency.

2. Strength and Load Requirements

- Understand the mechanical loads your panel will face.

- Choose panels designed for high-strength composite structures if you need extra durability.

3. Weight Considerations

- Lightweight structural panels are ideal for projects where reducing weight matters, like aerospace or automotive.

4. Environmental Conditions

- Consider exposure to moisture, temperature changes, and UV light.

- Opt for eco-friendly building materials if sustainability is a priority.

5. Fire Resistance and Safety

- Check fire ratings and compliance with local building codes.

6. Size and Thickness

- Panels come in various thicknesses; thicker panels generally offer better insulation and strength.

7. Budget and Cost Efficiency

- Balance upfront costs with long-term benefits like durability and maintenance.

By focusing on these factors, you’ll ensure your sandwich panel fits your project perfectly, delivering the performance and value you need.

How to Choose the Right Sandwich Panel for Your Project Shanghe’s Expert Guidance

Picking the right structural sandwich panel can feel overwhelming with so many options like honeycomb core panels, foam core sandwich panels, and structural insulated panels (SIPs). That’s where Shanghe steps in to make it simple. We don’t just sell composite sandwich panels—we help you find the perfect fit for your project’s needs.

Here’s how we guide you:

- Understand Your Project Goals: We start by learning what you need—whether it’s lightweight structural panels for aerospace, durable panels for construction, or eco-friendly building materials for a green build.

- Material Selection Advice: Based on your goals, we recommend the best core materials like foam, honeycomb, or other high-strength composite structures that balance strength, weight, and cost.

- Design and Performance Support: Our team helps optimize sandwich panel design to meet mechanical property requirements and ensure long-lasting performance.

- Customization Options: We offer tailored solutions so your panels fit your exact specs, whether that means specific thickness, size, or eco-friendly options.

- Local Market Knowledge: We understand U.S. building codes and industry standards, ensuring your panels comply and perform well in local conditions.

- Ongoing Support: From initial consultation through delivery, we provide expert advice and responsive customer service to keep your project on track.

With Shanghe’s expert guidance, you get more than just panels—you get a partner who knows how to match the right structural sandwich panels to your unique project, saving you time and avoiding costly mistakes.

How to Choose the Right Sandwich Panel for Your Project Get Started with Shanghe

Getting started with Shanghe to find the perfect structural sandwich panel is simple and hassle-free. We understand that every project is unique, so we offer personalized support to help you pick the right composite sandwich panels for your needs. Here’s how to begin:

- Reach Out for a Consultation: Contact our team to discuss your project details, goals, and any specific requirements. We listen carefully to make sure we recommend the best lightweight structural panels for your application.

- Explore Custom Options: Whether you need honeycomb core panels, foam core sandwich panels, or other structural insulated panels (SIPs), we provide tailored solutions that meet your budget and performance needs.

- Get Samples and Technical Support: We can provide product samples and detailed technical info to help you evaluate our panels before making a decision.

- Fast and Reliable Delivery: Once you choose your panels, we ensure quick shipping and ongoing support throughout your project timeline.

At Shanghe, we’re committed to making your sandwich panel selection easy and effective. Start your project with confidence by partnering with experts who know the US market and offer eco-friendly, high-strength composite structures designed to last. Let’s build something great together.